Slice lithium ion battery capable of effectively utilizing battery space

A lithium-ion battery and battery technology, applied in non-aqueous electrolyte battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery space occupation, troublesome processing, waste of materials, etc., to avoid waste, reduce battery cost, and benefit safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

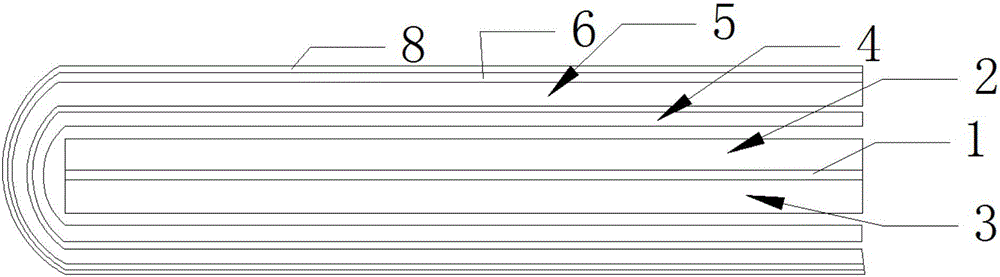

[0021] Embodiment 1: as figure 2 As shown, a sheet lithium-ion battery that effectively utilizes the battery space, the battery includes a positive electrode and a negative electrode folded in half, the positive electrode is sandwiched between the negative electrodes folded in half, and the positive electrode and the negative electrode are provided with Separator, both sides of the positive electrode are coated with active material, the inner side of the negative electrode folded in half is coated with active material, and the outer side of the negative electrode folded in half is coated with polymer insulating glue.

[0022] The thickness of the glue can be 2-50 microns thick according to the actual situation. The remaining procedures are conventional procedures. The polymer insulating glue can be PVDF, CMC, SBR, etc.

Embodiment 2

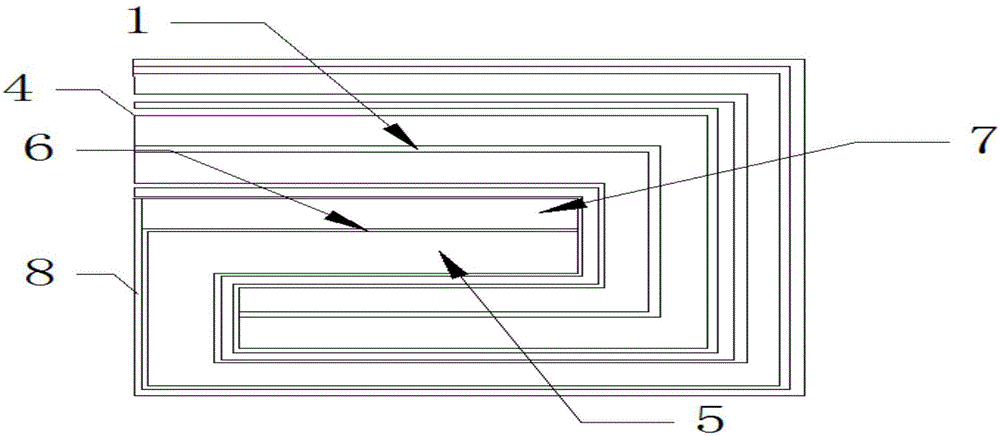

[0023] Embodiment 2: as image 3 As shown, a sheet lithium ion battery that effectively utilizes battery space, the battery includes a negative electrode that is divided into three equal parts by two creases, and a positive electrode that is folded in half, and the parts on both sides of the two creases are Folding to the same side of the middle part, one side of the positive electrode is aligned with one side of the negative electrode, the creases are aligned, and the other side of the positive electrode is inserted into the space formed by folding the other fold of the negative electrode, A diaphragm is provided between the positive electrode and the negative electrode, and the side of the negative electrode that is not in contact with the positive electrode is coated with polymer insulating glue.

[0024] The thickness of the glue can be 2-50 microns thick according to the actual situation. The remaining procedures are conventional procedures. The polymer insulating glue ...

Embodiment 3

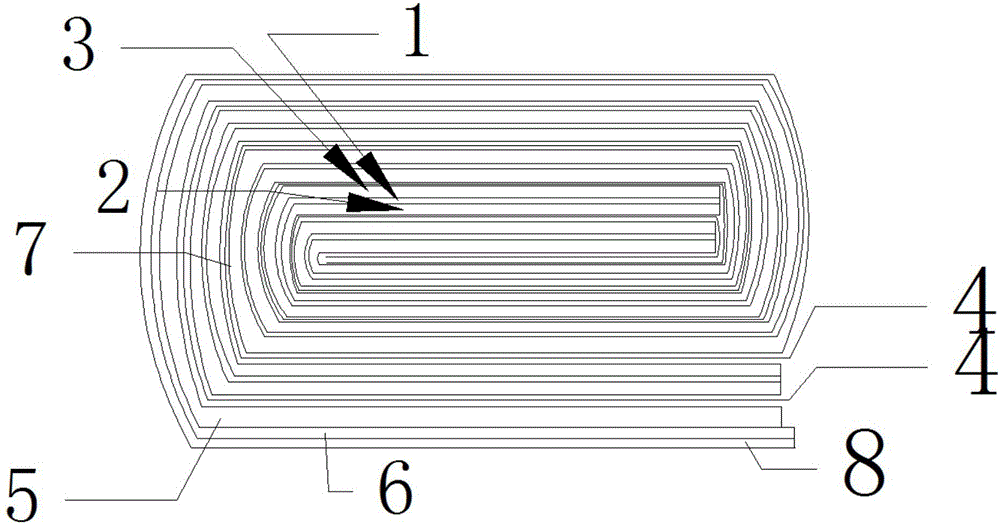

[0025] Embodiment 3: A thin-sheet lithium ion battery that effectively utilizes the battery space, the battery includes a positive electrode and a negative electrode, the positive electrode, the separator and the negative electrode are aligned from top to bottom, and the last part of the negative electrode after winding is There is no corresponding positive side on the outside (such as figure 1 Shown) coated with polymer insulating glue.

[0026] The thickness of the glue can be 2-50 microns thick according to the actual situation. The remaining procedures are conventional procedures. The polymer insulating glue can be PVDF, CMC, SBR, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com