Rapid-positioning bending machine

A bending machine, fast technology, applied in the direction of metal processing, metal processing equipment, safety equipment, etc., can solve the problems of dead angle of sight, easy to cause accidents, poor bending quality, etc., to improve positioning accuracy, prevent safety accidents, The effect of preventing false pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

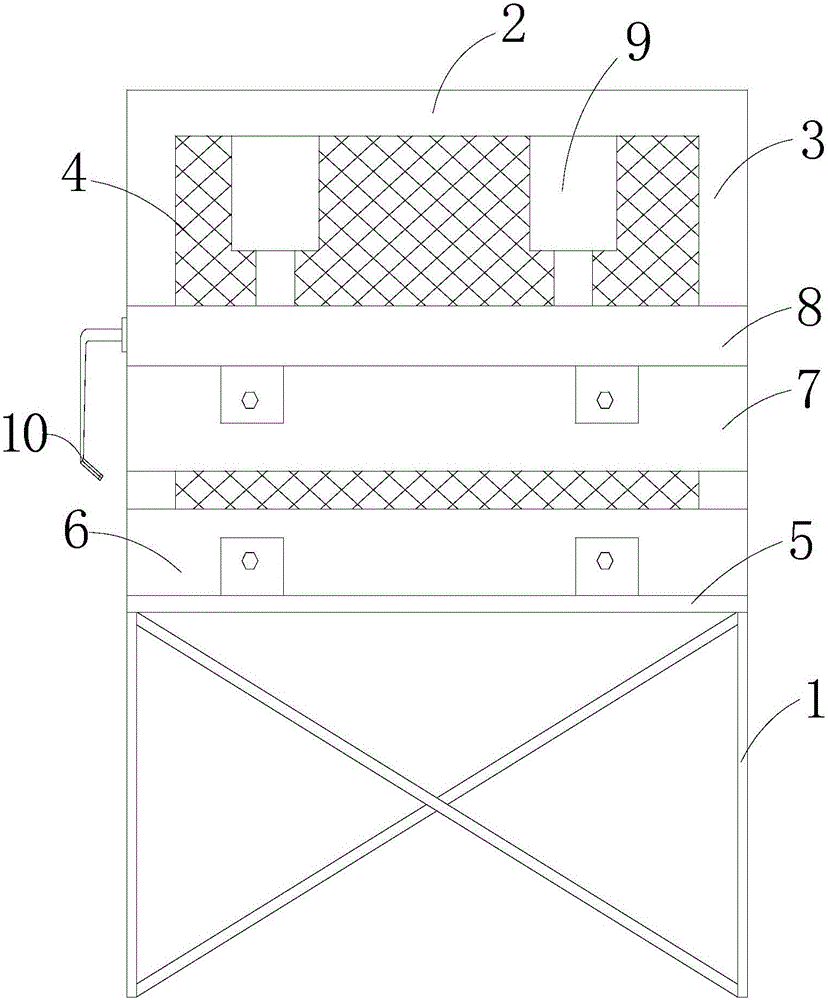

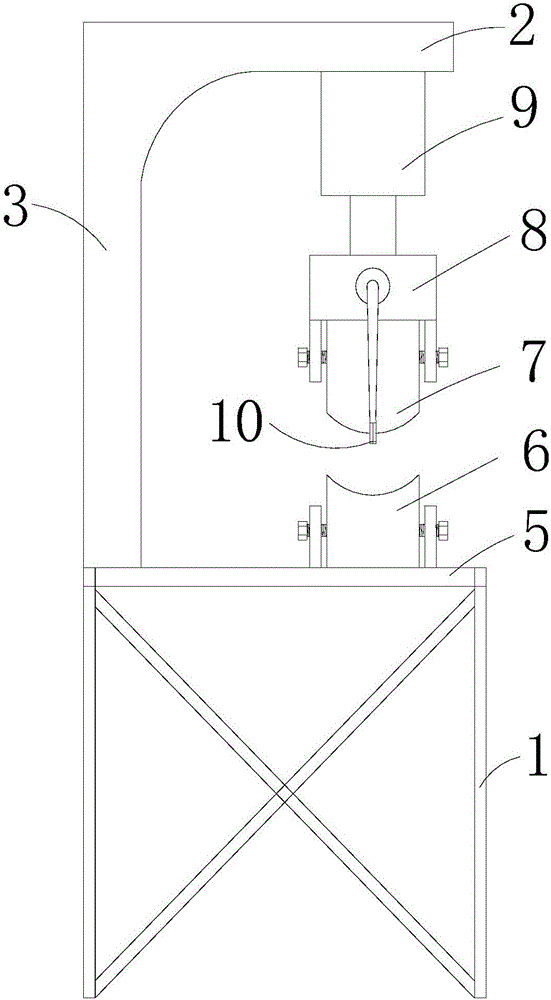

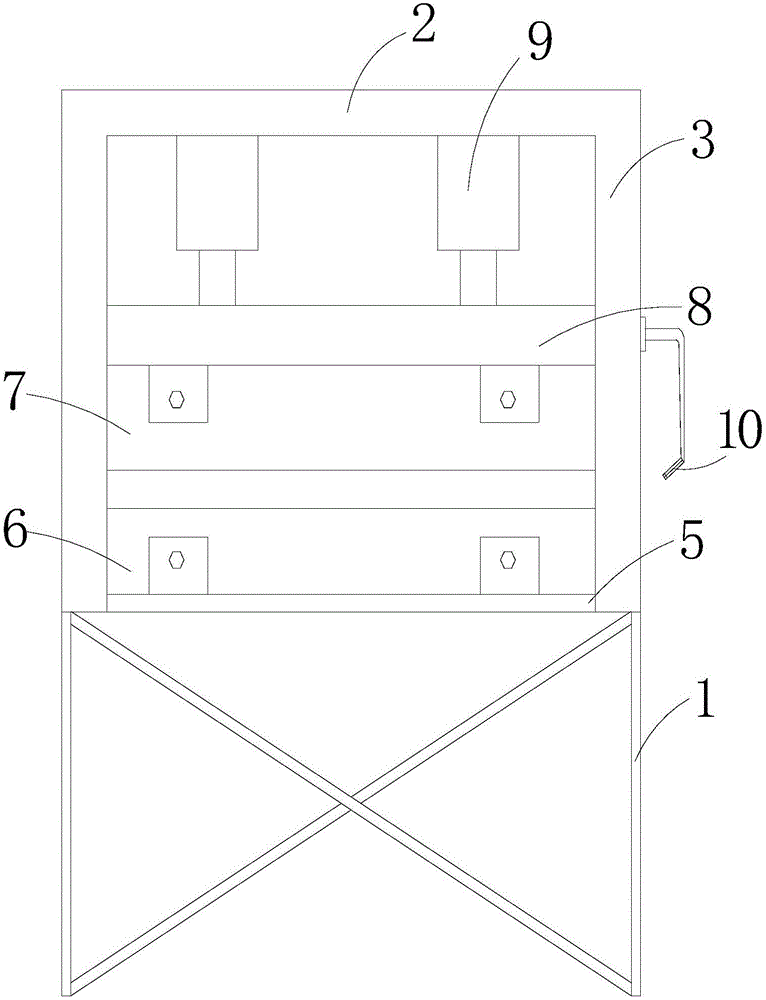

[0015] Such as Figure 1-3 As shown, the present invention provides a fast positioning bending machine, including a lower bracket and an upper bracket. The upper bracket is fixedly connected to the upper side of the lower bracket through a column. There are two columns, and a protective net is installed between the columns. A bending platform is installed on the surface. The upper surface of the bending platform is fixed with a lower bending die by bolts. The upper bending die is equipped with a bending upper die that is compatible with the lower bending die. The head is fixedly connected, and the pressure head is installed at the lower part of the upper bracket through a hydraulic device, which prevents unrelated persons from extending their hands or other irrele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com