Bridge force measurement swivel support with real-time monitoring function

A real-time monitoring and functional technology, applied in bridges, measuring forces, bridge parts, etc., can solve problems such as the inability to quantify the unbalanced force of beams, and achieve the effects of simple structure, strong overload capacity, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical features of the present invention more clearly understood, the technical solution of the present invention will be described in detail below in conjunction with the drawings and embodiments.

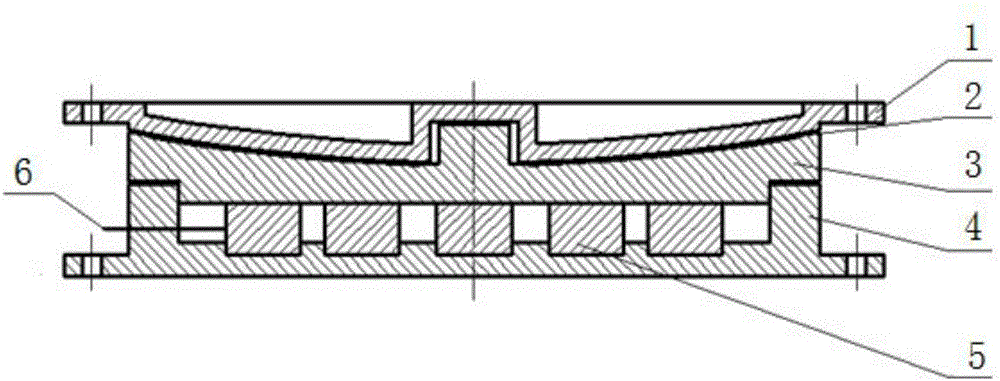

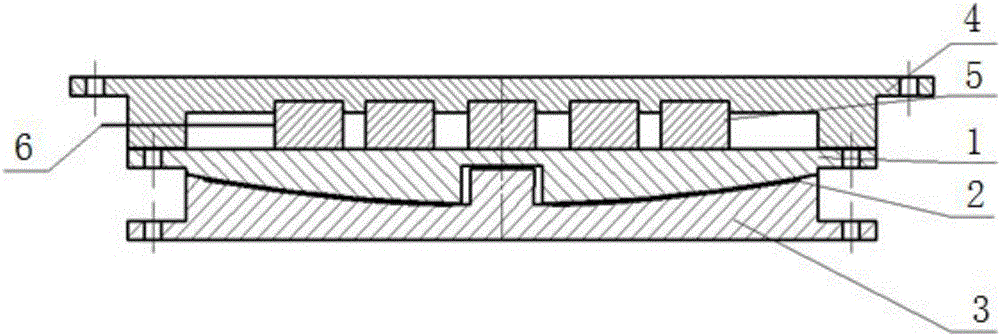

[0018] figure 1 It is one of the embodiments of the present invention.

[0019] see figure 1 , the bridge dynamometer swivel bearing with real-time monitoring function in this embodiment includes an upper ball pendulum 1 and a lower ball pendulum 3 that fit and install, and the upper ball pendulum 1 and the lower ball pendulum 3 constitute a spherical friction pair, so A wear-resistant plate 2 is installed between the upper ball pendulum 1 and the lower ball pendulum 3, and the bottom of the lower ball pendulum 3 is provided with a sensor mounting plate 4 that fits with it and has several grooves on it. Several sensors 5 corresponding to several grooves are installed between the lower ball pendulum 3 and the sensor mounting plate 4, and the sensors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com