Palletizer for feed production line and production method thereof

A technology of production line and palletizer, which is applied in the field of feed production line to achieve great economic benefits, good effect and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

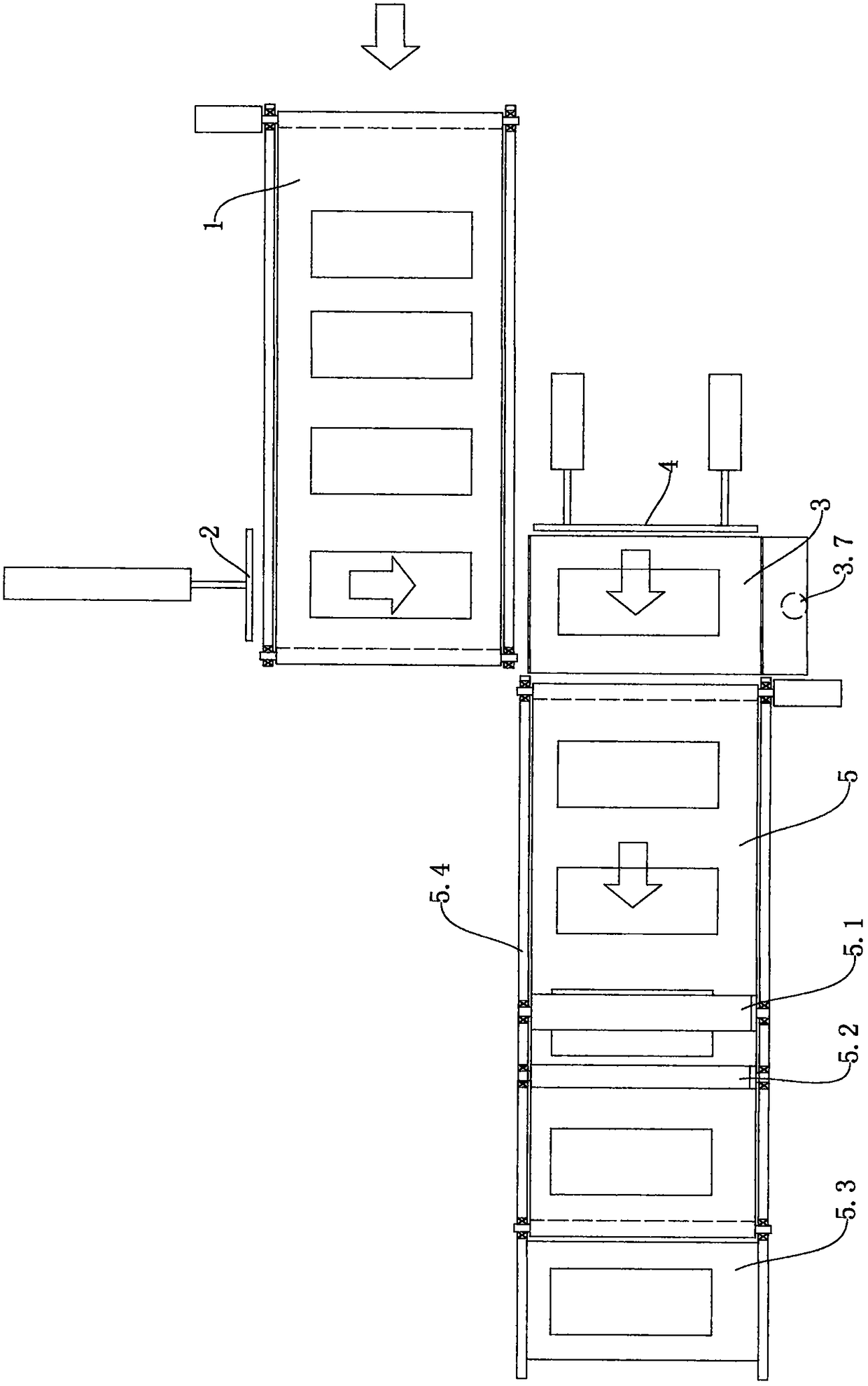

[0033] Example: such as figure 1 Shown, a kind of palletizer of feed production line, comprises the first conveyor belt 1, the first pusher 2, leveling device 3, the second pusher 4 and the second conveyor belt 5, and described first pusher 2 is arranged on the described One side of the first conveyor belt 1 pushes the feed package conveyed on the first conveyor belt 1 into the leveling device 3 on the other side of the first conveyor belt 1; the second pusher 4 is arranged on the One side of the leveling device 3, pushes the feed packs in the leveling device 3 that have been leveled by tilting and flattening to the second conveyor belt 5 on the other side of the leveling device 3.

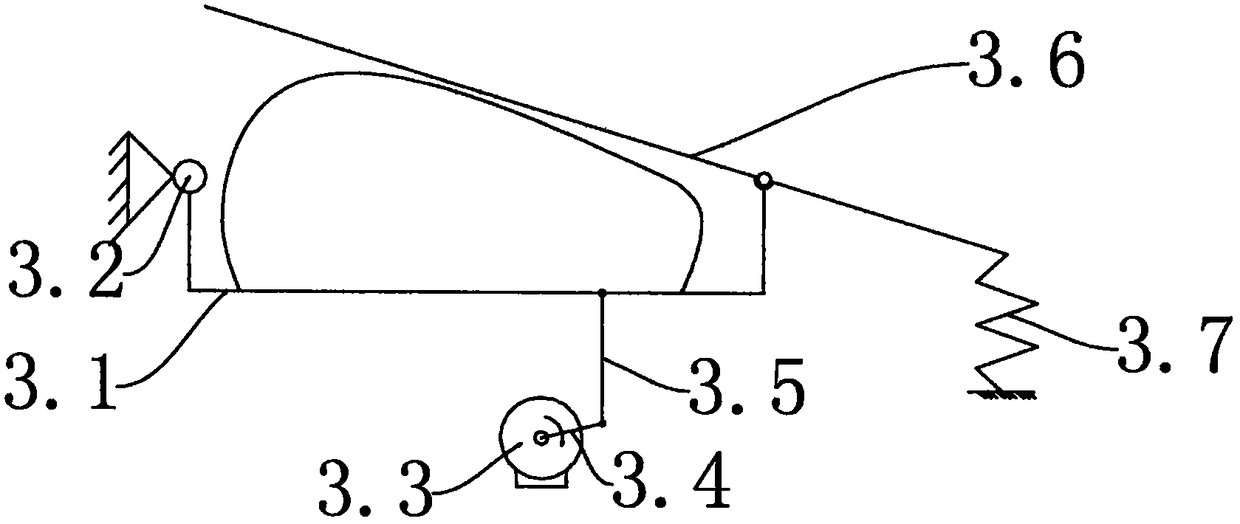

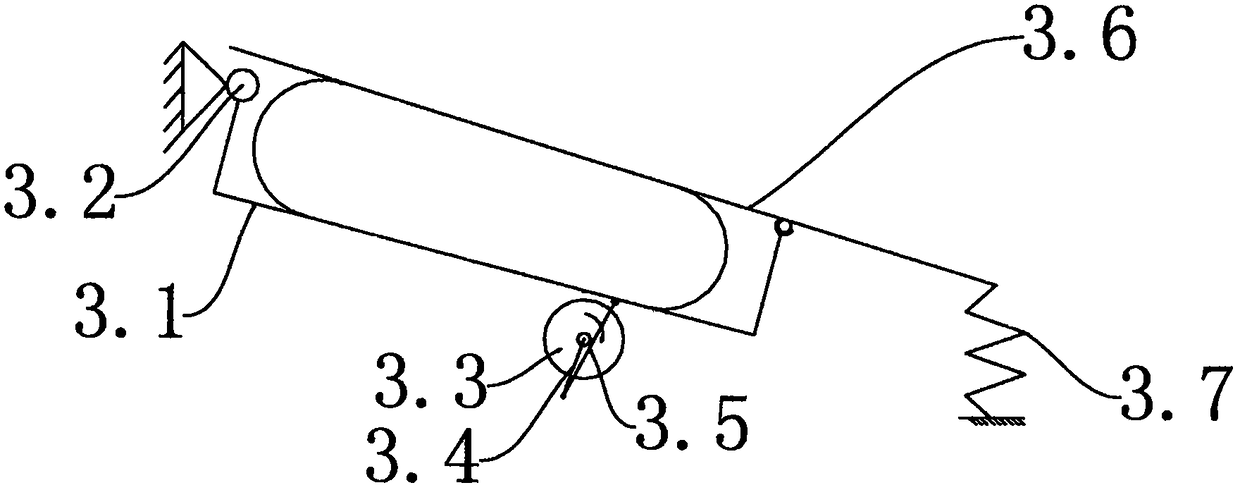

[0034] Such as Figure 2 to Figure 4 As shown, the leveling device 3 includes a lower pressure groove 3.1, a first pivot shaft 3.2, a reduction motor 3.3, a rocker 3.4, a connecting rod 3.5, an upper pressing plate 3.6 and a spring 3.7, and the lower pressure groove 3.1 is an upward opening. Cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com