Self-service washing machine

A washing machine and self-service technology, which is applied in the washing machine/washing machine for tableware, parts of the washing machine/rinsing machine for tableware, cleaning equipment, etc. , to achieve the effect of saving labor, reducing labor intensity and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

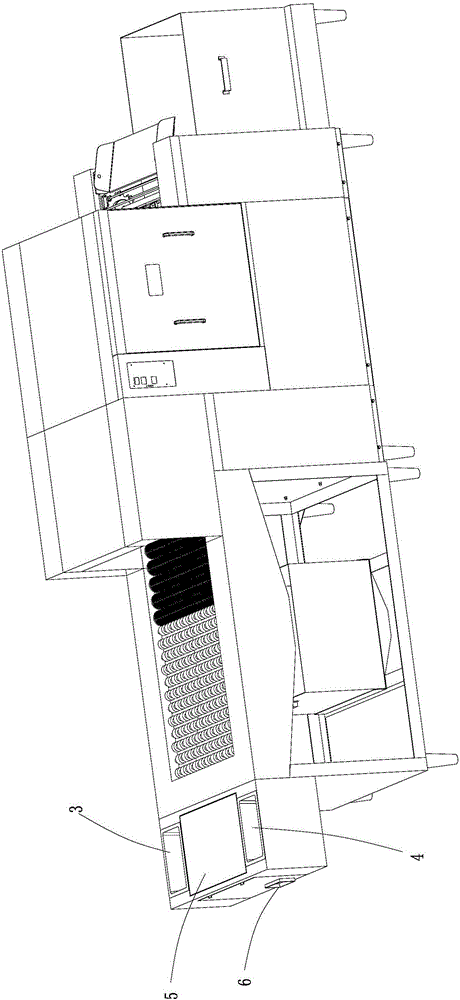

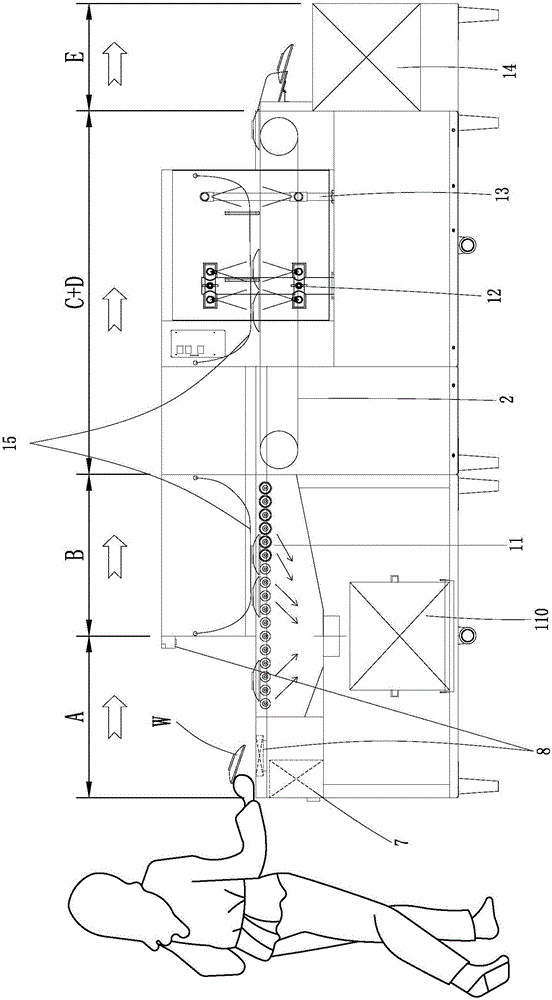

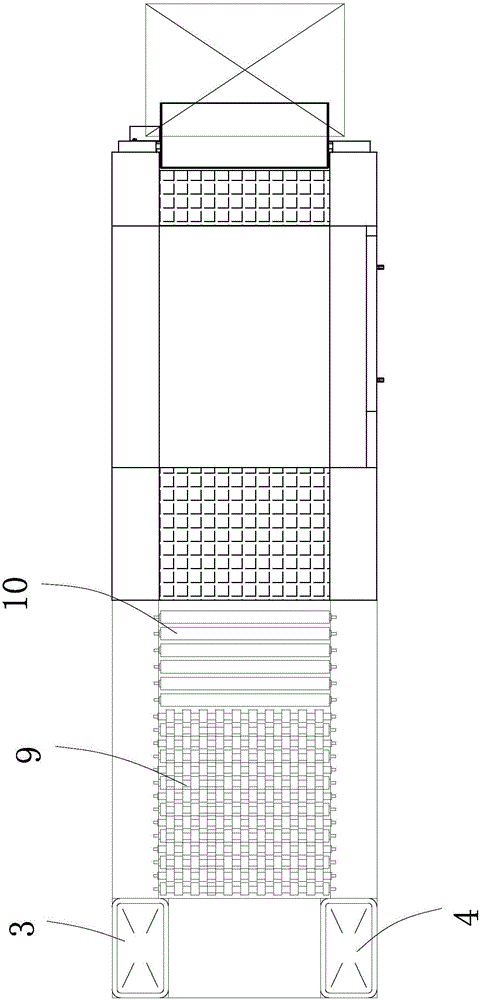

[0028] Example: see Figure 1 to Figure 10 , a kind of self-service washing machine, it comprises cabinet 1 and central control system 2, and cabinet 1 is provided with the conveying device of conveying tableware, is provided with putting area A, deslagging area B, washing area successively along the conveying direction of conveying device C. Cleaning area D and tableware collection area E; Leftovers area 3 and tableware collection bucket 4 are set on both sides of the front port of the drop-in area. A tableware sensor and a printer are arranged between the collection barrels 4, the tableware sensor and the printer are built in the glass cover 5, the printer is provided with a small ticket outlet 6, and a self-cleaning mechanism is provided in the cabinet 1, and the self-cleaning mechanism includes a self-cleaning mechanism. Pipeline 110 and some self-cleaning nozzle groups 111, self-cleaning nozzle groups are distributed in the delivery area, slag removal area, washing area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com