A steam-cured brick produced from phosphorus tailings and phosphorus slag and its preparation method

A technology of phosphorus tailings and steam-cured bricks, which is applied in the field of building material preparation, can solve the problems of insufficient utilization of phosphorus tailings, increased investment in waterproofing projects, and poor water resistance of unburned bricks, so as to save transportation costs and low production costs , the effect of complete appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

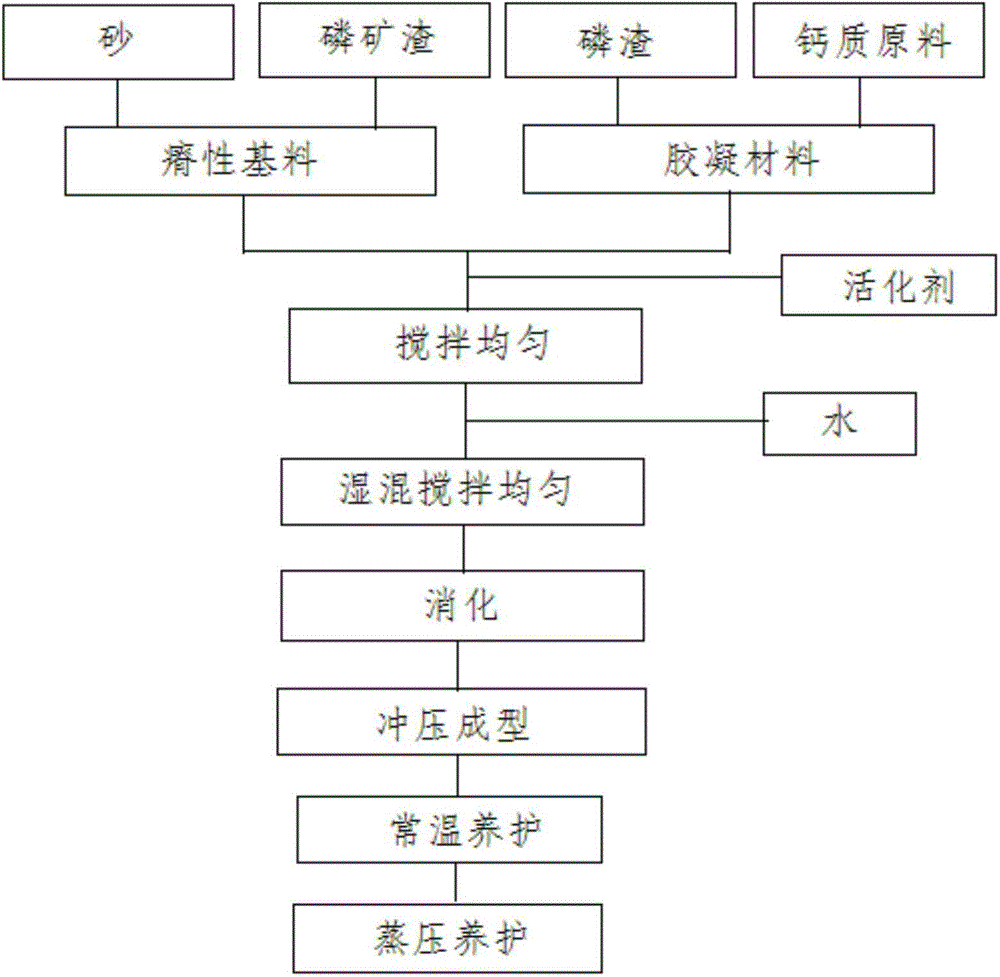

Method used

Image

Examples

Embodiment 1~92

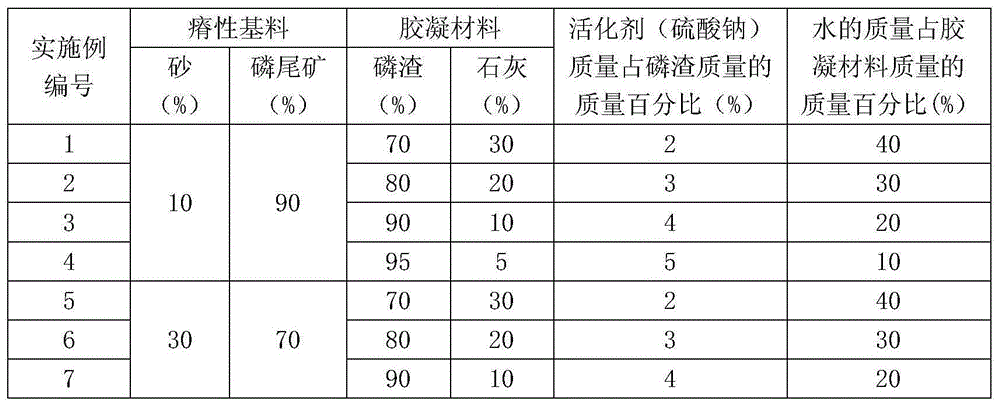

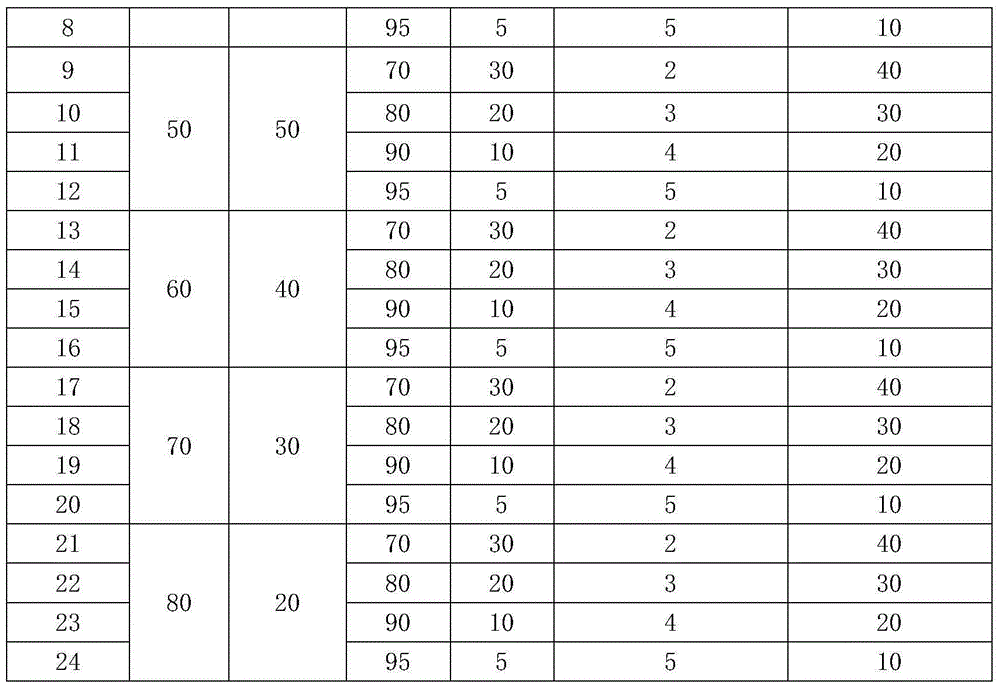

[0036] In Examples 1 to 24, a steam-cured brick produced by using phosphorus tailings and phosphorus slag has a mass ratio of barren base material to cementitious material of 8:2, and the distribution ratio of each component is shown in Table 1 below.

[0037] Table 1

[0038]

[0039]

[0040] In Examples 1-24, the steps of preparing the above steam-cured bricks:

[0041] (1) Weigh the sterile base material, gelling material, activator and water according to the ratio of the components in Table 1;

[0042](2) Pour the barren base material, gelling material and activator weighed in step (1) into the mixer and dry mix them evenly (stir for 3 to 10 minutes), then add the weighed water and mix them wet, stir After uniformity (stirring for 3-10 minutes), age the obtained material for 24 hours;

[0043] (3) Pour the aged material in step (2) into the mold for stamping and forming, the forming pressure is 25MPa, demould immediately after forming, and obtain the adobe;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com