High load anti-friction plate testing machine

A technology of anti-friction plate and testing machine, which is applied in the field of testing machines, can solve problems such as high specific pressure, eccentric wear, and failure to reflect high-temperature wear status, and achieve the effect of strong practicability and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

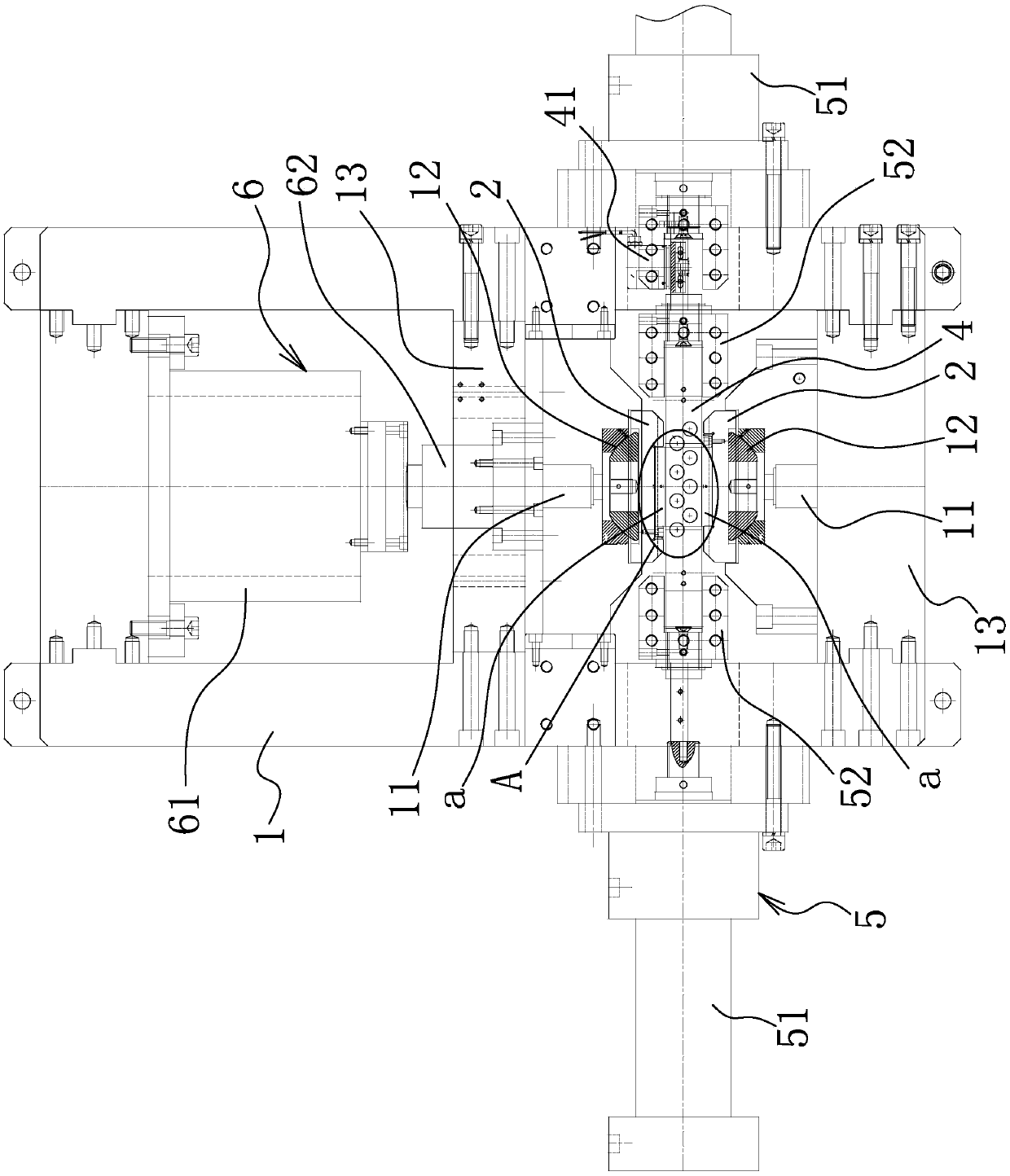

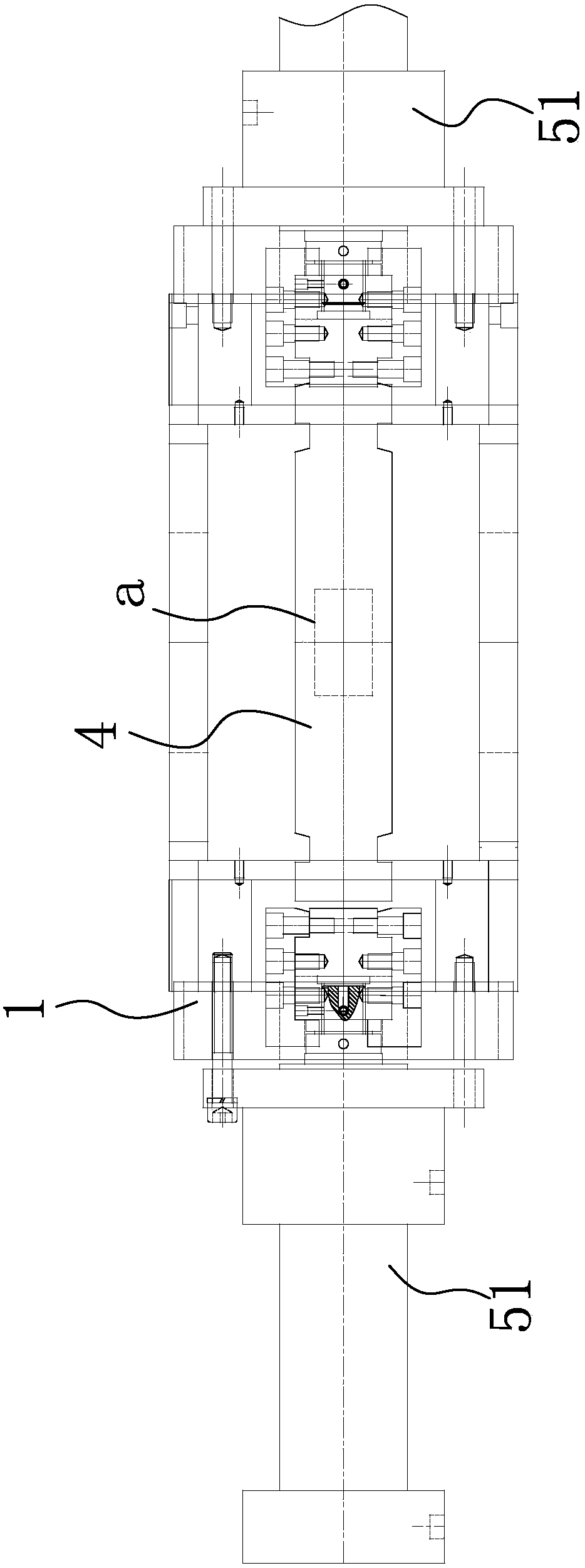

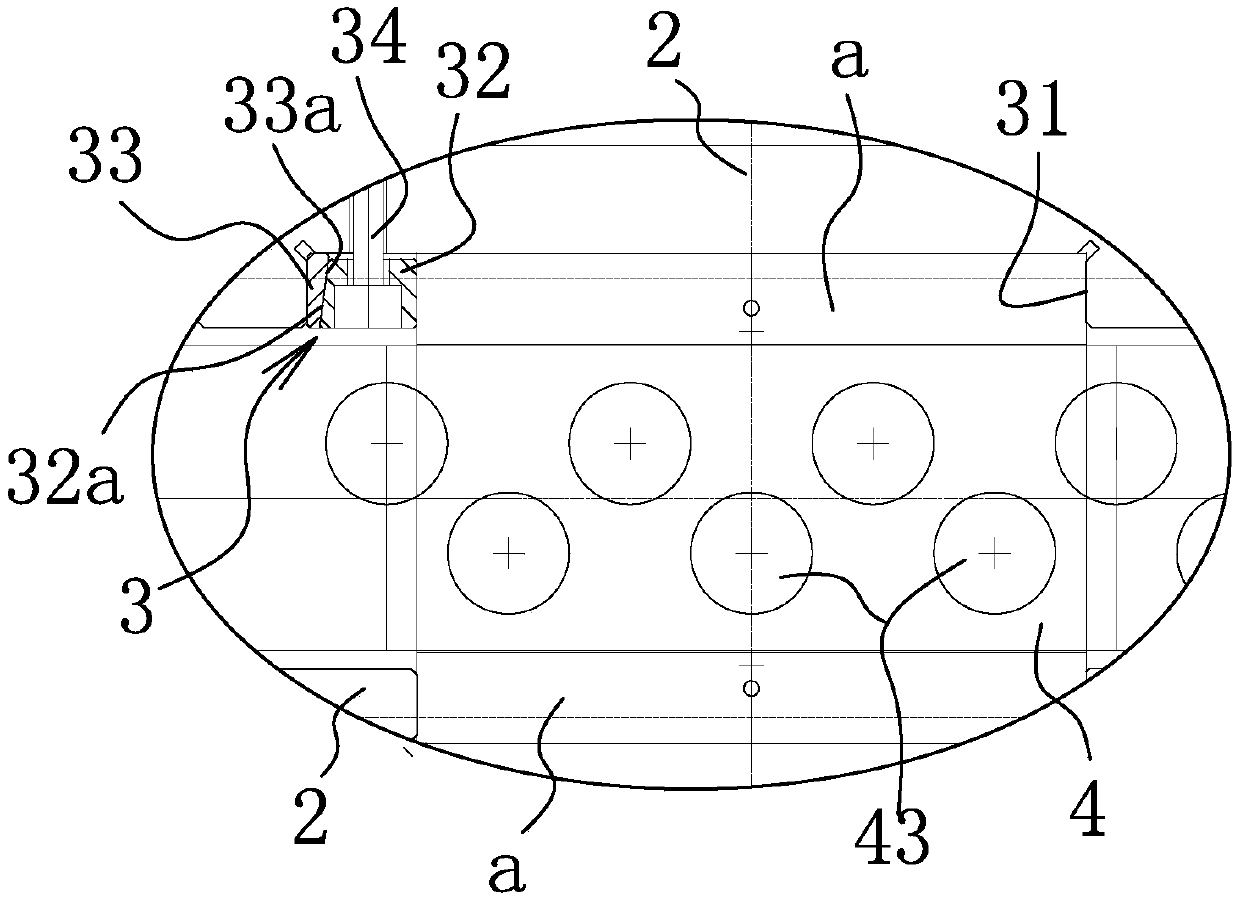

[0032] Such as Figure 1-2 As shown, the high-load anti-friction plate testing machine includes a frame-type pressure-bearing frame 1, and two symmetrically arranged anti-friction plate seats 2 are arranged in the frame-type pressure-bearing frame 1. The opposite side is respectively equipped with test friction reducing plate a through side pressure mechanism 3, such as Figure 7 As shown, the test anti-friction plate a includes a plate body. On one side of the plate body, there are several flat-bottomed blind holes and nuclear graphite columns embedded in the flat-bottomed blind holes. The outer ends of the nuclear graphite columns protrude from the plate body and have a flat bottom. side of the blind hole. Such as image 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com