Illuminating module and illuminating device comprising same

A lighting module, lighting device technology, applied in lighting devices, fixed lighting devices, lighting device components and other directions, can solve the problems of complex process, high LED temperature, poor heat conduction effect, etc., to improve heat conduction conditions and efficient heat conduction paths , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

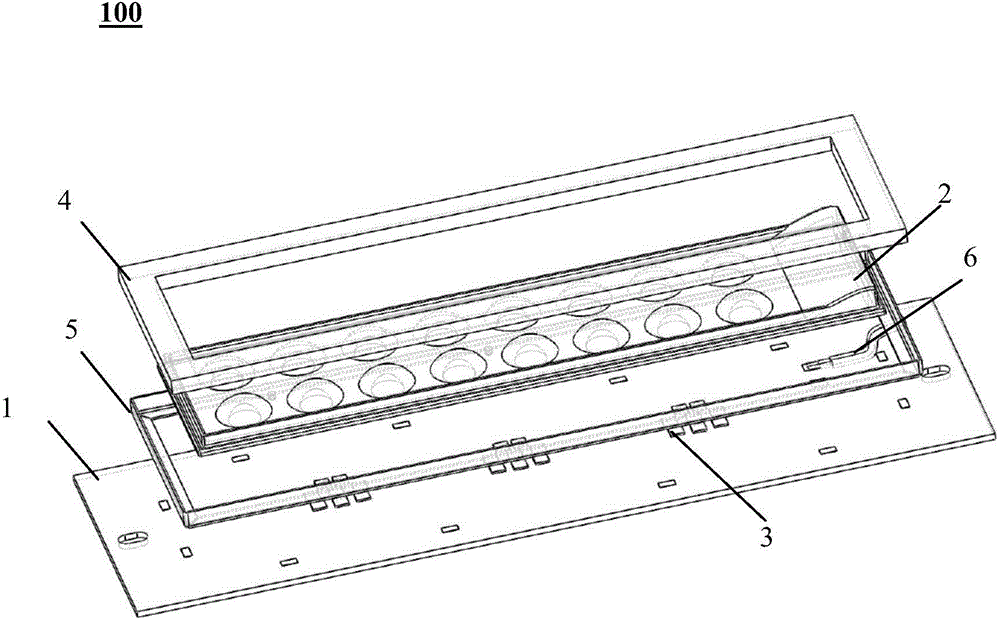

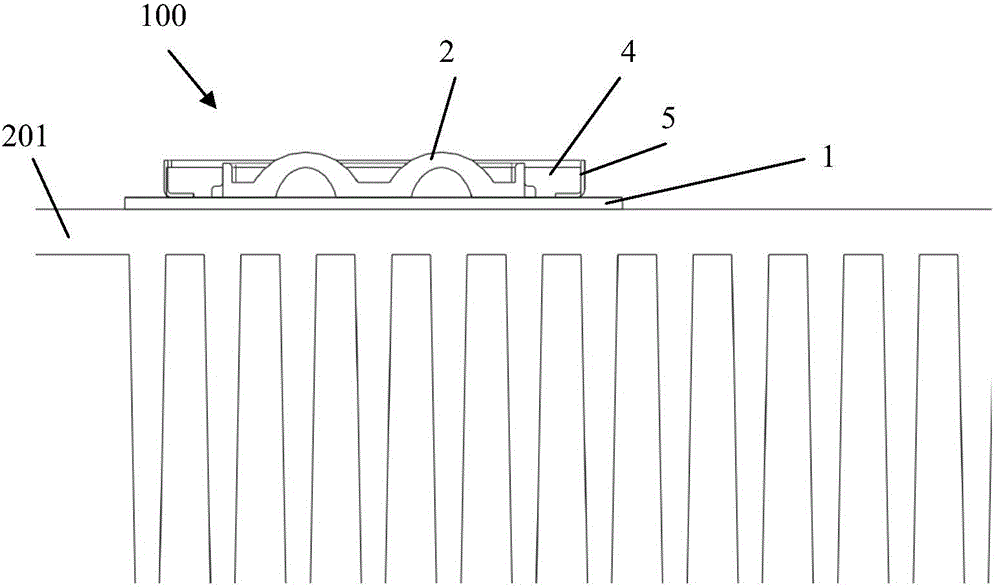

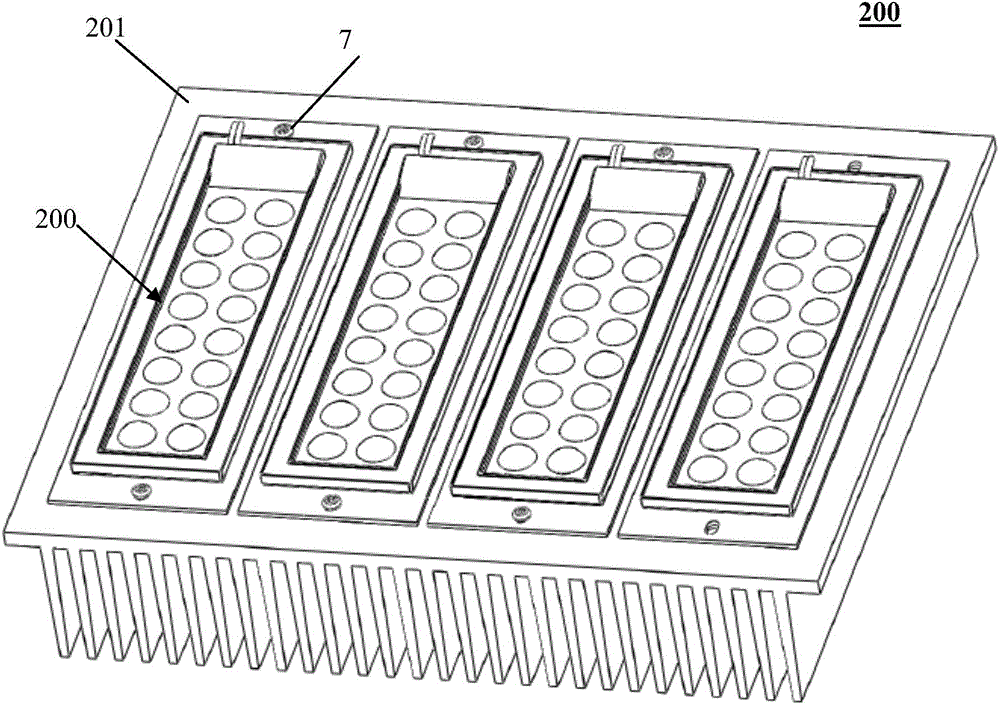

[0020] figure 1 An exploded schematic view of the lighting module 100 according to the present invention is shown. The lighting module 100 according to the present invention includes such as figure 1 The circuit board 1 shown is a lens 2 for covering the light-emitting element 3 arranged on the first side of the circuit board 1 . The light emitting element 3 according to the embodiment of the present invention can preferably be designed as an LED. In addition, in order to manufacture the lens 2 and the circuit board 1 into a package, an encapsulation material 4 is also provided on the first side of the circuit board 1, wherein the encapsulation material 4 can protect the bonding area between the lens 2 and the circuit board 1 The gap is filled.

[0021] When the encapsulation material 4 is arranged on the circuit board 1, since the initial state of the encapsulation material 4 is often liquid or gel-like, such as a potting material, a frame 5 is also preferably provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com