Water purification machine capable of automatically flushing filter element and pipelines and control method thereof

An automatic flushing and water purifier technology, applied in chemical instruments and methods, filtration treatment, water/sewage treatment, etc., can solve problems such as failure to meet high water sanitation requirements, high after-sales service costs, and post-filter pollution. , to reduce the cost of after-sales service, ensure the hygiene of drinking water, and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A water purifier that can automatically flush the filter element and pipeline, with automatic flushing function, when it is used for the first time or other automatic flushing is required, the water inlet pipeline of the water purifier is opened, the water outlet pipeline of the water purifier is closed, and the water purifier The purified water prepared by the machine is discharged from the waste water pipe. By closing the water outlet pipeline of the water purifier, the tap water entering the water purifier first cleans the filter element and the pipeline, and the cleaned waste water is drained from the waste water pipeline.

[0035] Specifically, the opening or closing of the water inlet pipeline of the water purifier is realized through the water inlet valve; the opening or closing of the water outlet pipeline of the water purifier is realized through the water outlet valve.

[0036] When performing automatic flushing, the purified water prepared by the water purifi...

Embodiment 2

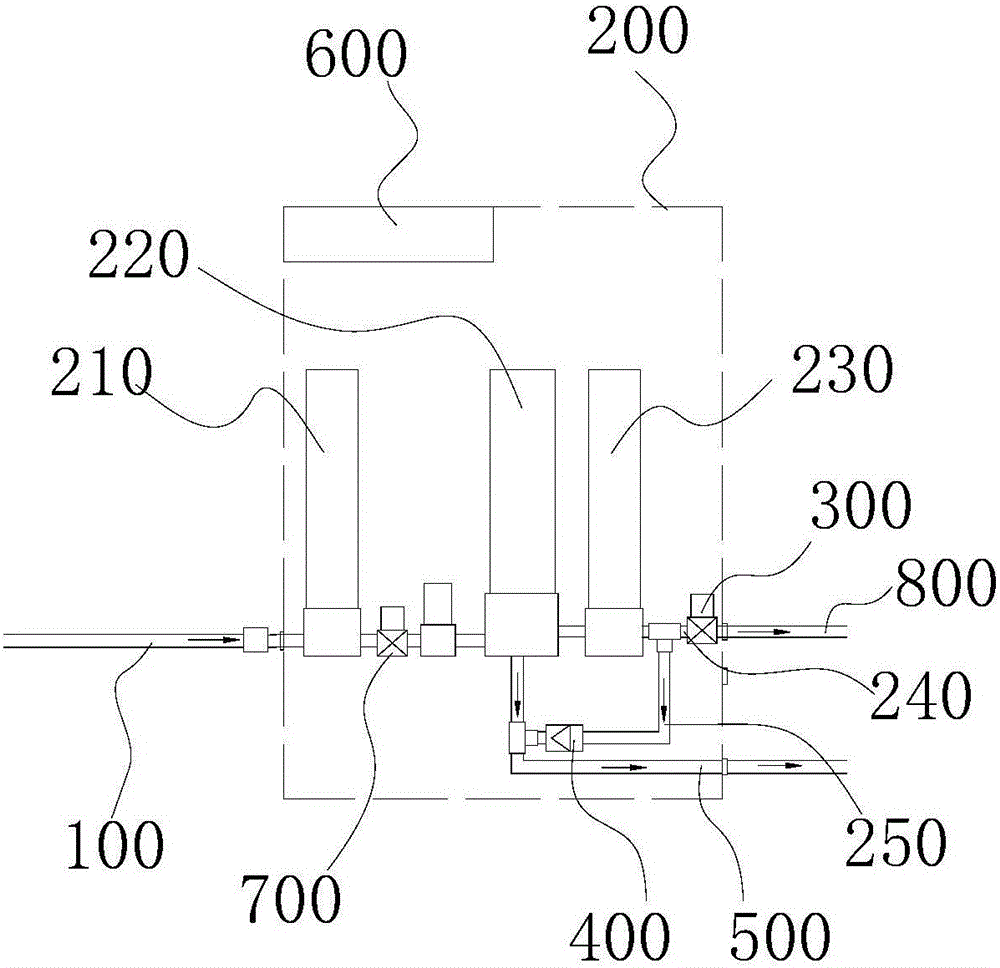

[0041] A water purifier that can automatically flush filter elements and pipelines, such as figure 1 As shown, a filter system 200, a water outlet valve 300 and a one-way valve 400 are provided. The water inlet of the filtration system 200 is in sealing communication with the tap water supply pipe 100, the purified water outlet of the filtration system 200 is divided into a first water pipe 240 and a second water pipe 250, and the first water pipe 240 is in sealing communication with the water inlet of the water outlet valve 300, The water outlet of the water outlet valve 300 is in sealing communication with the water outlet pipeline 800 , the second water pipe 250 is in communication with the water inlet of the one-way valve 400 , and the water outlet of the one-way valve 400 is in sealing communication with the waste water pipeline 500 through the pipeline.

[0042] The one-way valve 400 is a one-way valve 400 in which water can only enter from the water inlet of the one-way...

Embodiment 3

[0055] Provide a control method for the water purifier that can automatically flush the filter element and pipeline in Embodiment 1, specifically: when the water purifier is cleaning the filter element and pipeline, control the water outlet valve 300 to close and the booster pump to open, The purified water produced by the filtration system 200 enters the water inlet of the one-way valve 400 through the second water pipe 250, and is discharged from the water outlet of the one-way valve 400 by the waste water pipeline 500; after the water inlet machine is cleaned, the booster pump stop working.

[0056] When the water purifier is running water, the water outlet valve 300 is controlled to be turned on, the booster pump is turned on, and the purified water produced by the filter system 200 passes through the first water pipe 240 through the water outlet valve 300 , and then is discharged from the water outlet pipeline 800 .

[0057] Preferably, when the above control method is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com