A multi-station assembling machine for a fire retardant ring

A fire-stop ring and assembly machine technology, which is applied in assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of easy loosening, durability, low efficiency, and more labor, and achieve accurate and reliable positioning, high stability, and high stability. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

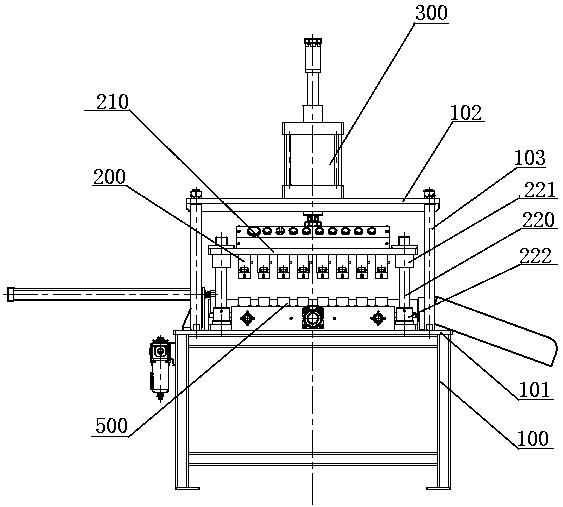

[0034] Such as figure 1 As shown, a multi-station assembly machine for fire arresting rings includes a frame 100, the frame 100 includes a bottom plate 101, four columns 103 are fixed on the bottom plate 101, and a top plate is provided on the top of the columns 103 102. The top plate 102 is provided with a pressurizing device 300, the pressurizing device 300 is a pressurized cylinder, the piston rod of which penetrates the top plate 102 and is drivingly connected with the housing positioning device 200, and a core material positioning device is provided below the housing positioning device 200. The device 500 and the core material positioning device 500 are fixed on the bottom plate 101 .

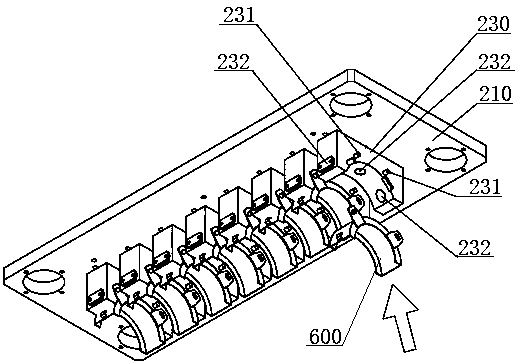

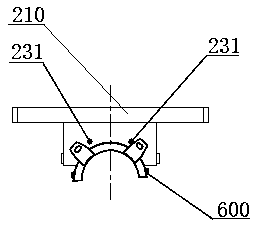

[0035] Such as figure 2 , 3 As shown in and 4, the shell positioning device 200 includes a plurality of mounting seats 230 adapted to the shape of the fire arresting ring shell, and the mounting seats 230 are provided with a fixing mechanism that can be used to fix the fire arresting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com