Atmospheric corrosion exposed test stand

An exposure test and atmospheric corrosion technology, which is applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as inconvenient transmission line poles, test failures, and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further illustrate the atmospheric corrosion exposure test rack provided by the embodiment of the present invention, it will be described in detail below with reference to the accompanying drawings.

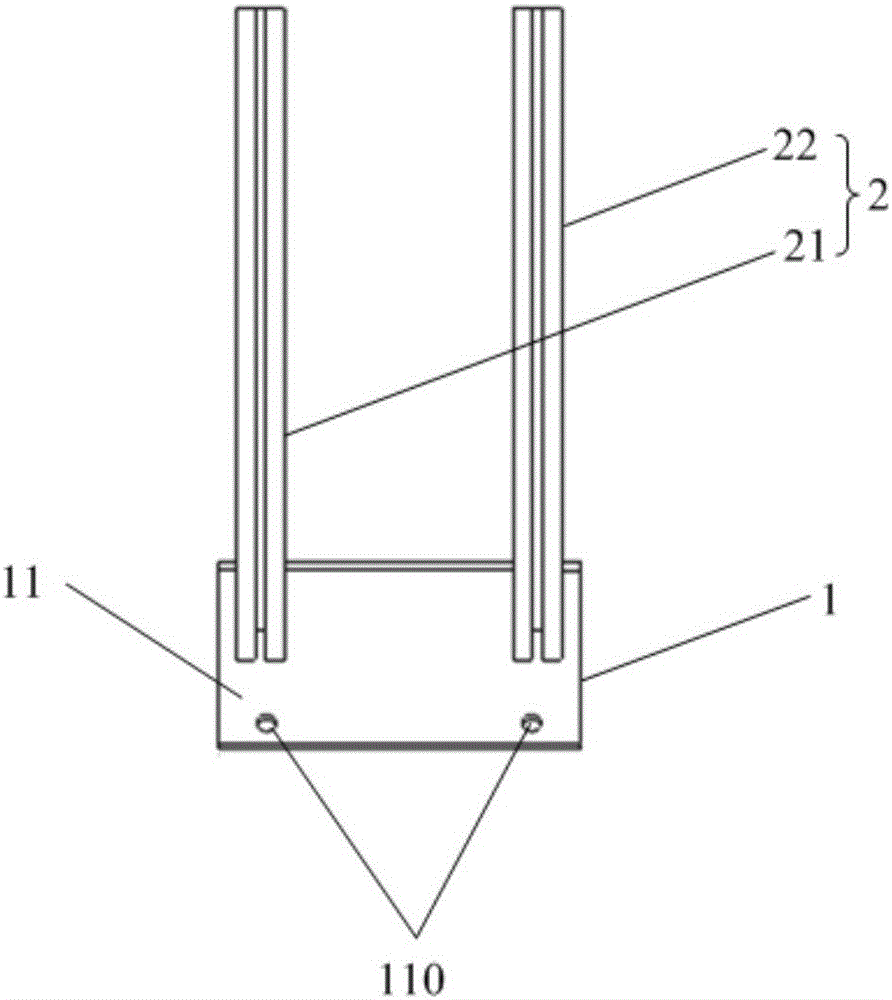

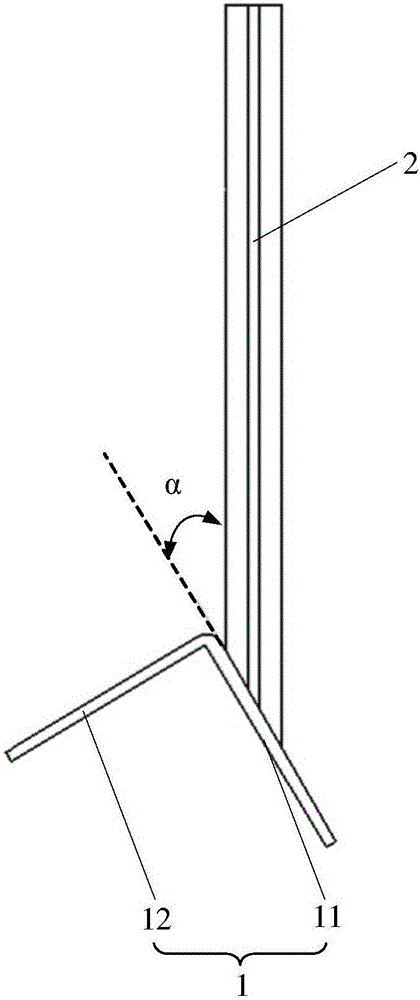

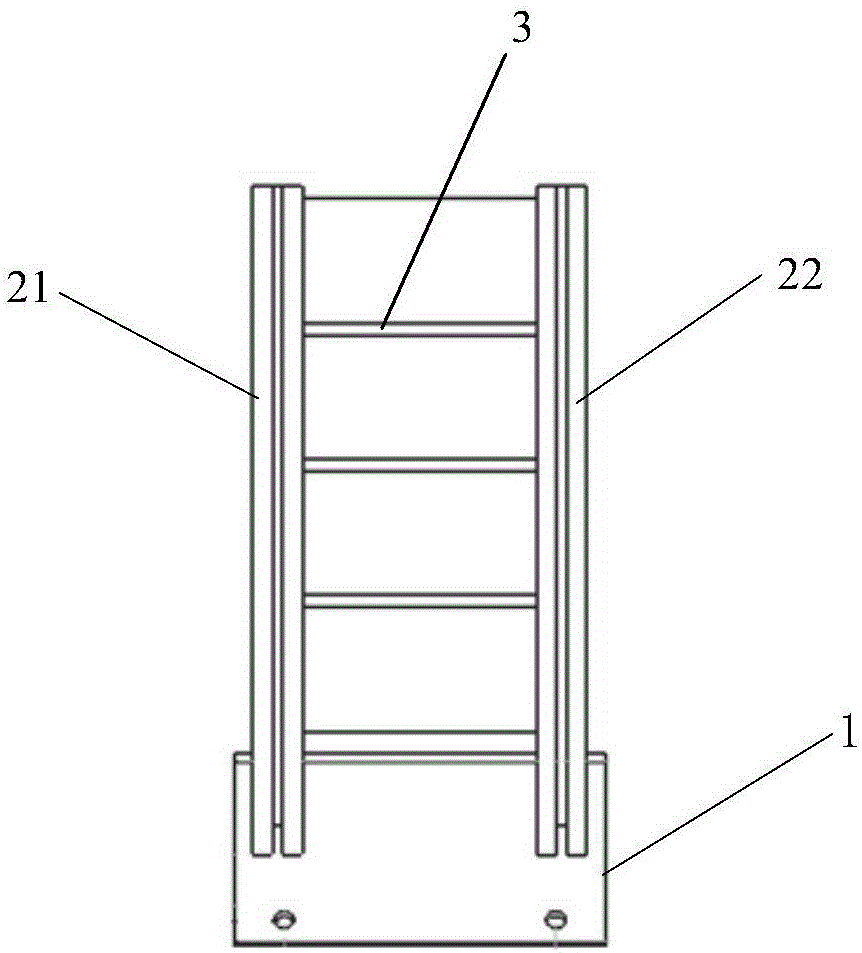

[0030] see figure 1 , the atmospheric corrosion exposure test frame provided by the embodiment of the present invention includes: a base 1, the mounting part of the base 1 is provided with a fixing frame 2 for fixing a metal test piece, the fixing frame 2 fixes the metal test piece, and the surface of the metal test piece is connected to the horizontal plane. The included angle is the test angle, and the test angle is an acute angle; the base 1 is detachably connected with a fastener that forms a clamping sleeve with the base 1, and the installation part of the building is clamped in the clamping sleeve.

[0031] The atmospheric corrosion exposure test rack provided in this embodiment can be used in various outdoor buildings requiring long-term on-site monitori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com