Production process of metal substrate with ion-plating black film layer and its metal substrate

A production process, ion plating technology, applied in the direction of metal material coating process, ion implantation plating, coating, etc., can solve the problem of target sputtering rate reduction, etc., to achieve strong wear resistance, dense and uniform film layer, bonded powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

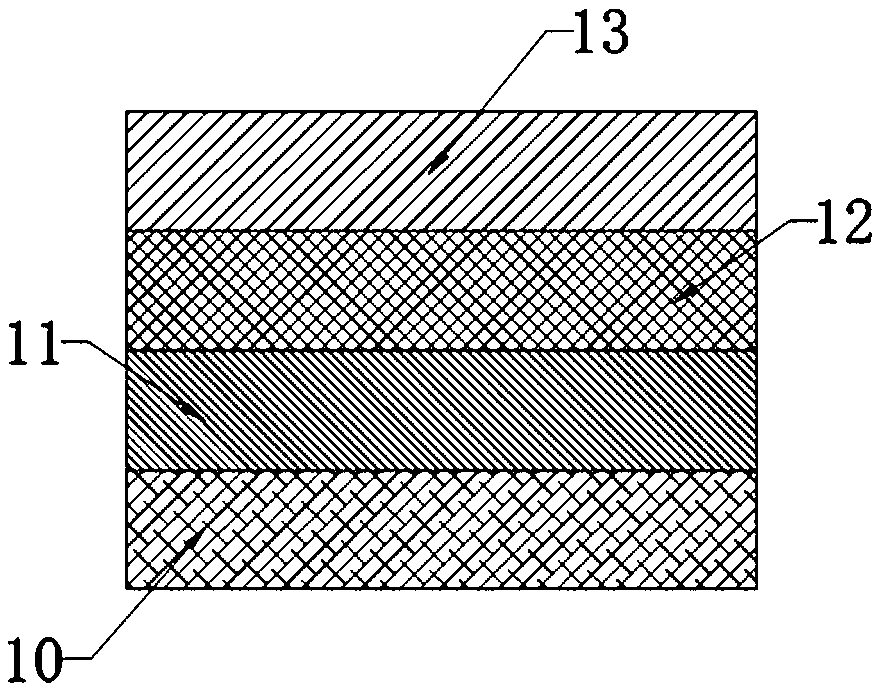

[0026] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

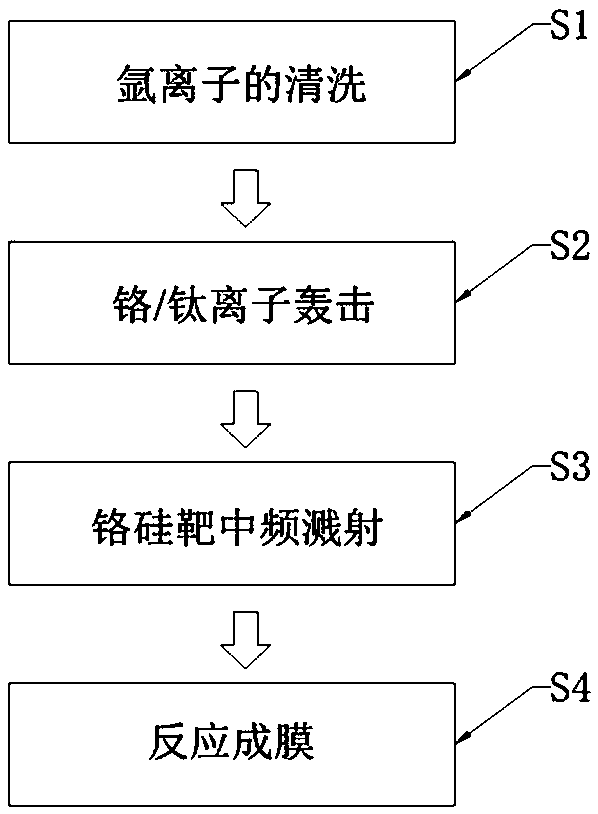

[0027] refer to figure 1 , the present invention a kind of production technique with ion plating black film layer metal substrate, comprises following process step:

[0028] S1. Argon ion cleaning

[0029] The vacuum degree of the coating chamber is 1.3-1.8Pa, the power supply voltage is 450-650V, and the duty ratio is 50%-80%. Ionize on the surface of the metal substrate under high voltage, discharge to generate glow to clean the surface of the metal substrate, and the cleaning time is 6 to 10 minutes;

[0030] S2, chromium / titanium ion bombardment

[0031] The vacuum degree of the coating chamber is 1.0×10 -1 ~1.8×10 -1 Pa, the power supply voltage is 200-300V, the duty cycle is 50%-70%, and the arc source current is 65A, so that the arc source can discharge the argon gas and the chromium / titanium target wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com