Cantilever angle adjusting mechanism

An angle adjustment and cantilever technology, applied in supporting machines, mechanical equipment, machines/supports, etc., can solve the problems of small weighing range, limited cylinder stroke, and high production cost, and achieve a wide range of adjustment load-bearing, large adjustment angle, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

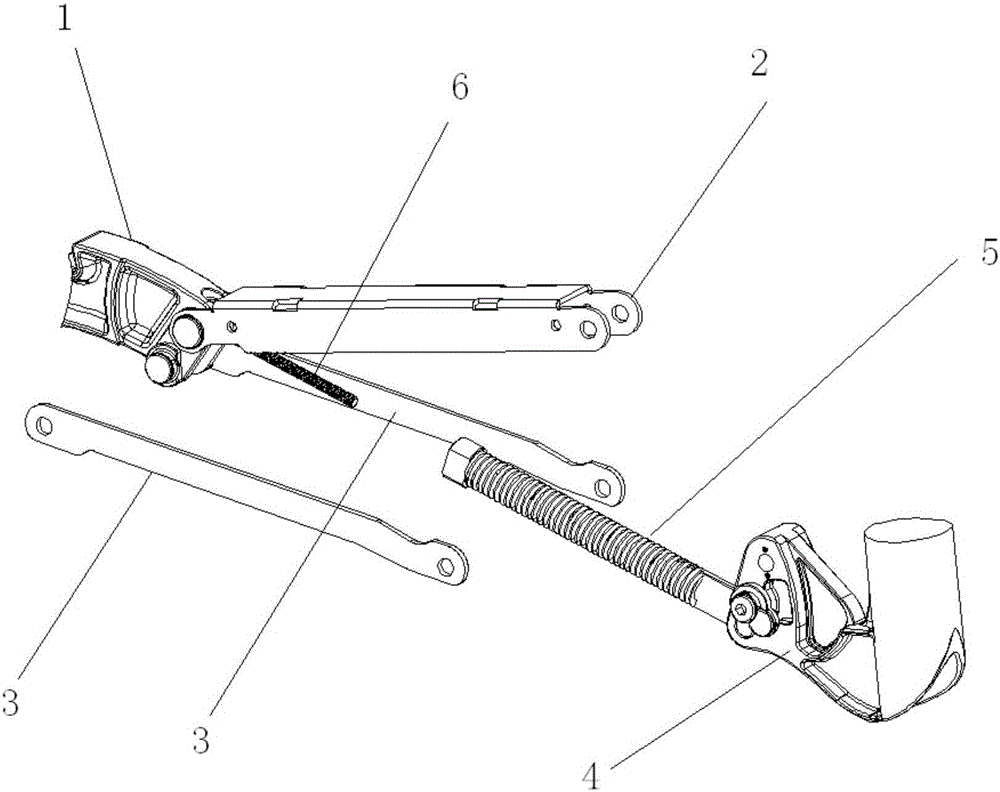

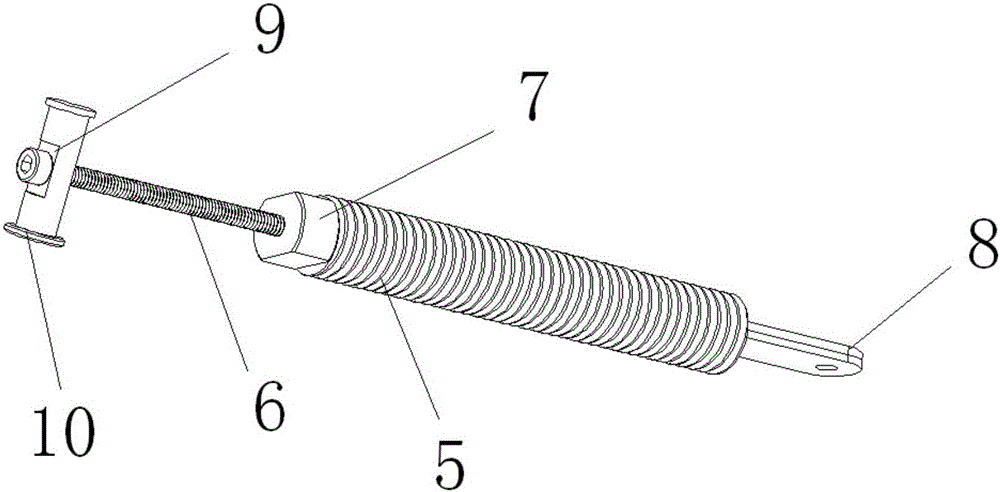

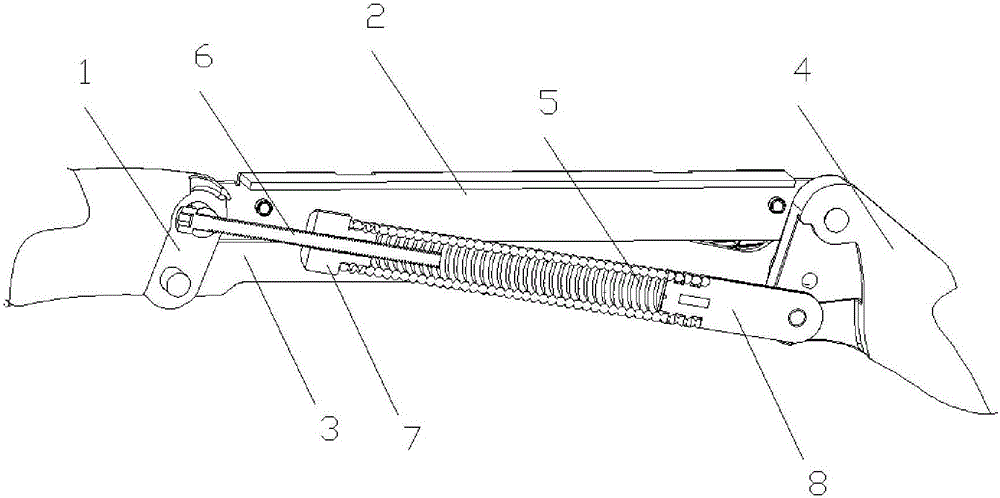

[0013] Embodiment: A cantilever angle adjustment mechanism, including a support 1, first and second cantilever connecting rods 2, 3, a connecting piece 4, an elastic body 5, and an adjustment shaft 6, the support 1, the first and second cantilever The connecting rods 2, 3 and the connecting piece 4 are hinged to form a parallel four-bar linkage mechanism, in which the first and second cantilever connecting rods 2, 3 are arranged in parallel, and the adjusting shaft 6 is coaxially connected with the elastic body 5 to form an angle adjusting mechanism. The two ends of the angle adjustment mechanism are respectively hinged with the two diagonal hinge shafts 10 of the above-mentioned parallel four-bar linkage mechanism, and the length of the adjustment shaft 6 can be adjusted.

[0014] When in use, install the equipment that requires angle adjustment on the connecting piece 4, and the angle adjustment mechanism composed of the support 1, the first and second cantilever links 2, 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com