Self-lubricating floating sandwich channel type electrified railway power transmission system

A power transmission system and self-lubricating technology, which is applied to current collectors, electric vehicles, power rails, etc., to achieve the effects of prolonging service life, avoiding impact phenomena, and ensuring driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

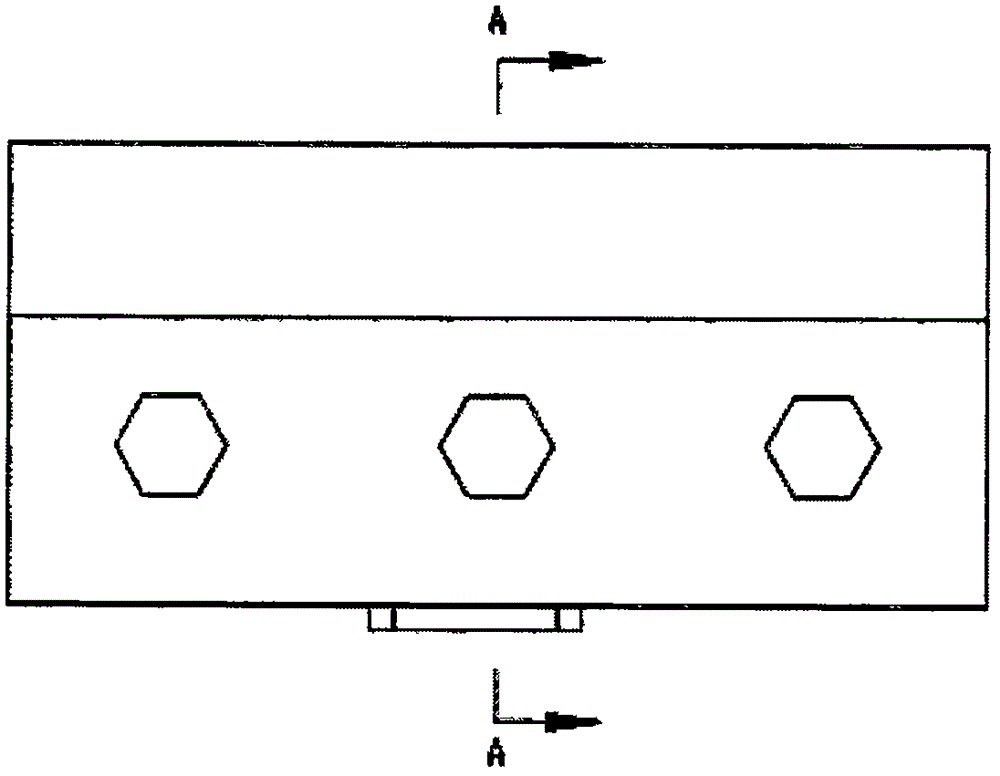

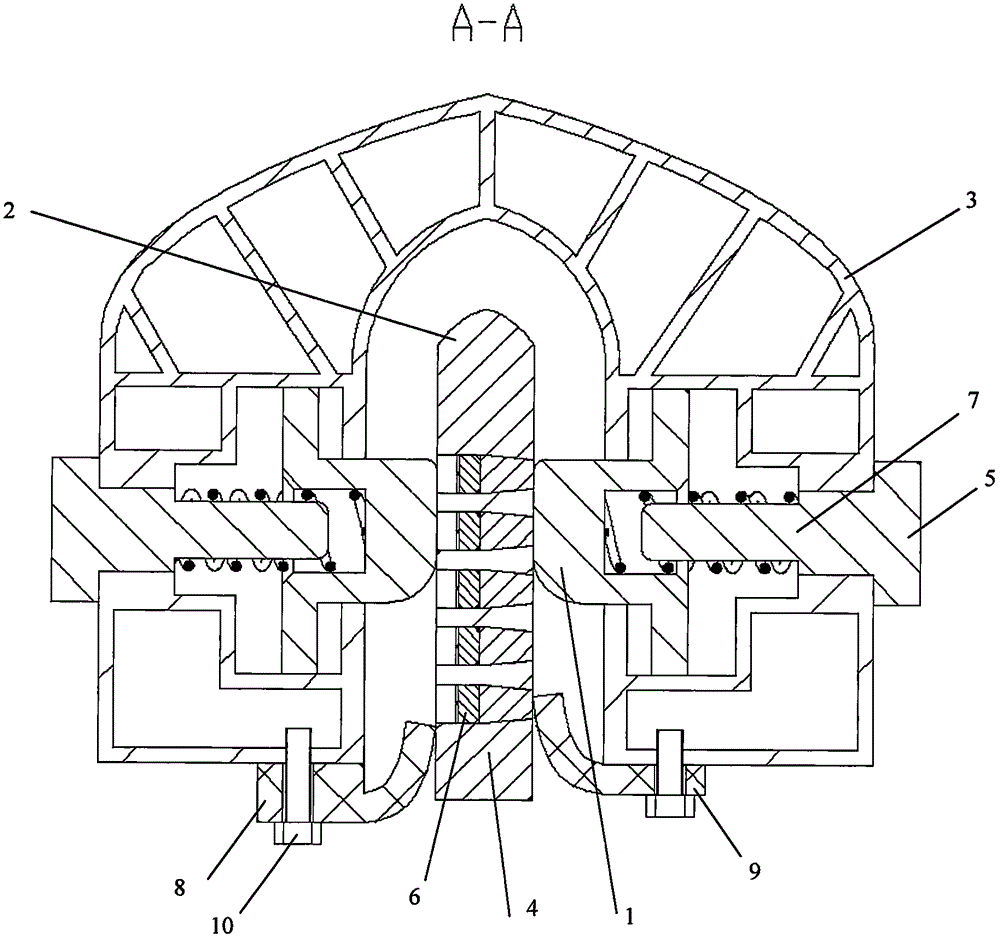

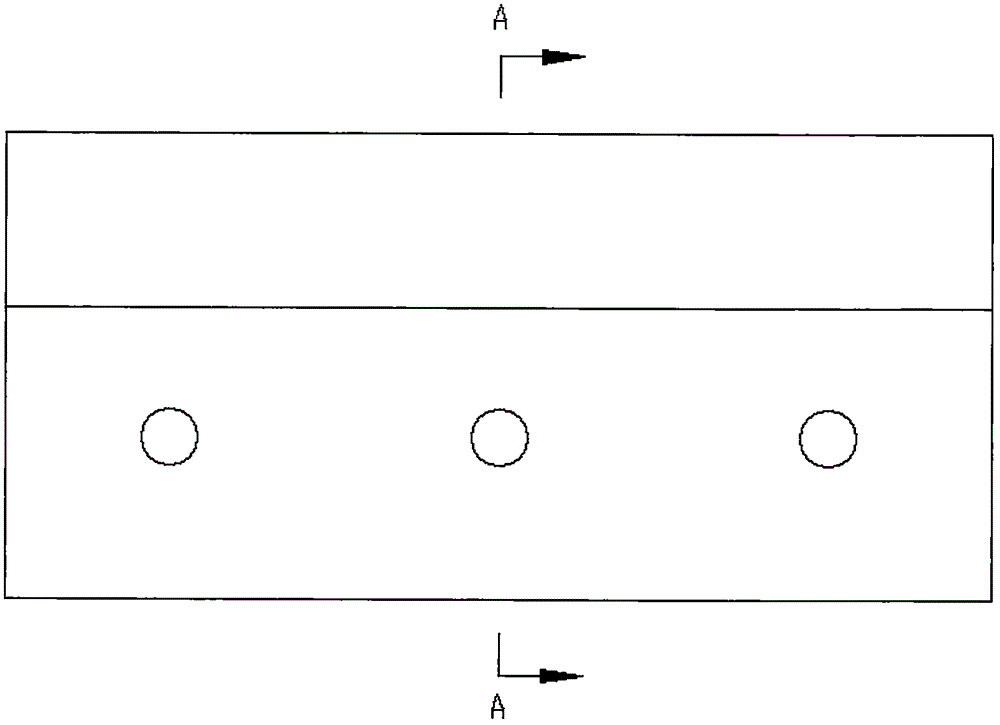

[0028] A self-lubricating floating sandwich channel rail transit power transmission system, such as image 3 and Figure 4 As shown, its three-dimensional support shield 3 is made of insulating material, has a plurality of slotted hole structures in the middle, and has spring fixing holes 11 on its side. The self-lubricating floating channel 1 is made of conductors such as copper and aluminum, and is located One of the slots in cover 3, such as figure 1 and figure 2 As shown, the lower edge 21 of the floating channel is in contact with the three-dimensional support shield 3 slot holes and is supported by it. There is a floating channel spring hole 20 on the side of the self-lubricating floating channel 1. One end of the spring 7 is located in the spring hole 20 of the floating channel, and the other end Withstood against the spring plug 5, the spring plug 5 and the spring fixing hole 11 are threaded or glued or tightly connected and fastened. The self-lubricating conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com