Antitheft-door stamping-forming leftover regeneration device

A stamping forming and recycling device technology, applied in the direction of improving process efficiency, can solve the problems of increased operator workload, low casting quality, high energy consumption, etc., to shorten the casting and forming time, improve production efficiency, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

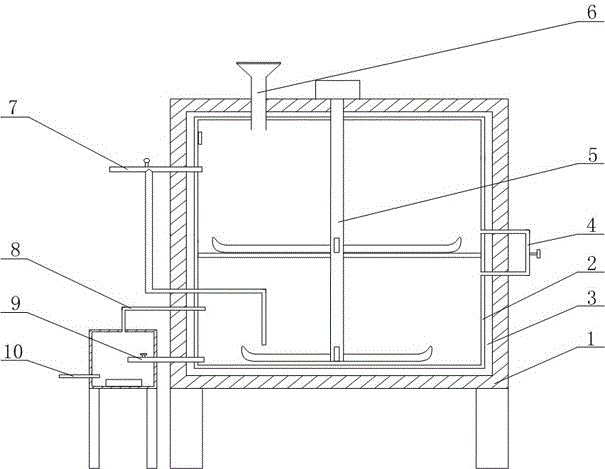

[0027] like figure 1As shown, the present invention is a regenerating device for stamping leftover materials of anti-theft doors, comprising a furnace shell 1 and a charging port 6, the inner side of the furnace shell 1 is provided with a furnace inner shell 2, and it is characterized in that the furnace shell 1 and the furnace inner shell 2 An electric heating layer 3 is arranged between them, and a baffle plate is arranged inside the furnace inner shell 2, and the baffle plate divides the inner space of the furnace inner shell 2 into two parts, wherein the upper part is a melting chamber, and the lower part is a static chamber, It also includes a casting box, the outer side of the casting box is connected with an exhaust pipe 10, and the exhaust pipe 10 communicates with the external space and the inside of the casting box, and the outer side of the furnace shell 1 is provided with a connecting pipe 4, a discharge pipe 9, and an air intake pipe 7 , gas pipe 8, wherein, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com