Static splitting agent for pile head of cast-in-place pile

A cast-in-situ pile and pile head technology, applied in the field of material science, can solve the problems of low efficiency of manual removal, damage and damage of the lower pile body, etc., and achieve the effects of convenient storage and transportation, large expansion force, and avoiding spray holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

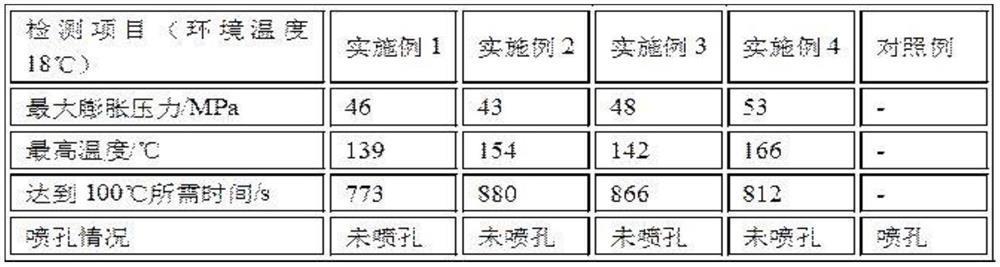

Examples

Embodiment 1

[0029] The preparation method of the pile head static splitting agent for cast-in-situ piles comprises the following steps.

[0030] (1) Use percalcined calcium oxide that has been calcined at a high temperature of about 1500°C for a calcination time of not less than 55 hours as the hydrated expansion product, Portland cement as the hydration hardening agent, expanded graphite as the cooling agent, and tartaric acid as the hydration delay Agent, aluminum powder is used as expansion agent, water reducer is UNF-4 early strength water reducer, and quartz powder is used as reinforcing material.

[0031] (2) The weight ratio of each component is: percalcined calcium oxide 70%, Portland cement 23.8%, expanded graphite 1%, tartaric acid 0.2%, aluminum powder 4.8%, UNF-4 superplasticizer 0.2%, Quartz powder 0%.

[0032] (3) The percalcined calcium oxide is ground and passed through a 0.08mm sieve, and each component material is ground and sieved and mixed according to the proportion,...

Embodiment 2

[0037] The preparation method of the pile head static splitting agent for cast-in-situ piles comprises the following steps.

[0038] (1) Use percalcined calcium oxide that has been calcined at a high temperature of about 1500°C for a calcination time of not less than 55 hours as the hydrated expansion product, Portland cement as the hydration hardening agent, expanded graphite as the cooling agent, and tartaric acid as the hydration delay Agent, aluminum powder is used as expansion agent, water reducer is UNF-4 early strength water reducer, and quartz powder is used as reinforcing material.

[0039] (2) The weight ratio of each component is: perburned calcium oxide 75%, Portland cement 15.8%, expanded graphite 1.8%, tartaric acid 0.9%, aluminum powder 3.9%, UNF-4 early strength superplasticizer 1.4%, Quartz powder 1.2%.

[0040] (3) The percalcined calcium oxide is ground and passed through a 0.08mm sieve, and each component material is ground and sieved and mixed according t...

Embodiment 3

[0044] The preparation method of the pile head static splitting agent for cast-in-situ piles comprises the following steps.

[0045] (1) Use percalcined calcium oxide that has been calcined at a high temperature of about 1500°C for a calcination time of not less than 55 hours as the hydrated expansion product, Portland cement as the hydration hardening agent, expanded graphite as the cooling agent, and tartaric acid as the hydration delay Agent, aluminum powder is used as expansion agent, water reducer is UNF-4 early strength water reducer, and quartz powder is used as reinforcing material.

[0046] (2) The weight ratio of each component is: perburned calcium oxide 79%, Portland cement 10.3%, expanded graphite 2.2%, tartaric acid 1.5%, aluminum powder 2.2%, UNF-4 early strength superplasticizer 2.1%, Quartz powder 2.7%.

[0047] (3) The percalcined calcium oxide is ground and passed through a 0.08mm sieve, and each component material is ground and sieved and mixed according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com