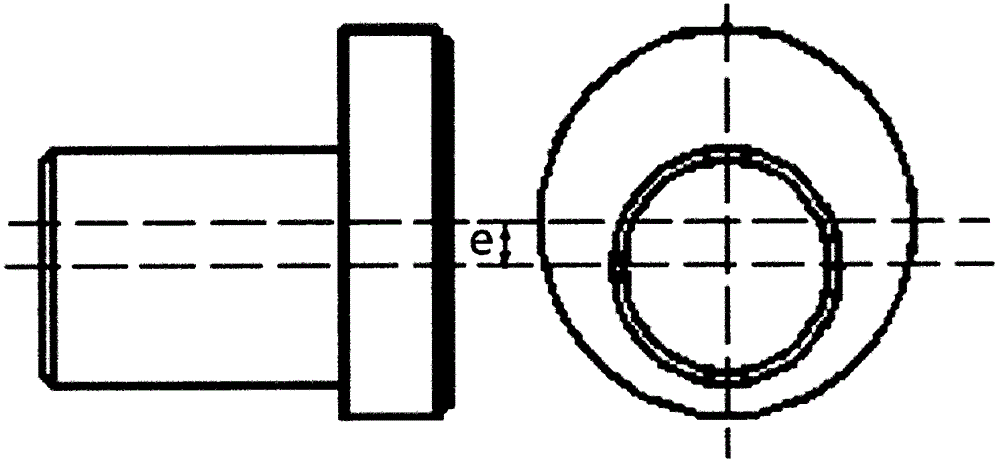

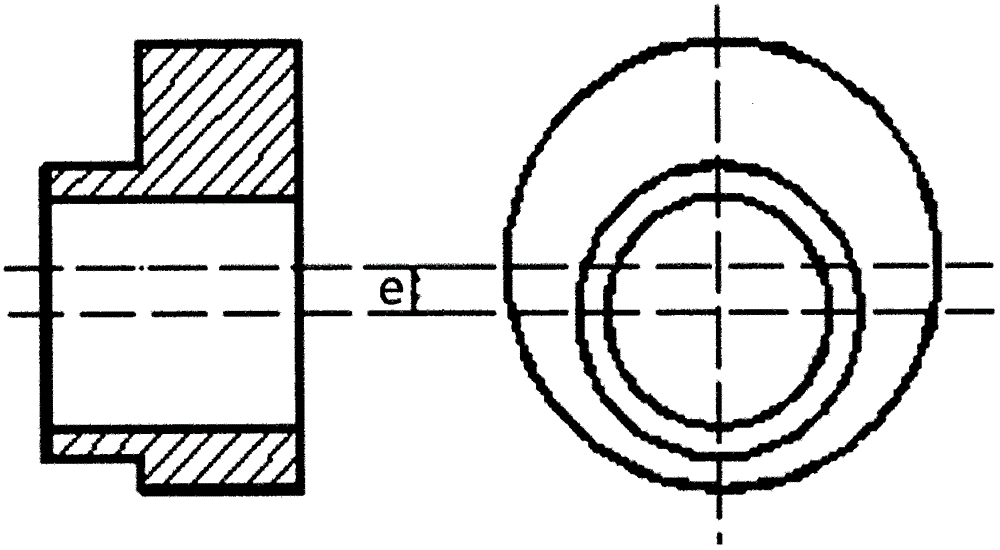

Adjustable eccentric chuck

A technology of eccentric chucks and chucks, applied in the direction of chucks, etc., can solve the problems of low precision of eccentric parts, inconvenient processing and use, etc., and achieve the effect of strong versatility, convenient adjustment and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

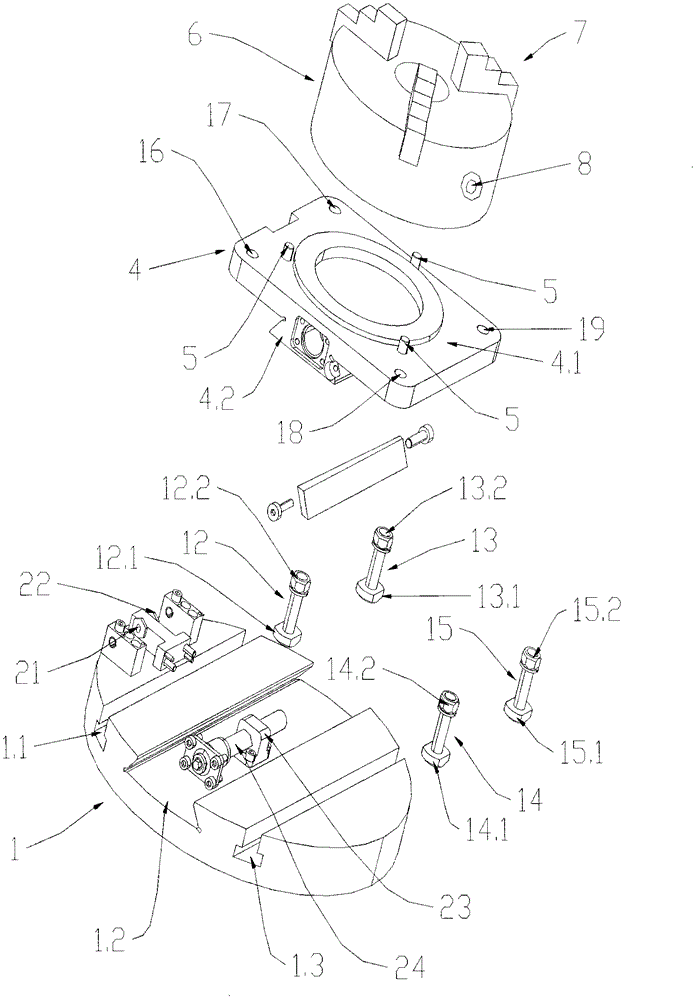

[0033] Such as image 3 , 4 , 5, and 6, the adjustable eccentric chuck of this embodiment includes a transition plate 1 fixed to the connecting plate of the lathe spindle with stud bolts, a gap adjustment mechanism 2, an eccentricity adjustment mechanism 3, a slider seat 4, two pairs of Locking bolts, screws 5, chuck body 6, jaws 7, jaw adjustment holes 8, measurement support 9 and a pair of measurement stops 10, 11; the transition plate is provided with a first T-shaped groove 1.1, a dovetail Slot 1.2, second T-shaped slot 1.3; the upper part 4.1 of the slider seat 4 is connected to the chuck body 6 through the screw 5, and the dovetail guide rail 4.2 at the lower part of the slider seat 4 cooperates with the dovetail groove 1.2 , the T-shaped ends 12.1, 13.1; 14.1, 15.1 of each pair of locking bolts 12, 13; The connection ends 12.2, 13.2, 14.2, 15.2 of , 14, 15 are fixedly connected to the connection holes 16, 17, 18, 19 of the slider seat 4 respectively; the ring grooves ...

Embodiment 2

[0043] Such as Figure 7 As shown, the second embodiment is basically the same as the first embodiment, the difference is that the workpiece contact surface 7.11 of the first jaw 7.1 in this embodiment is a plane; the second jaw 7.2 and the third jaw 7.3 The workpiece contact surfaces 7.12, 7.13 are right angle structures. Friction surfaces are provided on the plane and right-angle structures. The friction surface is several convex lines.

[0044] The embodiment of the present invention assists the up and down centering and clamping of the square workpiece, the first jaw 7.1 workpiece contact surface 7.11 presses the upper part of the square workpiece firmly, the second jaw and the third jaw right-angle workpiece contact surfaces 7.12 and 7.13 are opposite to each other After centering and clamping the shaped workpiece, it can be processed and turned. It is suitable for medium batch single and two-way eccentric square workpieces.

Embodiment 3

[0046] Such as Figure 8 As shown, the third embodiment is basically the same as the first embodiment, the difference is that an alarm device 100 is also provided on the chuck body 6 in this embodiment, and the alarm device includes an alarm 101, a battery 102 , the first contact piece 103 and the second contact piece 104; the first contact piece 103 and the second contact piece 104 are respectively arranged on the claw adjustment hole 8, and the first contact piece 103 is connected to the A battery 102, the battery provides power for the alarm through wires, the battery 102 is connected to the alarm 101, and the alarm is used to send out alarm reminders, and the alarm 101 is connected to the second contact piece 104 through wires. The above-mentioned first contact piece 103 and second contact piece 104 are not connected with the chuck body 6 .

[0047] The embodiment of the present invention prevents the occurrence of major safety accidents by setting an alarm device, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com