Novel multi-section annular oil-gas adsorption tank

An adsorption tank, ring-shaped technology, applied in the field of new multi-stage ring-shaped oil and gas adsorption tanks, can solve the problems of difficult loss of adsorption heat and rise in bed temperature, and achieve high oil and gas adsorption efficiency, high-efficiency adsorption, and strong activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

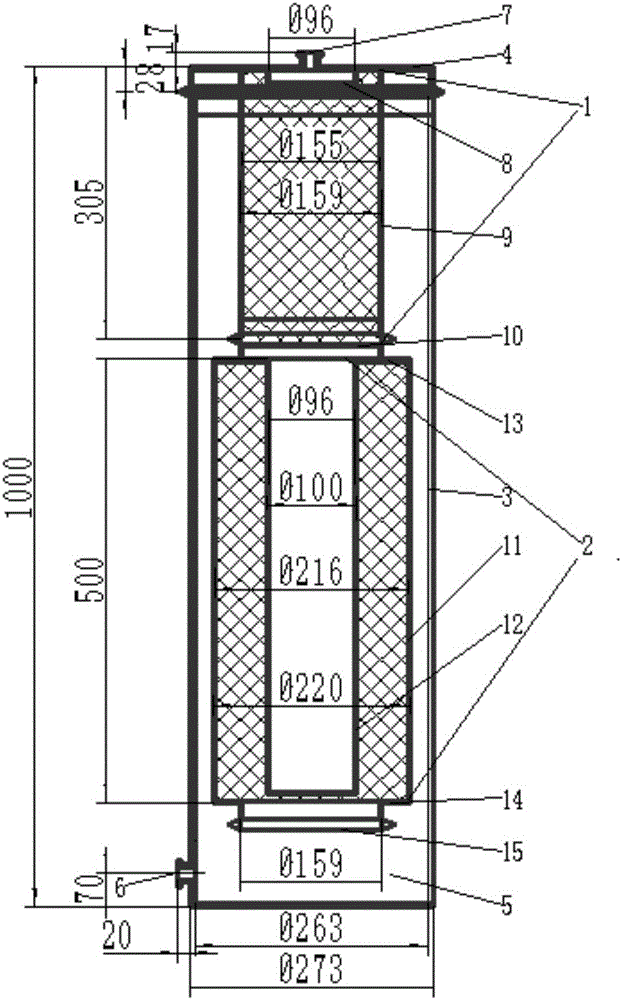

[0020] Such as figure 1 As shown, a new multi-section annular oil-gas adsorption tank includes an upper cylindrical adsorption area 1, a lower cylindrical adsorption area 2, an outer cylinder 3 and a top cover 4; Zone 5 and the buffer zone 5 are coaxially installed with the lower tubular adsorption zone 2 and the upper columnar adsorption zone 1 in turn, and the top cover 4 is set on the top of the outer cylinder 3 to form a closed tank; the buffer zone 5 of the outer cylinder 3 is provided with an inlet The air outlet 6 and the center of the top cover 4 are provided with an air outlet 7; the bottom of the air outlet 7 and the columnar adsorption area 1 of the upper section are provided with a multi-layer filter net 8. After the assembly is completed, the upper cylindrical adsorption area 1 is close to the multi-layer filter 8 to prevent the filtered gas from bringing the activated carbon particles in the tank into the air; oil and gas enter the tank through the air inlet 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com