Movement control method for six-shaft industrial robot of specific structure

A technology of industrial robots and motion control, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of complex calculation process, inability to calculate inverse solutions, and inability to eliminate elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

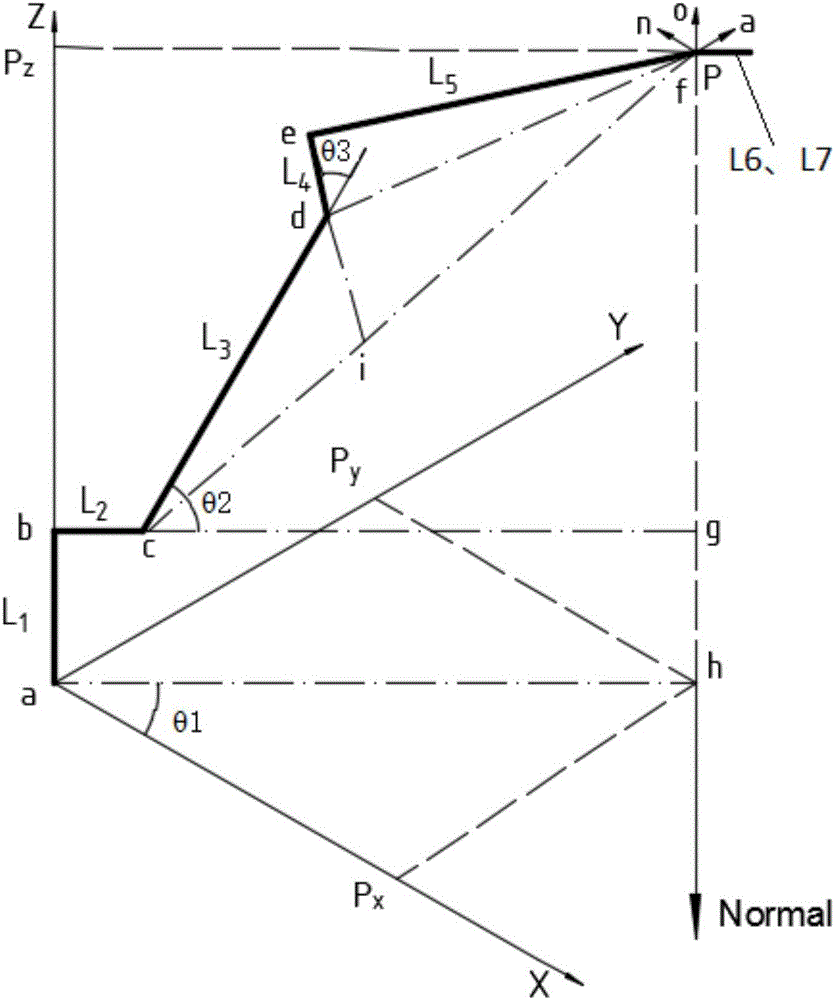

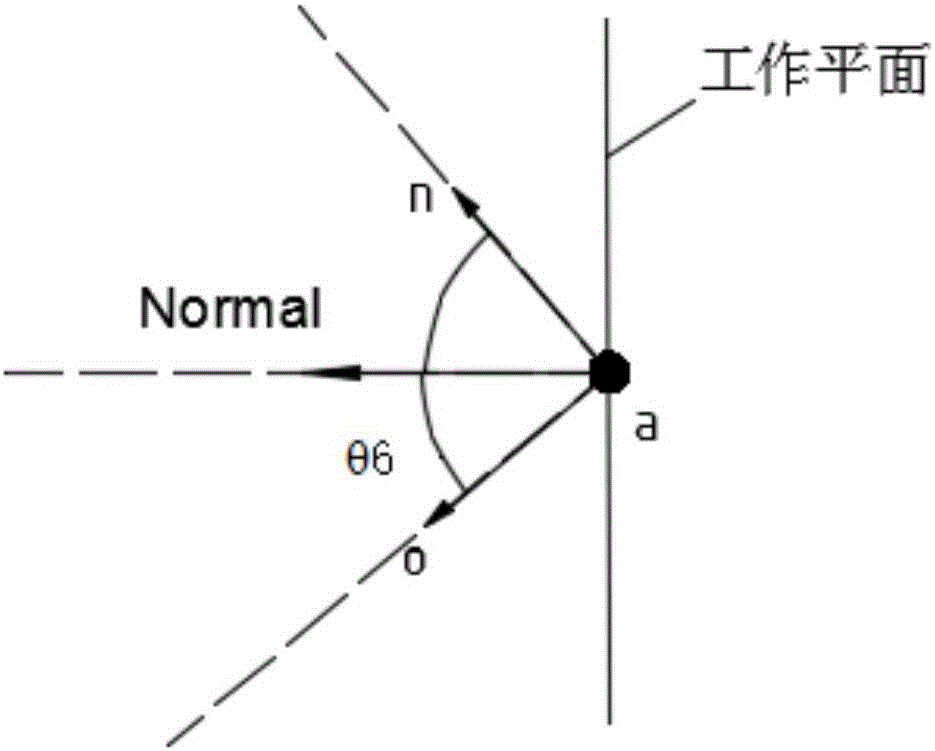

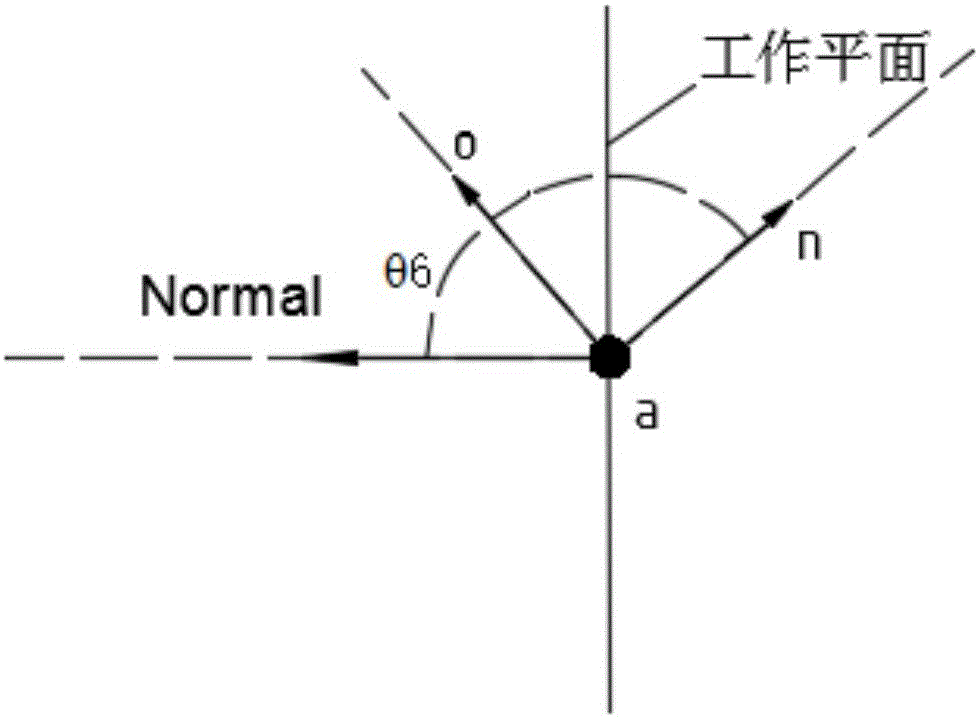

[0054] The invention provides a motion control method for a six-axis industrial robot with a specific configuration, comprising the following steps:

[0055] S1. Establish the connecting rod coordinate system of the industrial robot, and obtain the geometric relationship between the seven rods and the six axes of the industrial robot;

[0056] S2. After obtaining the G command file corresponding to the industrial robot, read the target motion position of the industrial robot;

[0057] S3. According to the target motion position and the geometric relationship of the industrial robot, sequentially calculate the joint angles of the six axes of the industrial robot;

[0058] S4. After converting the calculated six joint angles into the number of motion pulses corresponding to each axis, send them to the driver of the industrial robot;

[0059] S5. The driver sequentially drives the corresponding motors to drive the corresponding axes to move according to the number of motion puls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com