A kind of downhole blowout preventer pressure maintaining drilling method

A drilling method and drill pipe technology, applied in drill pipe, drill pipe, directional drilling and other directions, can solve the problems of changing the integrity of coal and rock mass, gas overrun, and hole collapse, and achieve the convenience of popularization and use and the service life. Long, friction-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

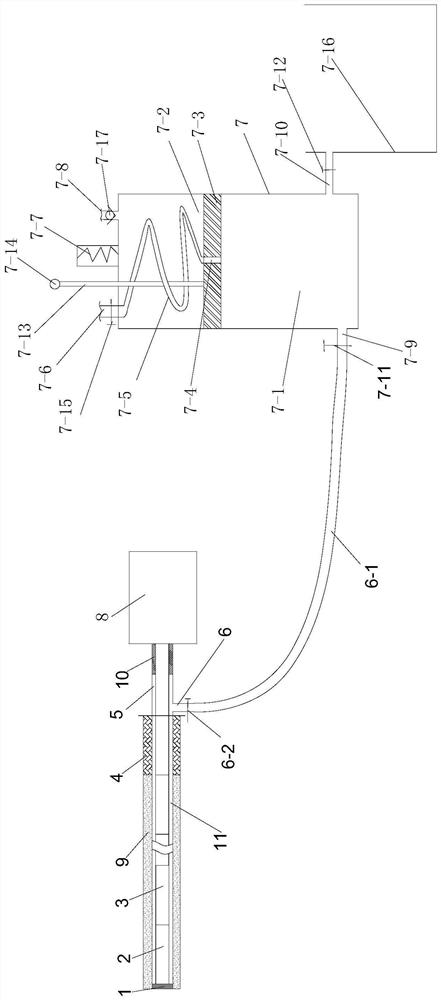

[0052] Such as Figure 1 to Figure 4 As shown, a kind of downhole blowout preventer pressure maintaining drilling method of the present invention comprises the following steps:

[0053] Step 1. Drilling and sealing: Utilize the drilling rig 8 and the initial drill rod mechanism that cooperates with the drilling rig 8 and extends into the coal formation 9 to drill at the design position according to the design azimuth and design inclination until the drilling depth reaches the design depth, the design depth is equal to the length of the sealing section 4, and the length of the initial drill rod mechanism is not less than the length of the sealing section 4;

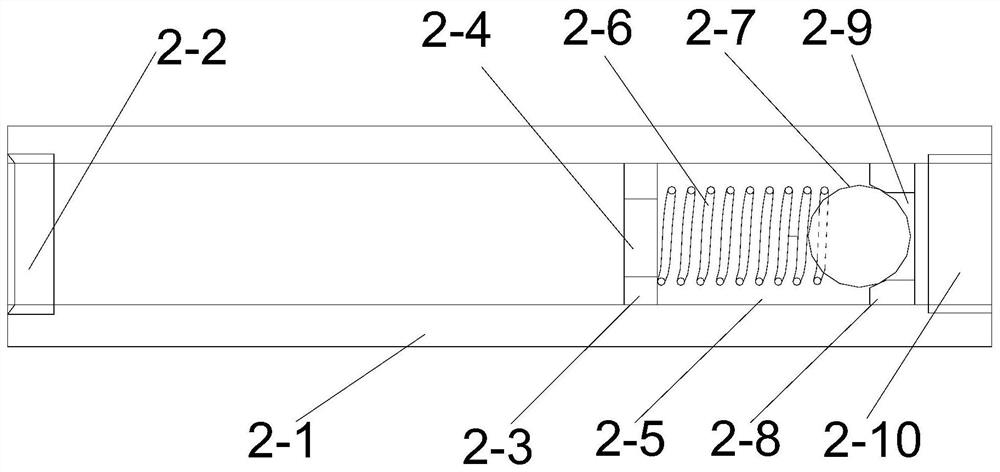

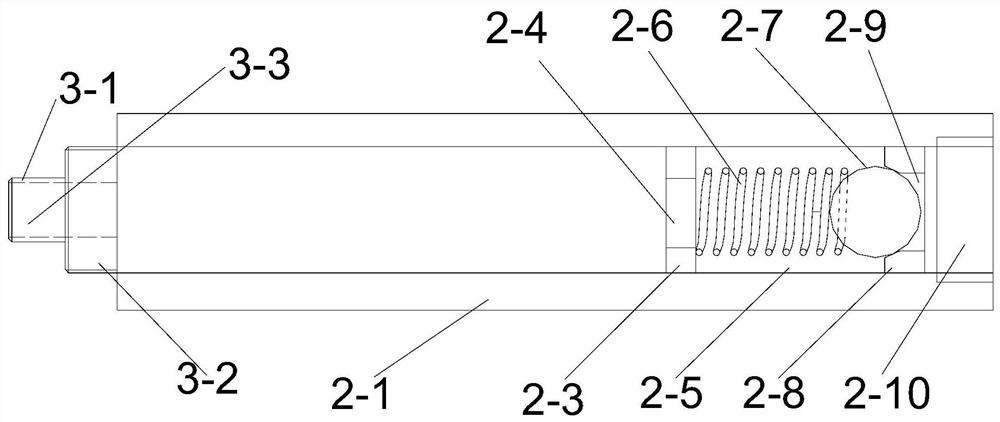

[0054] The initial drill rod mechanism includes an independent drill rod 2, a drill bit 1 installed on the front side of the independent drill rod 2, and a connecting drill rod assembly installed on the rear side of the independent drill rod 2, and the connecting drill rod assembly includes N sequentially connected Connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com