Cross type fixed-connection clamp

A cross-type, connecting card technology, which is applied in the connection of scaffolding, building structure support, building structure support, etc., can solve the problems of simple connection of pipelines, cumbersome operation process of capacitor bushing connection, and applicable conditions of electrofusion connection. Limited and other problems, to achieve the effect of novel overall structure design, low manufacturing cost and fast connection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

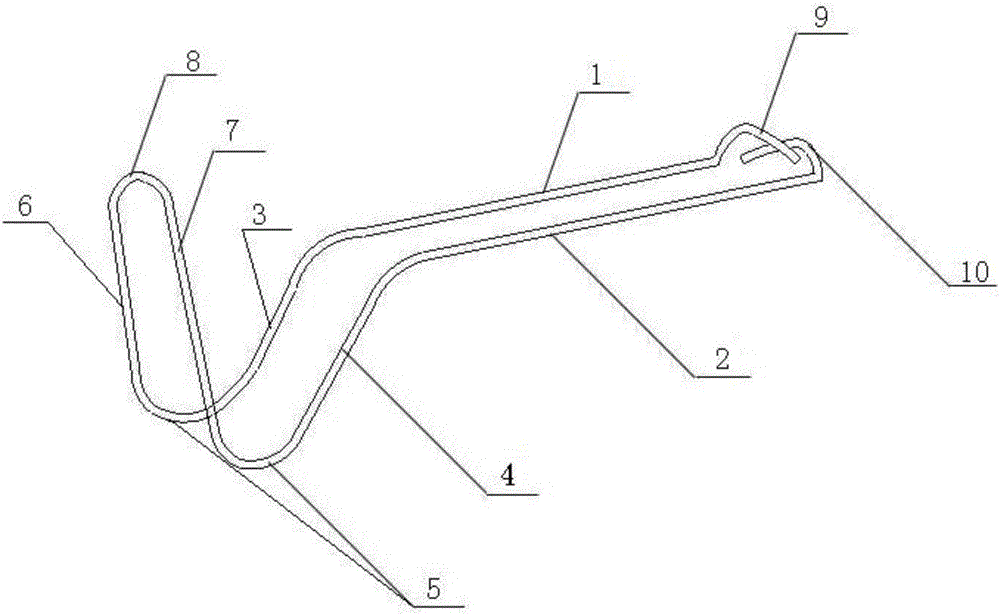

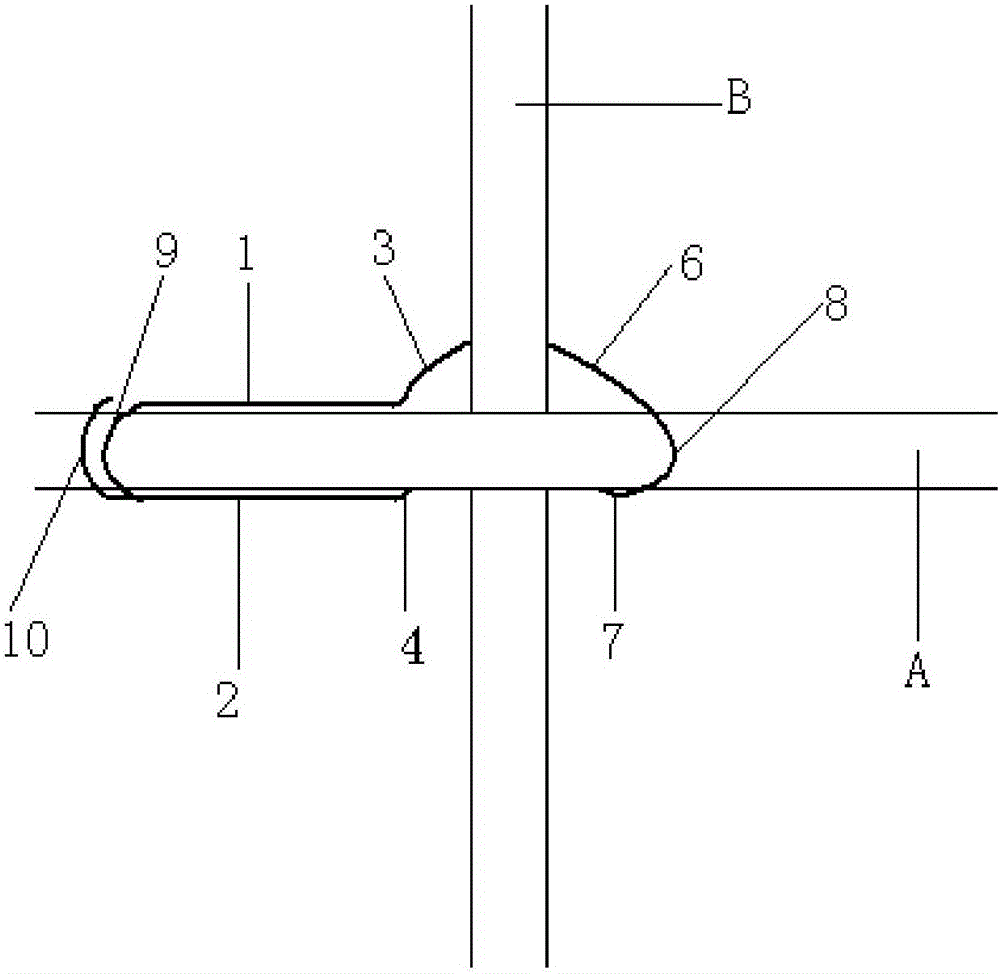

[0012] The cross-type fixed connection buckle involved in this embodiment is integrally twisted from a single steel wire (such as figure 1 shown), its main structure includes the first main pole 1, the second main pole 2, the No. Section 7, cross bar protrusion 8, first cross bar buckle 9 and second cross bar buckle 10, the ends of the first main bar 1 and the second main bar 2 parallel to each other are respectively provided with the first cross bar buckle 9 of the same structure and the second cross bar buckle 10, which are respectively used to receive the connecting pipe in an encircling manner from the upper end and the lower end; the front end of the first main bar 1 is the No. The other end of 3 is connected with upwardly curved No. Ⅲ vertical bar segment 6 through the vertical bar protrusion 5 of the concave structure, and the front end of the second main bar 2 is the downwardly curved No. 2 vertical bar segment 4, and the No. Ⅱ vertical bar segment 4 The other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com