Automatic clamping failure detection mechanism for automobile seat horizontal drive mechanism

A car seat and drive technology, applied in the detection field, can solve the problems of increasing the probability of product misjudgment and misreceiving, product cost increase, misjudgment of qualified products and other problems, and achieves the convenience of fault signal measurement, convenient manufacturing and operation, The effect of low technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

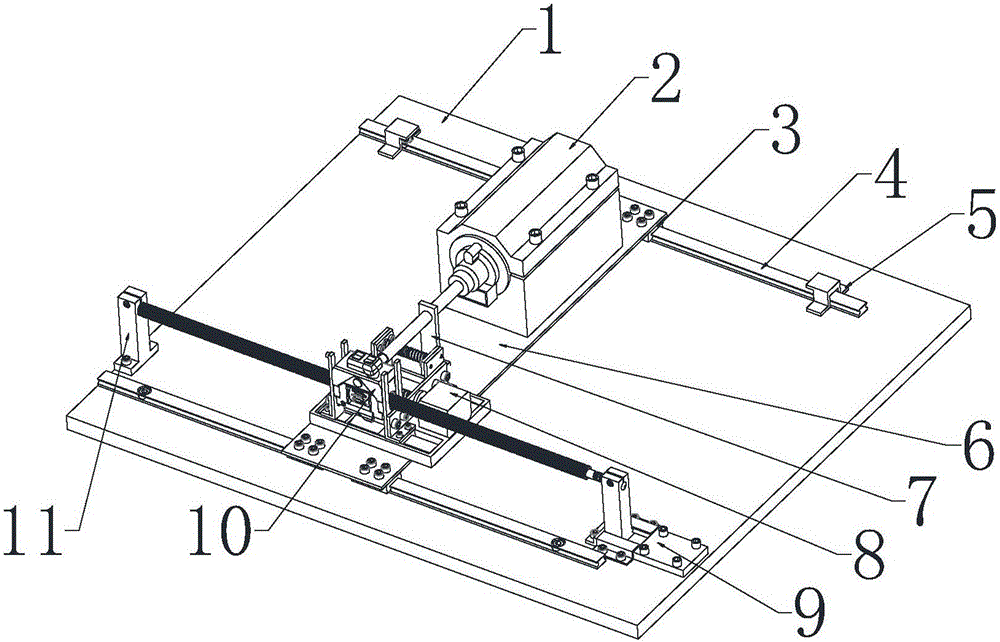

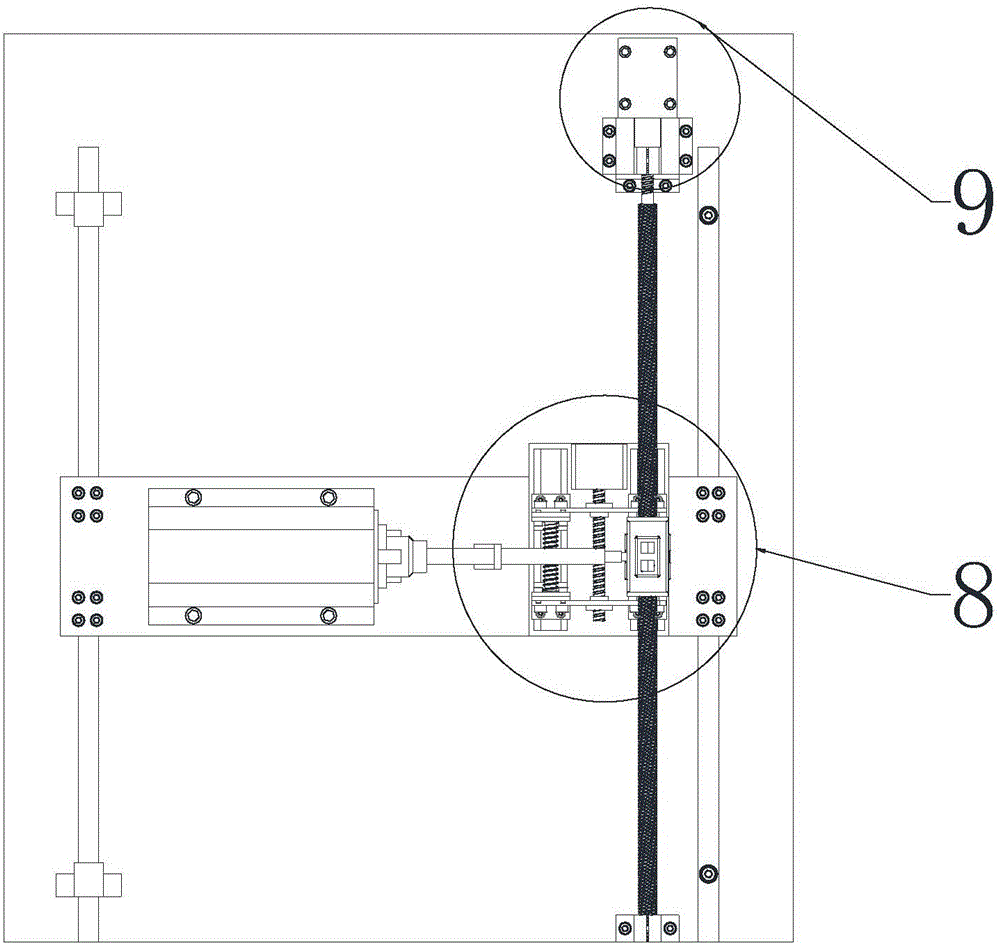

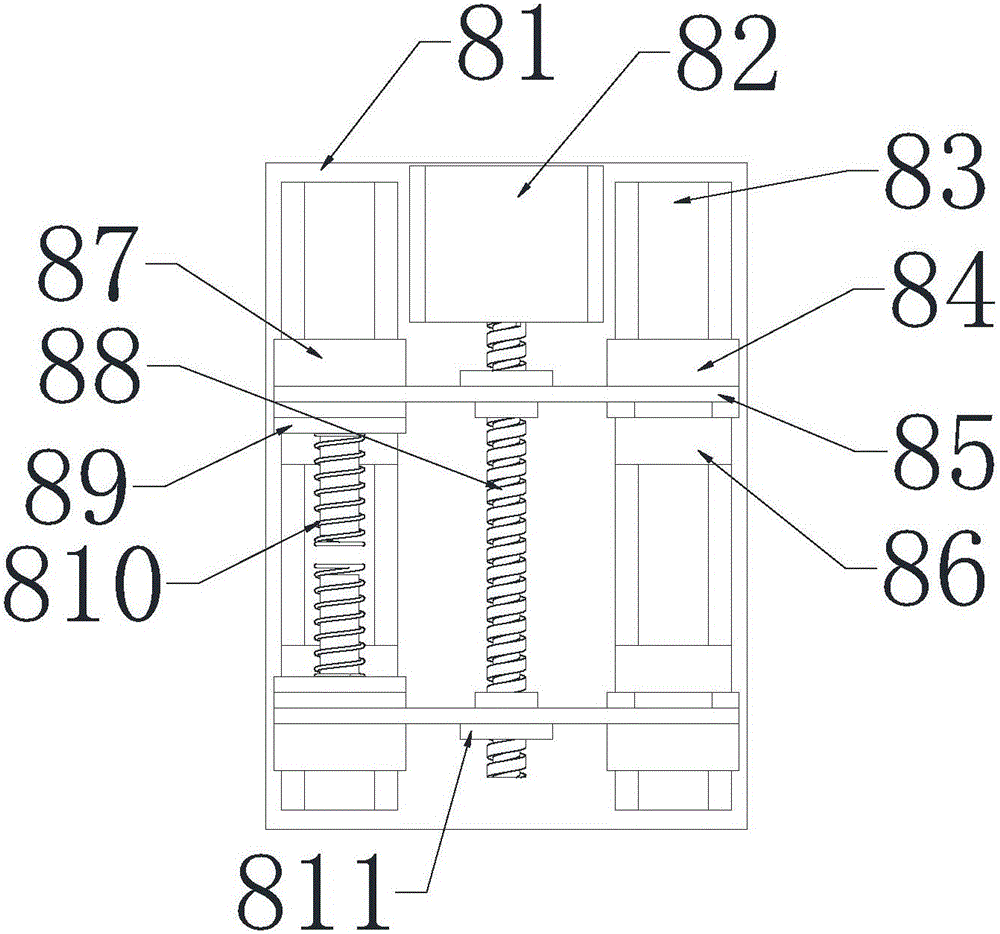

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a car seat horizontal drive automatic clamping fault detection mechanism, including mechanism base plate 1, motor mounting bracket 2, first slider 3, linear sliding guide rail 4, limit sensor 5, transmission horizontal plate 6, drive motor , Motor bushing support 7, HDM gearbox automatic clamping device 8, HDM screw automatic clamping device 9 and big head screw support 11. Two linear sliding guide rails 4 are parallelly fixed on the bottom plate 1 of the mechanism, and each linear sliding guide rail 4 forms a sliding pair with the first slider 3; each linear sliding guide rail 4 is provided with a limit sensor 5 at both ends; the transmission horizontal plate 6 The two ends of the two linear sliding guide rails 4 are fixed with the first slider 3; the motor mounting bracket 2 is fixed on the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com