Mechanical arm

A technology of mechanical arms and moving arms, applied in the direction of manipulators, conveyors, conveyor objects, etc., can solve the problems of poor static elimination ability, abnormal vacuum, difficult selection of suction nozzles on the arm, etc., to achieve easy suction and eliminate static electricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

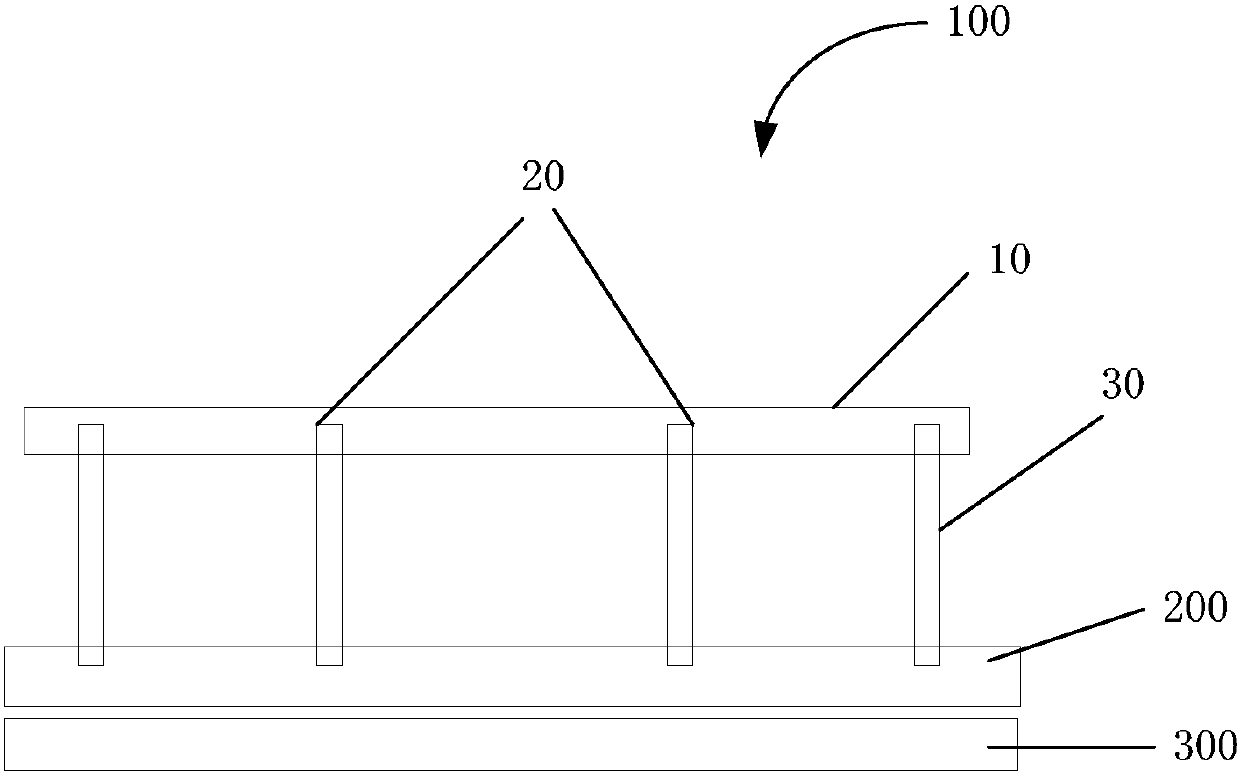

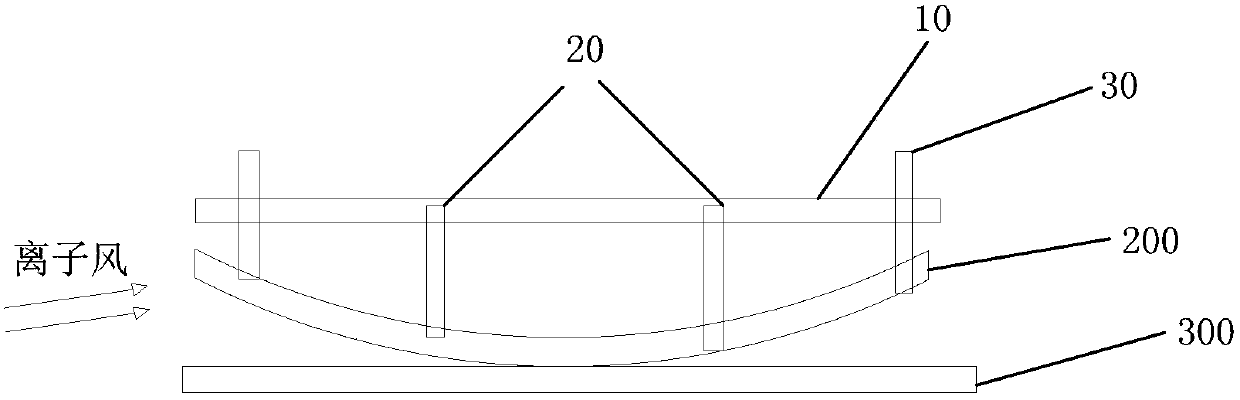

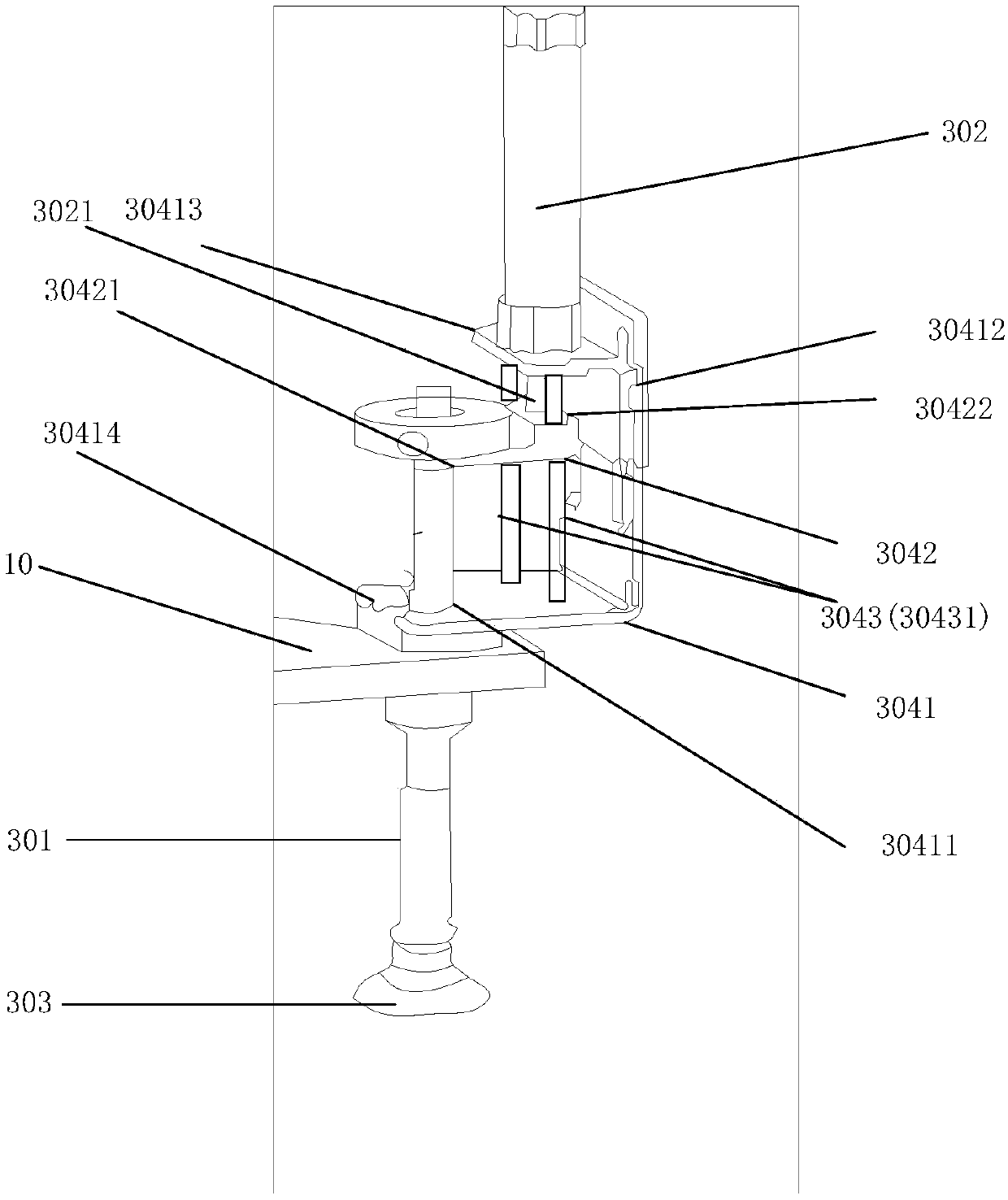

[0028] refer to figure 1 with figure 2 , figure 1 with figure 2 is a structural schematic diagram of an embodiment of the robot arm of the present invention, wherein, figure 1 is a schematic diagram of the robot arm touching the first object and the panel, figure 2 is a schematic diagram of the robotic arm picking up the edge of the first object.

[0029] The robot arm 100 includes: a moving arm 10 , a first type of suction device 20 and a second type of suction device 30 .

[0030] The moving arm 10 is arranged horizontally, and is used for moving horizontally or vertically to move away from or approach the first object 200 to be adsorbed, and the first object 200 is in close contact with the panel 300 .

[0031] In practical applications, the mobile arm 10 may be a flat plate arranged horizontally, or a frame arranged horizontally, or other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com