A traction system for elevators

A technology of traction system and elevator, which is applied in the field of traction system, can solve the problems of high output power and energy consumption, large traction force, and limited car load, so as to reduce load and energy consumption, reduce weight difference, The effect of increasing the load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

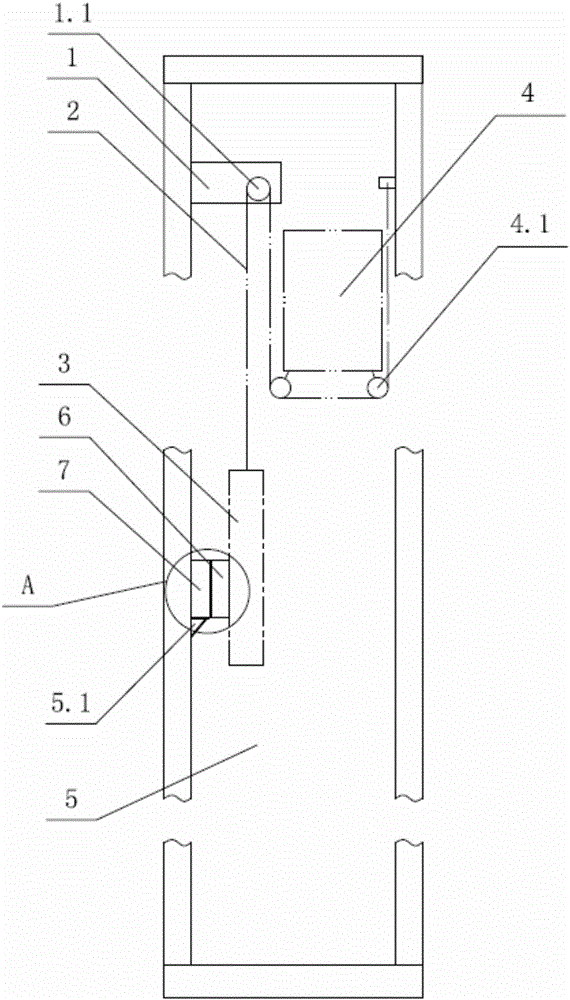

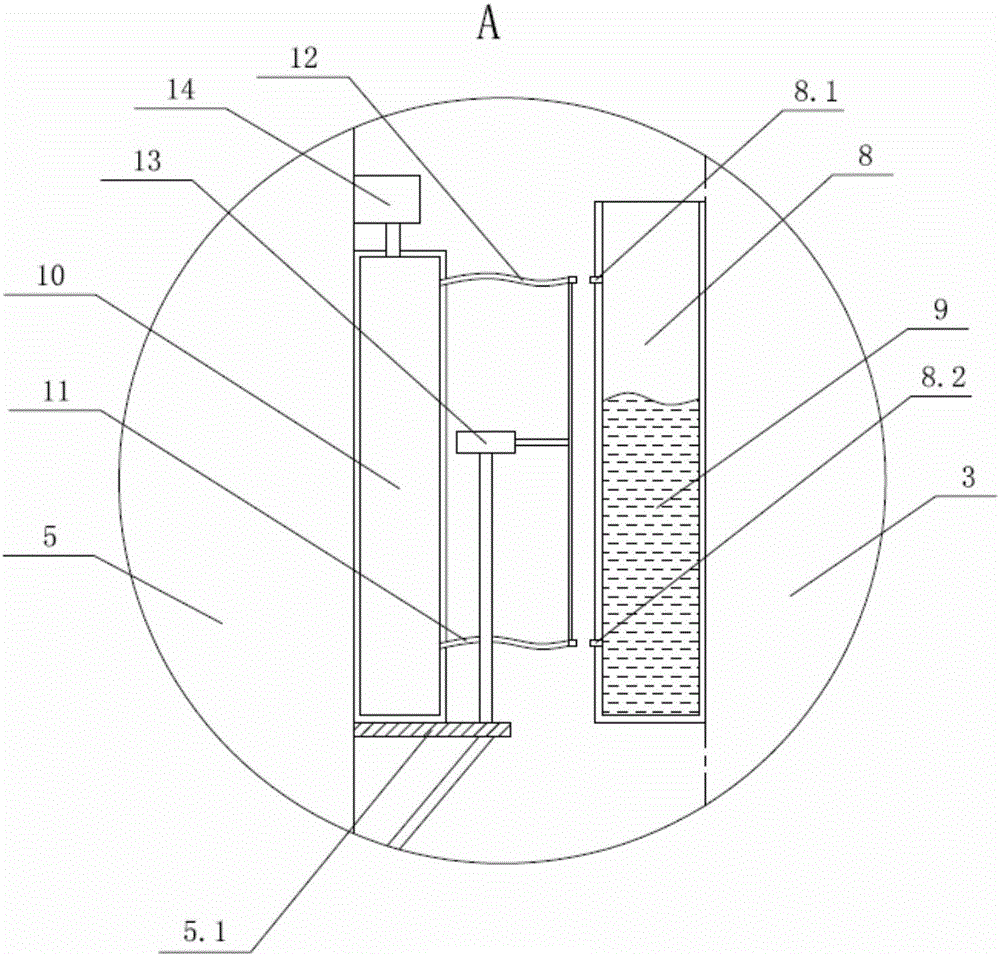

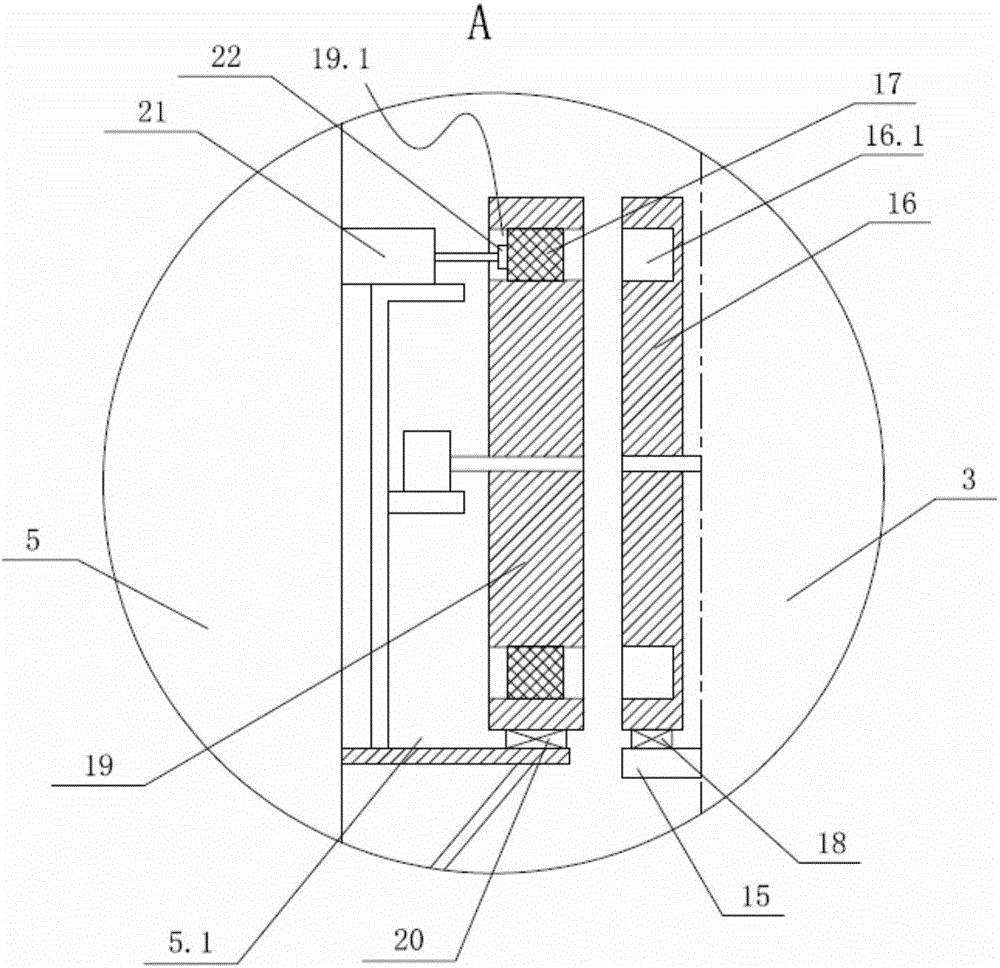

[0020] The invention provides a traction system for an elevator, which includes a traction machine 1 installed in the hoistway, a traction wire rope 2 and a counterweight 3 arranged under the traction machine 1, and one end of the traction wire rope 2 It is fixed to the inner wall of the hoistway 5, and the other end of the traction wire rope 2 encircles the guide wheel 4.1 at the bottom of the car 4 and the driving wheel 1.1 on the traction machine 1 in sequence along its own length, and is fixed with the counterweight 3. Its features That is: the counterweight 3 is provided with a counterweight assembly 6, and the hoistway 5 is provided with a weight adjustment mechanism 7 for changing the weight of the counterweight assembly 6 when the car 4 is stationary. The outer peripheral wall of the guide wheel 4.1 is provided with an annular groove 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com