Special directional rod for powder wall machine

A technology of directional rods and powder wall machines, which is applied in the field of directional rods, can solve problems such as inconvenient movement, and achieve the effects of convenient connection, strengthening strength, and preventing dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

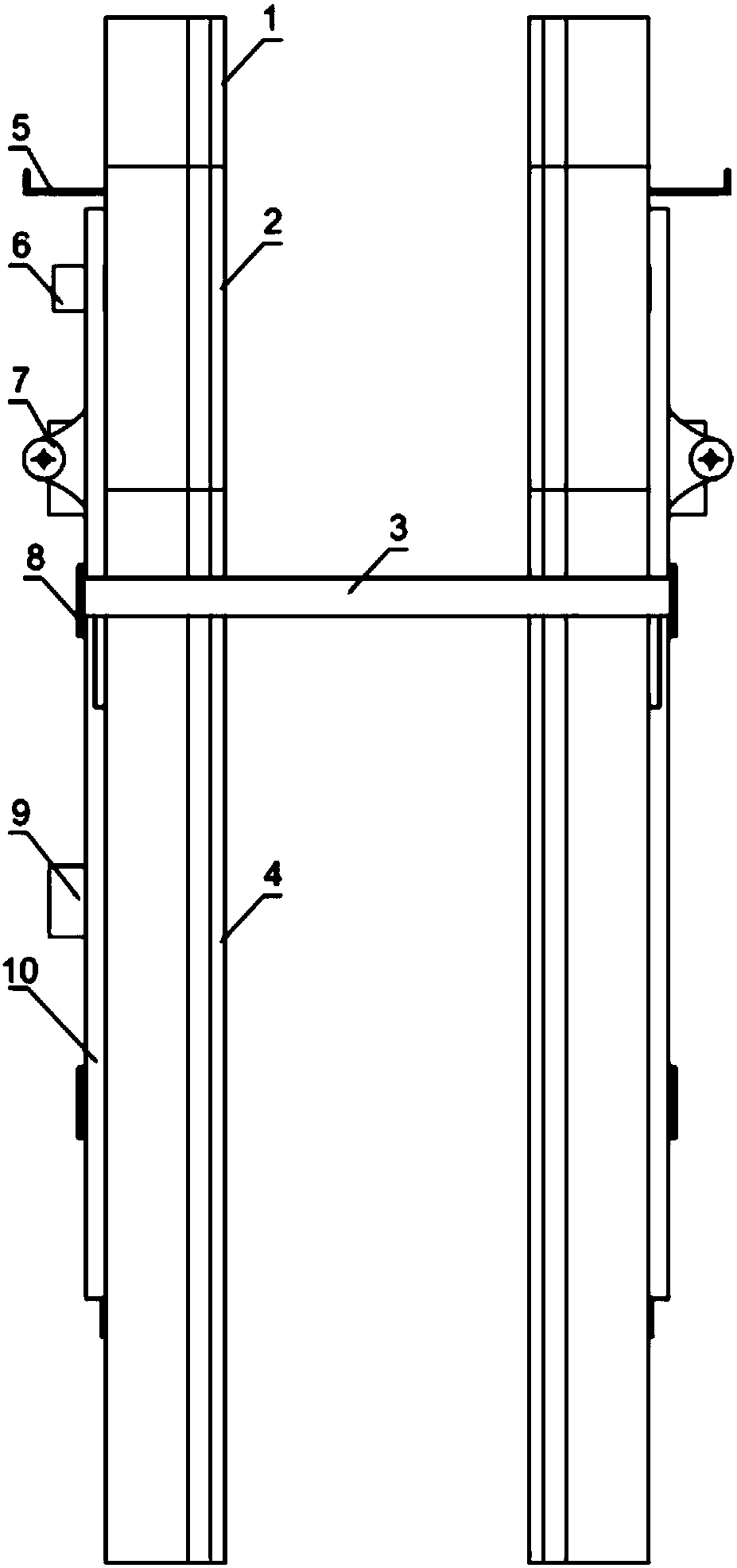

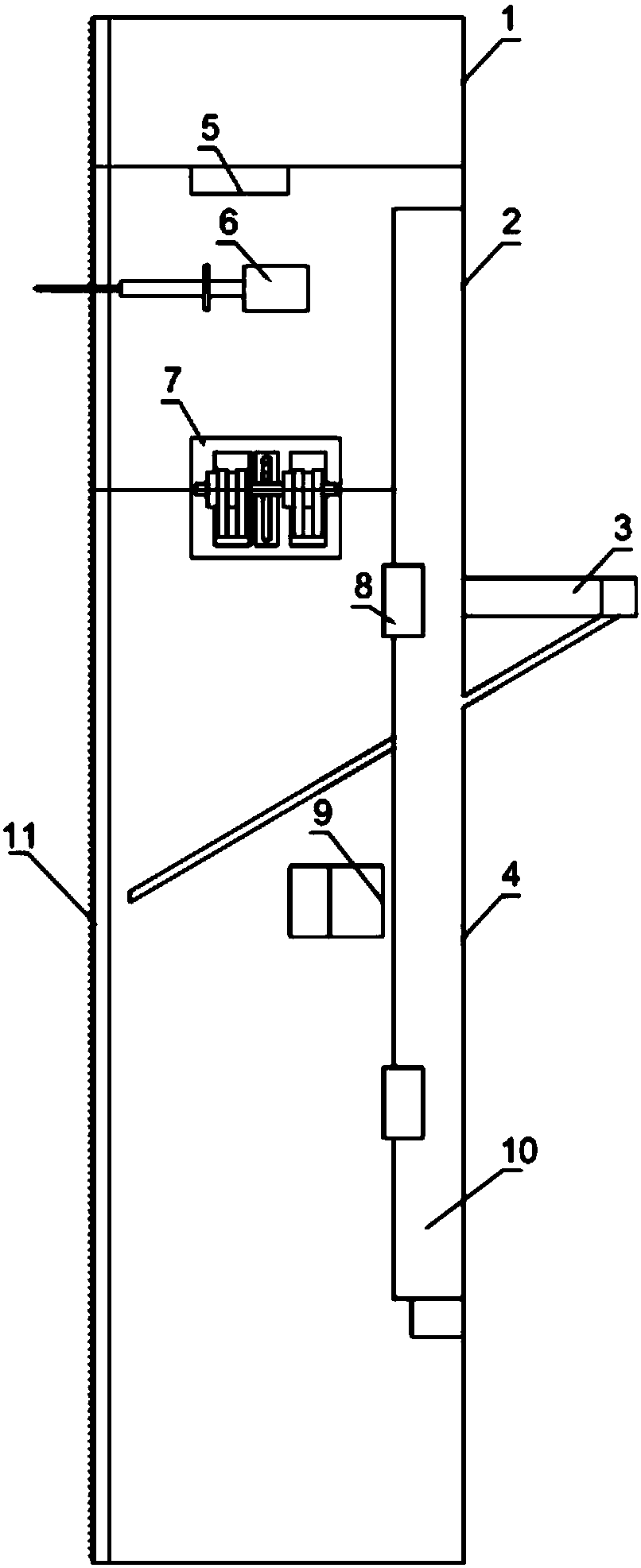

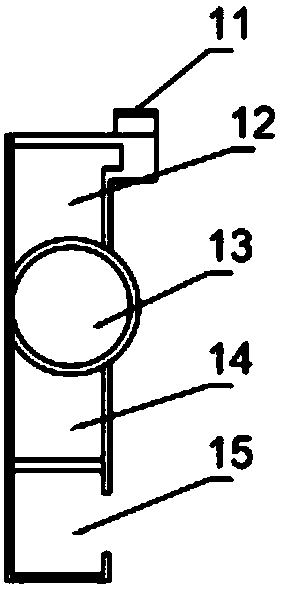

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0019] Examples such as Figure 1-7 As shown, a special directional rod for a powder wall machine, the directional rod is made of aluminum alloy, has four cavities inside, and a set of gear teeth 11 on the outside, and the four cavities are the first cavity 15 and the second cavity in turn. 14. The third cavity 13 and the fourth cavity 12. The first cavity 15 is a guide rail cavity with an opening on the inside. The guide rail cavity is connected to the guide rail shaft of the powder wall host. The powder wall host is equipped with two guide rail shafts up and down. The guide rail shaft is placed in the guide rail cavity at the same time to prevent the orientation rod from tilting; the second cavity 14 and the fourth cavity 12 are built-in connecting rod cavities, the third cavity 13 is a circular cavity, and the third cavity 13 lower section Insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com