Wheel-side differential lock axle

A differential lock and axle technology, which is applied in the direction of differential transmission, axles, wheels, etc., can solve problems such as poor working conditions, affecting vehicle traffic, and many potholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

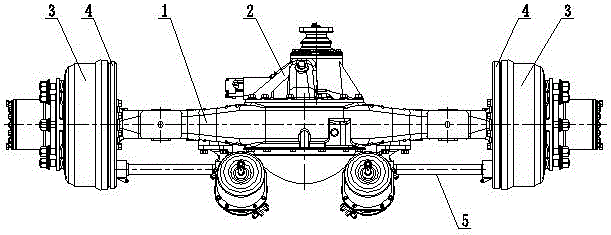

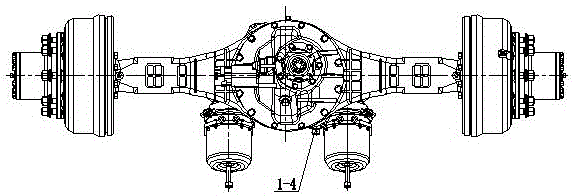

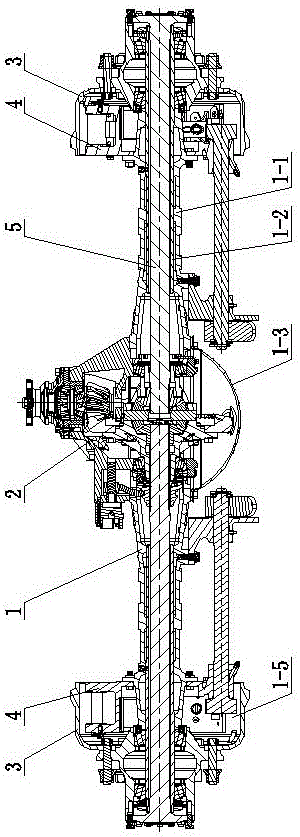

[0016] The wheel differential lock axle is composed of rear axle housing assembly 1, main reducer assembly 2, hub brake drum assembly 3, brake assembly 4, half shaft 5 and differential lock. 2 Installed in the middle of the rear axle housing assembly 1, the two ends of the rear axle housing assembly 1 are respectively equipped with the hub brake drum assembly 3 and the brake assembly 4, and the two brake assemblies 4 are connected to the hub system through the half shaft 5 The moving drum assembly 3 is connected, and it is characterized in that: the main reducer assembly 2 is composed of a main reducer housing 2-1, a differential lock, a differential bearing adjusting nut 2-5, a snap ring 2-8, a differential Transmission bearing cover 2-9, half shaft gear 2-10, differential case 2-11, driven bevel gear 2-12, cross shaft 2-13, planetary gear 2-14, differential bearing 2-15 , driving bevel gear 2-16, bearing seat 2-17, oil seal seat 2-18 and flange assembly 2-19, the main reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com