A rotary jacking waterproof workbench

A technology of worktable and rotary table, which is applied in the field of rotary jacking waterproof workbench, can solve the problems of large volume, achieve the effects of small installation volume, reduced product volume, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

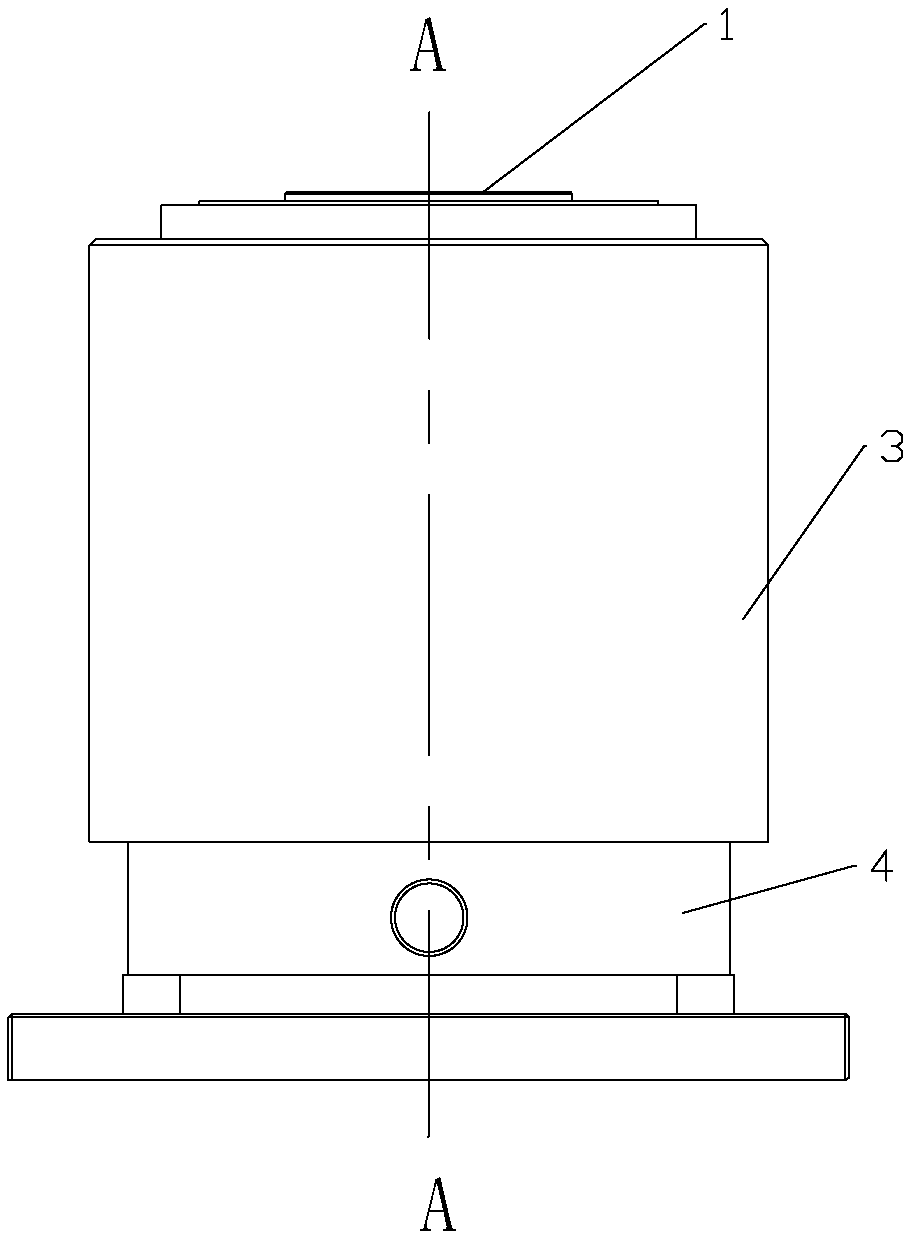

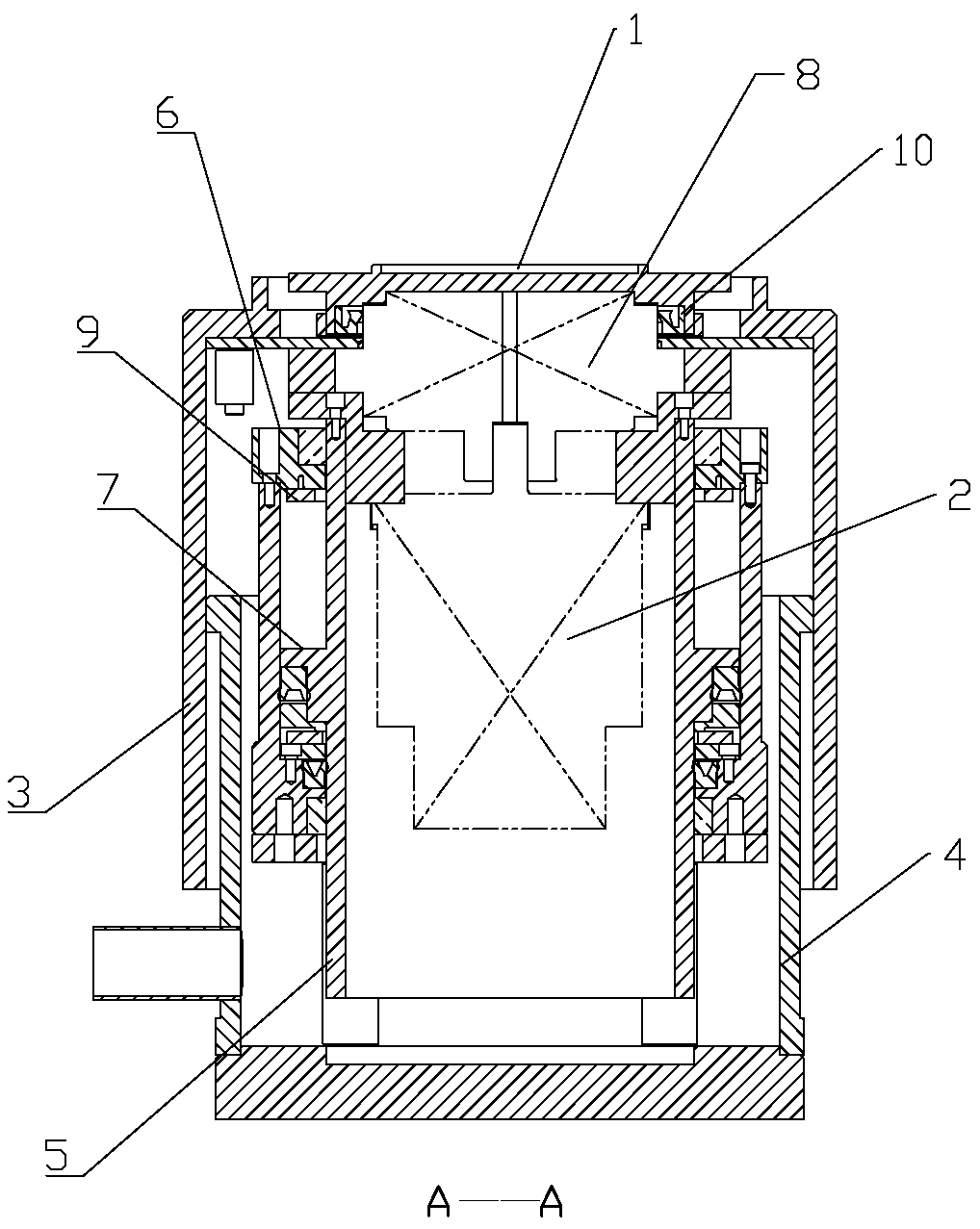

[0038] One of the embodiments of a rotary jacking waterproof workbench of the present invention, such as figure 1 and figure 2 As shown, wherein, including a jacking cylinder, a rotary table 1, a rotating mechanism and a casing 3, the casing 3 is arranged on the outside of the jacking cylinder, and the jacking cylinder is provided with a cylinder barrel 4, a cylinder upper cover 6 and a piston 5 and its The limit block 7, the cylinder upper cover 6 is sealed and fixedly connected with the upper end of the cylinder barrel 4, the lower end surface of the cylinder upper cover 6, the inner surface of the cylinder barrel 4, the outer surface of the piston 5 and the upper end surface of the limit block 7 form an annular air cavity, The piston 5 is provided with a hollow cavity, and the rotary motor 2 is built into the hollow cavity of the piston 5 and is fixedly connected with the piston 5 through its stator. The output shaft of the rotary motor 2 is pivotally connected with the ro...

Embodiment 2

[0042] One of the embodiments of a rotary jacking waterproof workbench of the present invention, such as figure 1 and figure 2 As shown, the main technical solution of this embodiment 2 is basically the same as that of embodiment 1, and the features not explained in this embodiment 2 are explained in embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that: a reduction device 8 is provided between the rotary motor 2 and the rotary table 1 , and the rotary motor 2 is pivotally connected to the rotary table 1 through the reduction device 8 . By adding the deceleration device 8, the output torque of the motor can be increased, the transfer speed can be controlled, and the selection range of the motor can be increased.

[0043] Specifically, the reduction device 8 may be a gear reduction device.

[0044] More specifically, the reduction device 8 may be a planetary gear reduction device.

Embodiment 3

[0046] One of the embodiments of a rotary jacking waterproof workbench of the present invention, such as figure 1 and figure 2As shown, the main technical solution of this embodiment 3 is basically the same as that of embodiment 1 or embodiment 2, and the features that are not explained in this embodiment 3 adopt the explanations in embodiment 1 or embodiment 2, and are not repeated here to repeat. The difference between this embodiment and embodiment 1 or embodiment 2 is that the jacking cylinder is set as a double-acting cylinder with two air cavities, and the other air cavity is set as the top surface of the cylinder bottom, the inner surface of the cylinder barrel 4 and the piston 5 The outer surface and the annular air cavity formed by the lower end surface of the limit block 7, or set as the upper end surface of the cylinder bottom, the inner surface of the cylinder barrel 4 and the outer surface of the lower end surface of the piston 5 and its lower end surface or the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com