Coal mine underground bottom pumping roadway crossing borehole anti-hole spraying construction method

A technology of layer-penetrating drilling and construction methods, which is applied in mining equipment, earthwork drilling, and flushing boreholes, etc., and can solve problems such as gas accidents, gas over-limit alarms, and production impacts, and achieve the effect of avoiding spray holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

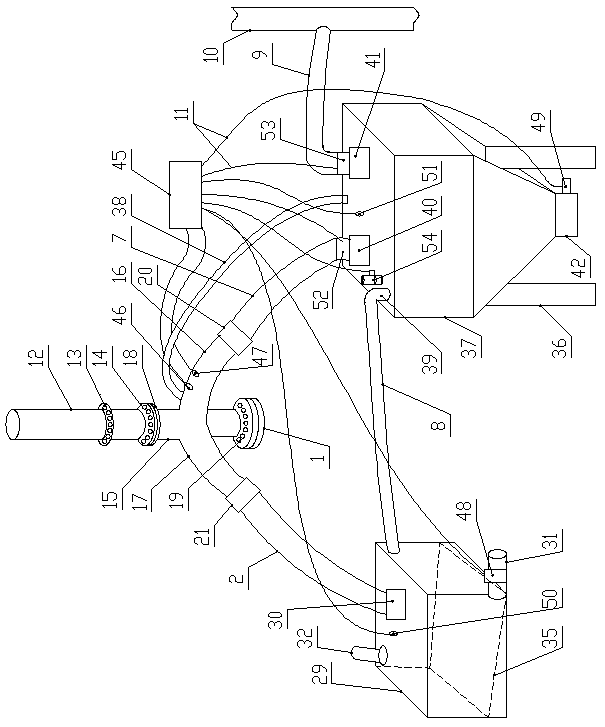

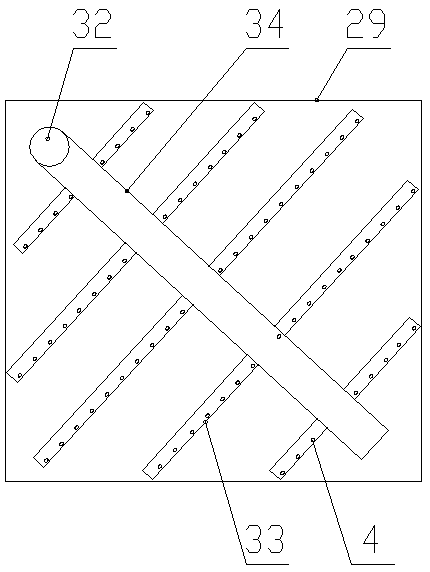

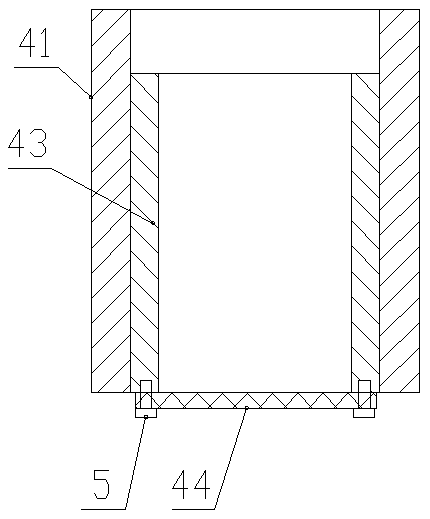

[0038] Such as Figure 1-Figure 4 As shown, the coal mine bottom pumping roadway of the present invention cross-layer drilling blowout prevention hole construction method comprises the following steps,

[0039] (1) Select the drilling location of the bottom pumping roadway, first use a larger drill bit to construct the reaming section at the outer port of the drilling hole, and install the sealing pipe fittings of the drilling reaming section in the reaming section;

[0040] (2) The upper part of the wing-shaped water slag gas splitter is provided with a connection port, and the lower part of the wing-shaped water slag gas splitter has three connection ports: upper, middle and lower. The connection port is connected with the lower port of the sealing pipe fitting of the drilling reaming section;

[0041] (3) The upper and lower ports of the wing-shaped slag gas diverter are respectively connected to the negative pressure accumulator and the slag collector, and the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com