A storage system optimization scheduling method combining shuttle cars and elevators

A technology for optimizing scheduling and warehousing systems, applied to transportation, packaging, storage devices, etc., to achieve the effects of saving energy, optimizing scheduling, and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the drawings and embodiments.

[0026] The present invention provides a hybrid optimal scheduling method for shuttle bus and elevator, which is specifically implemented according to the following steps:

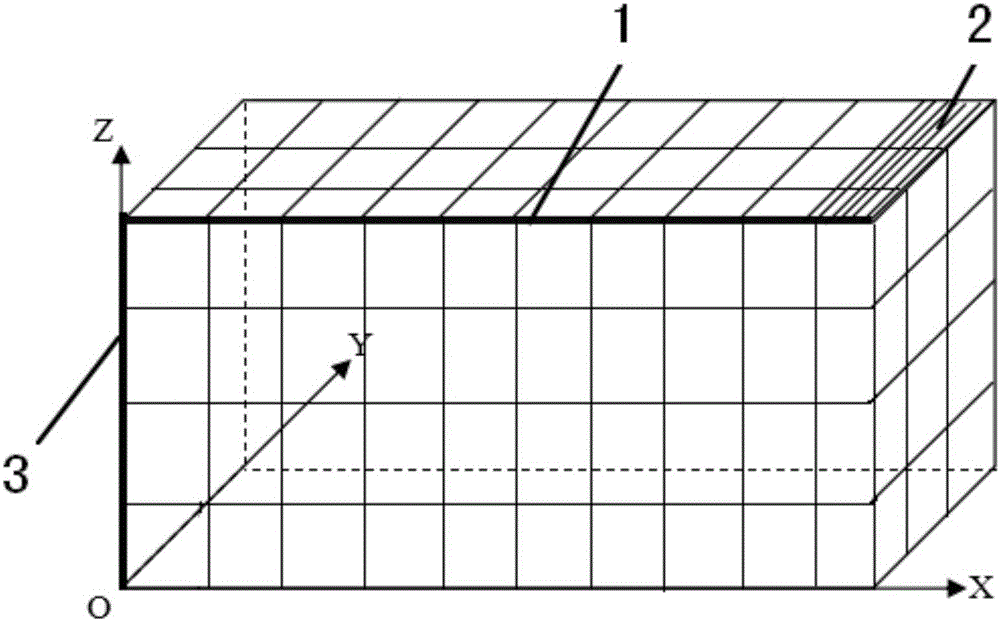

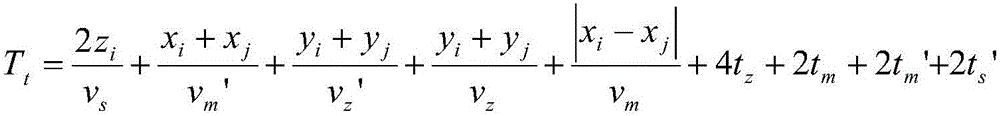

[0027] Step 1 Establish a reasonable mathematical model for the dispatching situation of a lift with a set of shuttle vehicles (1:1 type);

[0028] 1.1 Analyze and research the fully automatic three-dimensional warehouse of shuttle bus, and formulate the rules of goods storage

[0029] See figure 1 , The shuttle car fully automatic three-dimensional warehouse includes: shuttle car (composed of child car and mother car), mother car walking track (lane), child car walking track (shelf row), shuttle rack, pallet vertical lifting system ( Lift), pallet conveying system, CMS equipment control system, WMS warehouse management system. Convert the actual shuttle car into a fully automatic three-dimensional w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com