A Forging Forming Process of Straight Oil Groove on Spherical Surface of Differential Planetary Gear

A planetary gear and forming processing technology, which is applied in the field of gear forging, can solve the problems of low production efficiency and processing quality that cannot meet the requirements, and achieve the effects of improving product production efficiency, reducing production cost input, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

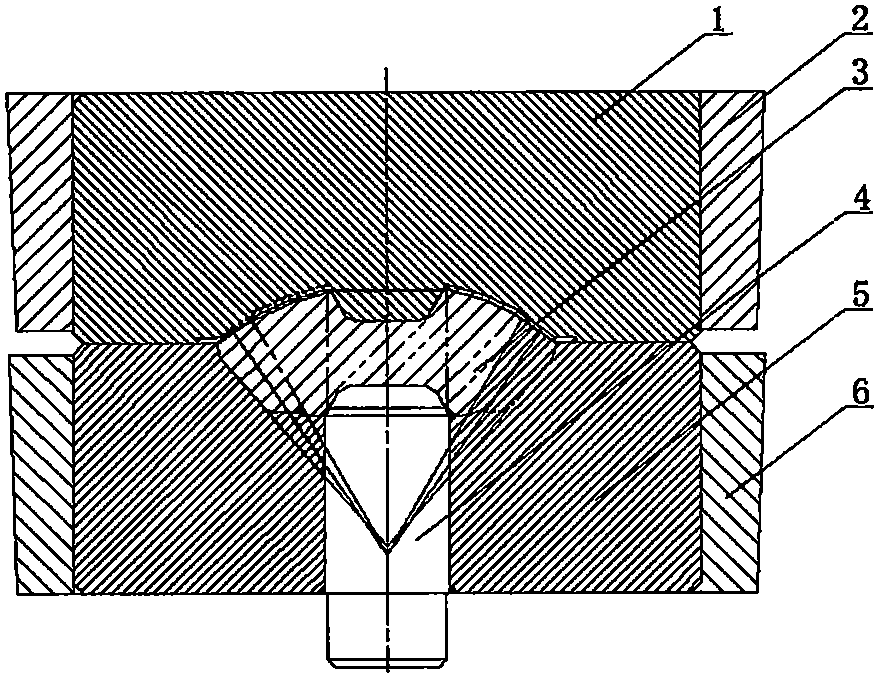

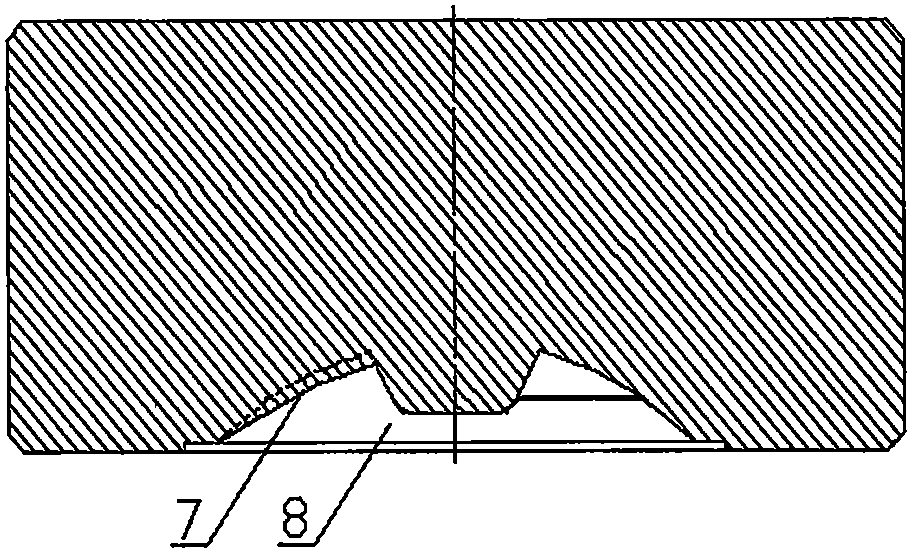

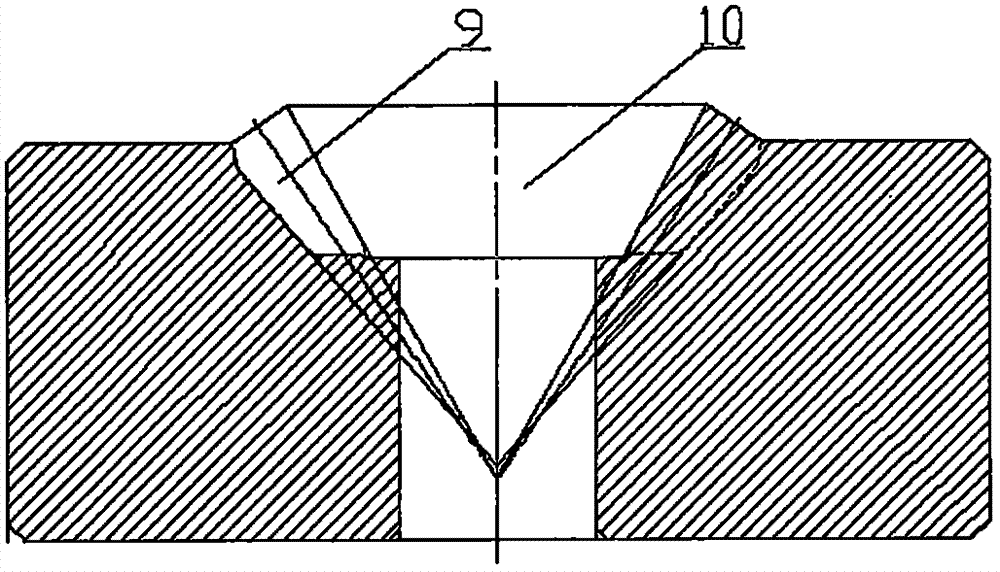

[0017] Specific embodiment 1: In order to solve the problem that the production efficiency of the straight oil groove added on the spherical surface of the planetary gear is low and the processing quality cannot meet the requirements in the processing process, the present invention provides a forging of the straight oil groove on the spherical surface of the differential planetary gear The forming process, the technical scheme of which is as follows: a forging forming process of straight oil grooves on the spherical surface of the differential planetary gear, comprising the following steps:

[0018] Step 1. Three-dimensional modeling. First, use SolidWorks three-dimensional software to perform three-dimensional modeling on the part drawing to generate a cold three-dimensional solid part. Then, in combination with forging conditions and machining conditions, reserve a machining allowance of 1-1.5mm on the spherical surface. , refer to the linear expansion coefficient of the forg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com