Environment-friendly 3D printing consumable and production process thereof

A 3D printing and production process technology, applied in the 3D field, can solve problems such as strength to be improved, not enough environmental protection, etc., to achieve the effect of convenience, high environmental protection strength, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

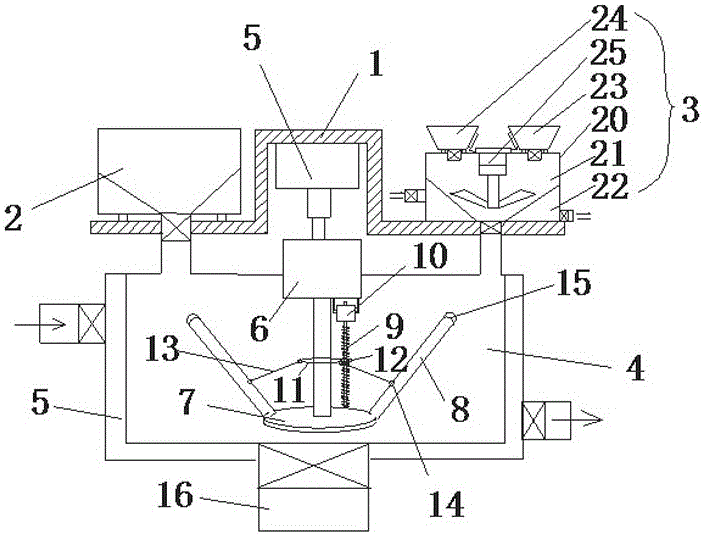

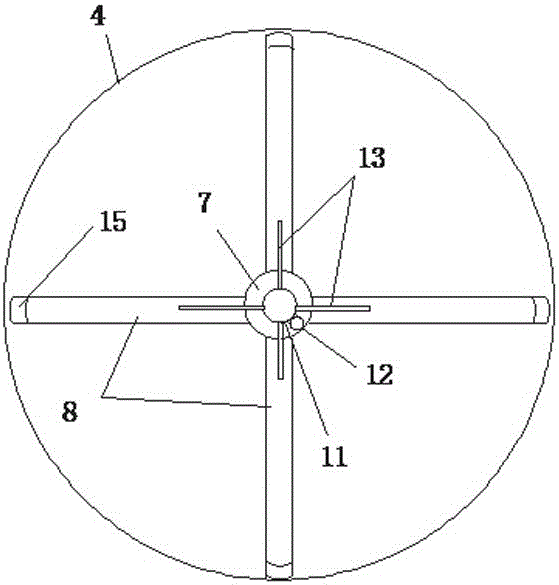

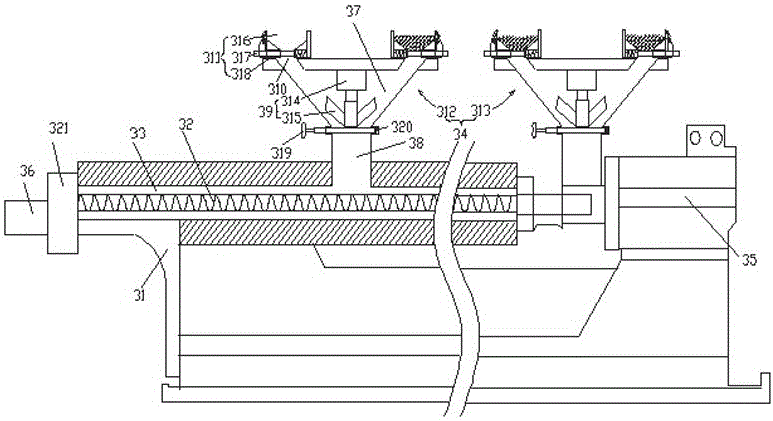

Method used

Image

Examples

Embodiment 1

[0045] An environmentally friendly 3D printing consumable, which is compounded with diatomite, and the weight percentage of the diatomite is 20%; the above-mentioned 3D printing consumable is composed of nylon 610, diatomite and a coupling agent; wherein the coupling The weight ratio of agent to diatomaceous earth is 3:1000, and the rest is nylon 610.

[0046] The production process of the above consumables is carried out as follows:

[0047] 1) Vacuum dry nylon 610 at a temperature of 90-110 degrees for 11-12 hours;

[0048] 2) Wrap the dried nylon for use;

[0049] 3) Use a 1000-mesh screen to screen the first-grade diatomite;

[0050] 4) Mix absolute alcohol and KH560 coupling agent according to the weight ratio of 97:3 to form a mixed solution;

[0051] 5) Stir and mix the screened diatomite and the mixed solution at high temperature according to the weight ratio of 100:9, and control the temperature between 130-140 degrees to remove alcohol;

[0052]6) Put the mixture...

Embodiment 2

[0058] An environmentally friendly 3D printing consumable, which is compounded with diatomite, and the weight percentage of the diatomite is 30%; the above-mentioned 3D printing consumable is composed of nylon 612, diatomite and a coupling agent; wherein the coupling The weight ratio of agent to diatomaceous earth is 2:1000, and the rest is nylon 612.

[0059] The production process of the above consumables is carried out as follows:

[0060] 1) Vacuum dry nylon 612 at a temperature of 110-130 degrees for 12-13 hours;

[0061] 2) Wrap the dried nylon for use;

[0062] 3) Use a 1100-mesh screen to screen the first-grade diatomite;

[0063] 4) Mix absolute alcohol and KH560 coupling agent according to the weight ratio of 97:3 to form a mixed solution;

[0064] 5) Stir and mix the screened diatomaceous earth and the mixed solution at high temperature according to the weight ratio of 100:10, and control the temperature between 140-160 degrees to remove alcohol;

[0065] 6) Put...

Embodiment 3

[0071] An environmentally friendly 3D printing consumable, the 3D printing consumable is compounded with diatomite, and the weight percentage of the diatomite is 40%; the above-mentioned 3D printing consumable is composed of nylon 610, nylon 612, diatomite and a coupling agent; The weight ratio of coupling agent to diatomaceous earth is 3:1000; the rest is a mixture of nylon 610 and nylon 612, and the ratio of nylon 612 and nylon 610 is 9:1.

[0072] 1) Vacuum dry the mixture of nylon 610 and nylon 612 at a temperature of 9-130 degrees for 11-13 hours;

[0073] 2) Wrap the dried nylon for use;

[0074] 3) Use a 1100-mesh screen to screen the first-grade diatomite;

[0075] 4) Mix absolute alcohol and KH560 coupling agent according to the weight ratio of 97:3 to form a mixed solution;

[0076] 5) Stir and mix the screened diatomite and the mixed solution at high temperature according to the weight ratio of 100:11, and control the temperature between 100-130 degrees to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com