Substrate-free LED device and manufacturing method thereof

A technology of LED devices and manufacturing methods, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of no improvement in heat dissipation of the packaging structure, reduction of packaging size, reduction of packaging cost and thickness, etc., so as to save costs and process steps, Effects of improved reliability and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

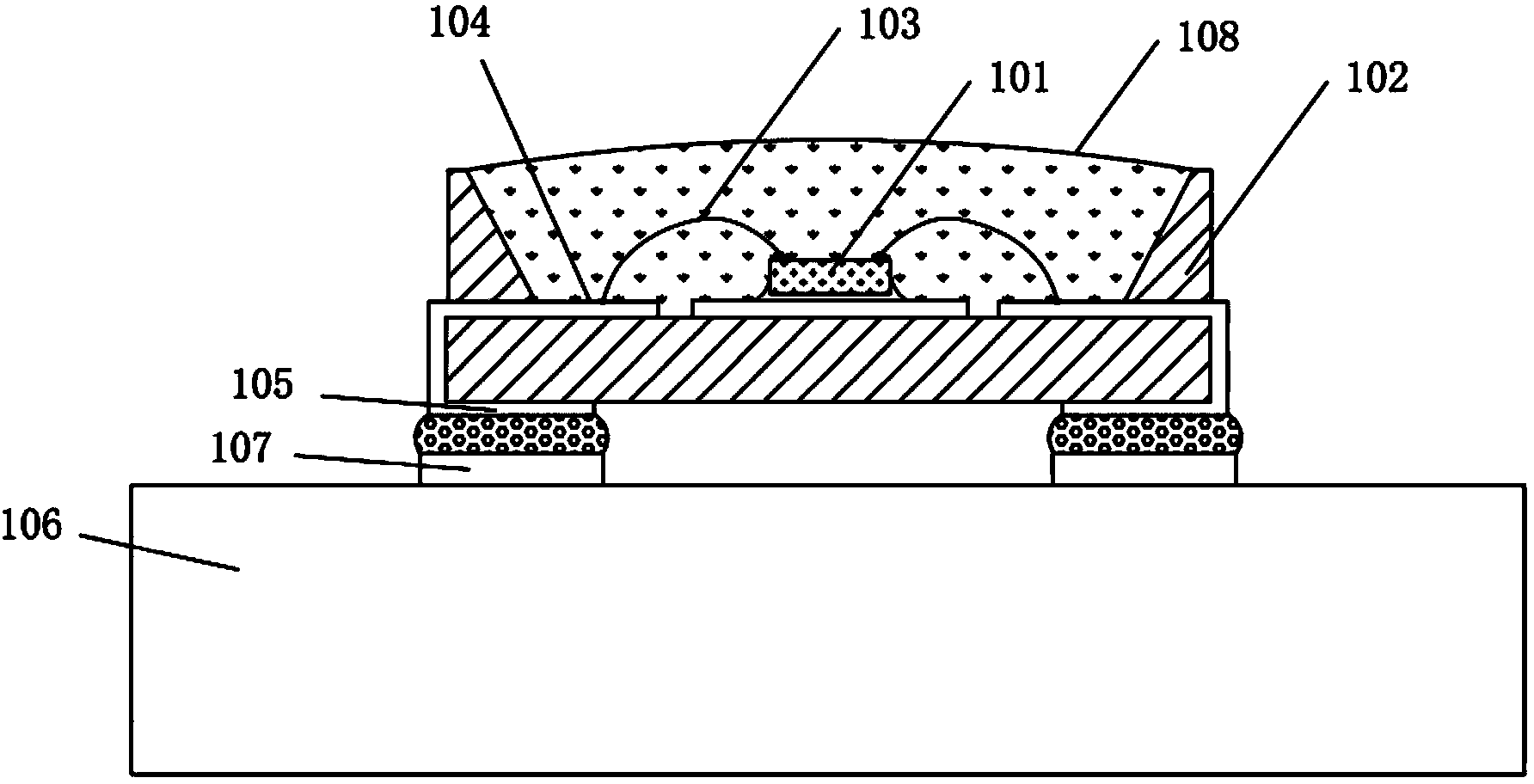

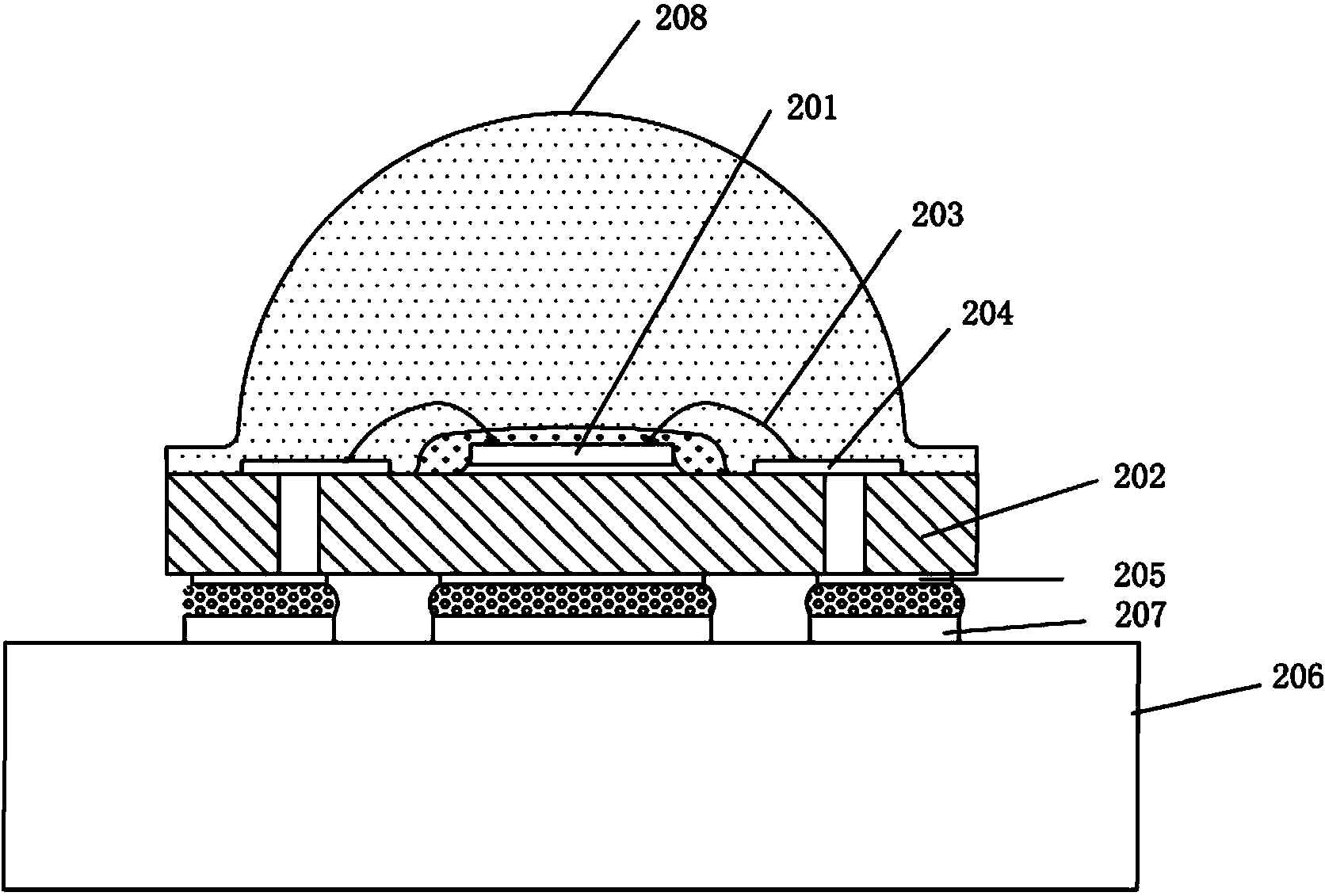

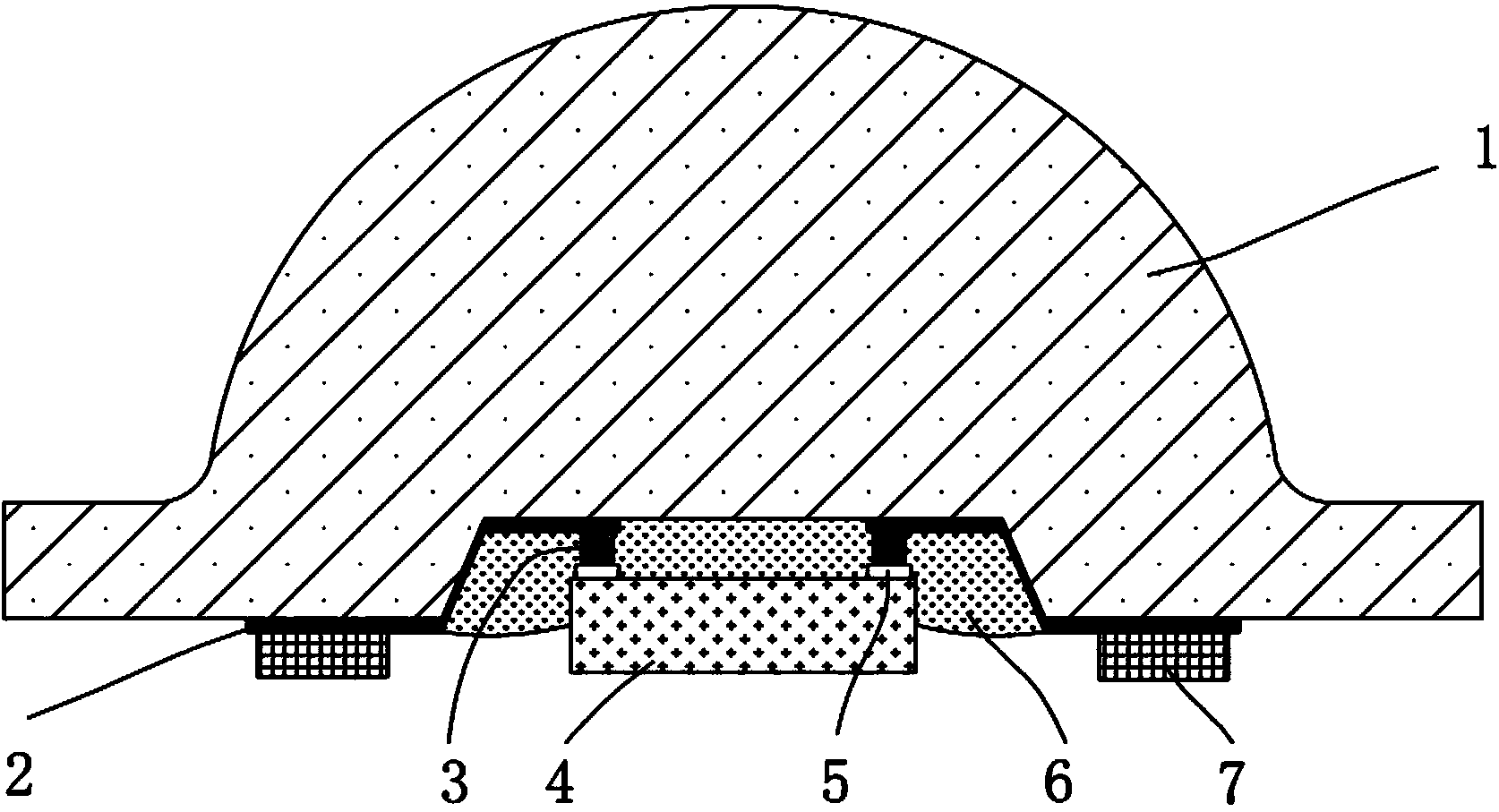

[0077] see image 3 Shown is a schematic structural view of an LED device with an integrated lens substrate in a typical embodiment of the present invention. The LED device includes a preformed lens 1 and at least one LED chip 4 (hereinafter referred to as chip). The lens 1 is provided with a metal or transparent conductive material wiring layer 2, and the chip has a metal electrode 5. The metal wiring layer 2 on the lens 1 (referred to as wiring 2) and the metal electrode 5 on the chip 4 are connected by a lead bump 3. The lens The external lead electrode 7 of the LED device (also referred to as "external electrode" for short below) is provided at a specific position of the wiring 2 on the LED device. Usually the chip is fixed in the groove at the bottom of the lens, and the groove is filled with transparent colloid 6 through the underfill process and cured, so that there are no air bubbles between the LED chip and the lens, reducing reflection loss. The lower surface of th...

Embodiment 2

[0095] The structure of a kind of LED device of the present embodiment can also refer to Figure 3-Figure 8 , and the fabrication process of the device is the same as in Example 1.

[0096] see Figure 10 Shown is a schematic diagram of a thermoelectric separation assembly of an LED device integrated with a lens substrate of the present invention. In this device, the chip 4 is a front-mounted chip, and its positive and negative electrodes are all on the upper surface of the chip. electrical connection. The lower surface of the chip 4 is directly connected to the top of the heat sink 1002 through thermal grease, eutectic soldering or other methods, so as to achieve low thermal resistance. The external electrodes 7 on the lens 1 are electrically connected to the outside through a PCB 1001 of a specific shape. The device is fixed on the heat sink 1002 through the pressing piece 1004 , the washer 1003 and the screw 1005 .

[0097] In addition, the electrical connection between t...

Embodiment 3

[0100] Please also see Figure 11-Figure 12 ,in Figure 11 It is a schematic top view diagram of an LED device (hereinafter referred to as the device) that includes a lens substrate integrated with multiple lens units. Figure 12 yes Figure 11 A schematic cross-sectional view of the device along the B-B' direction is shown.

[0101] The device is a multi-unit module integrated on the lens substrate 1101, wherein the main body of each unit lens can be designed as an aspheric surface according to the needs of the light type. The chips 4 in each unit module are connected in series / parallel through the wiring 1102 on the lens substrate 1101 . An external electrode is arranged on the edge of the lens substrate, and the external electrode cooperates with the lens substrate to form a plug 1103, which can form a plug-in connection with an external circuit through a matching socket. The lens substrate 1101 may be provided with a positioning hole 1104 . The device can be fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com