Multi-tool path layered and adjustable milling cutter

A technology for milling cutters and tool paths, which is applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of inability to realize continuous processing and low efficiency, and achieve the effects of saving time, labor and resources, improving efficiency, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] The present invention will be further explained below in conjunction with the drawings.

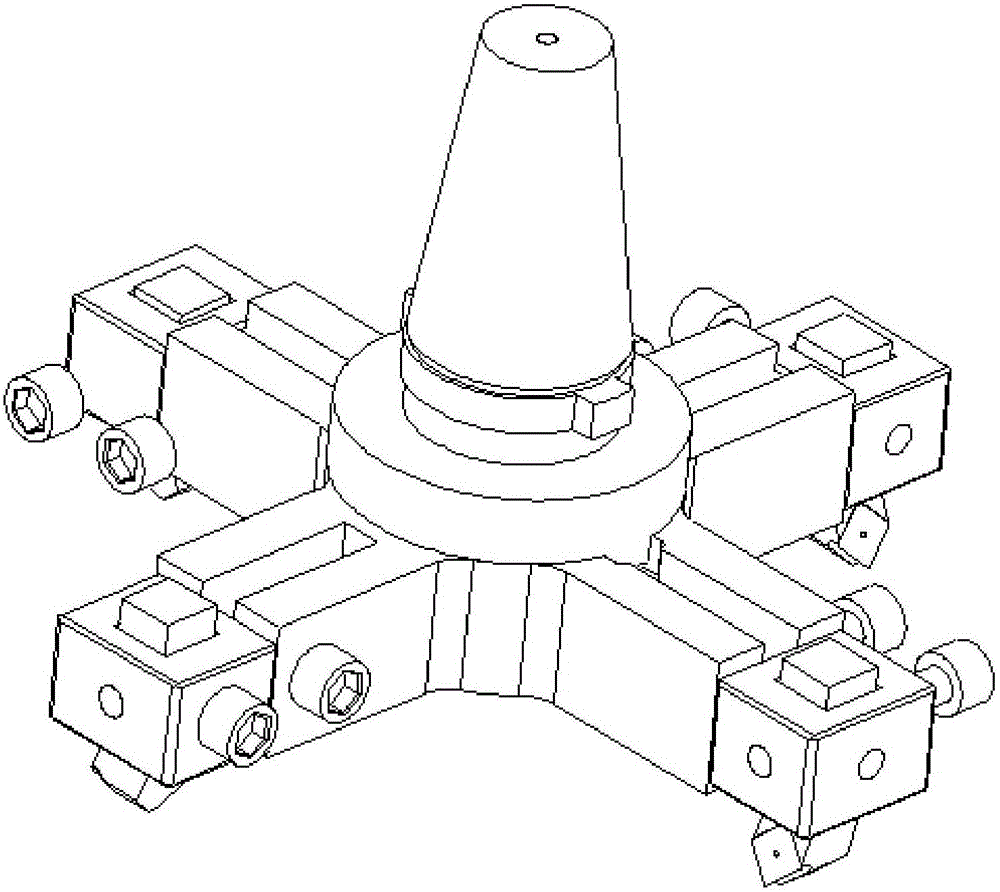

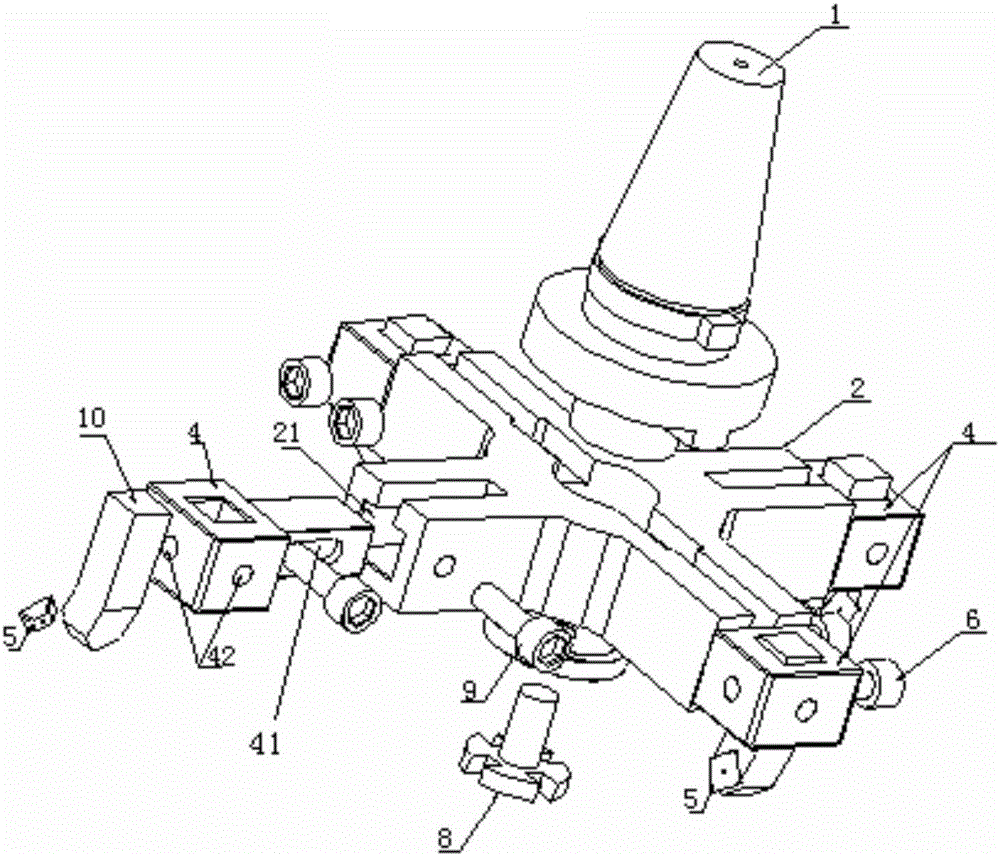

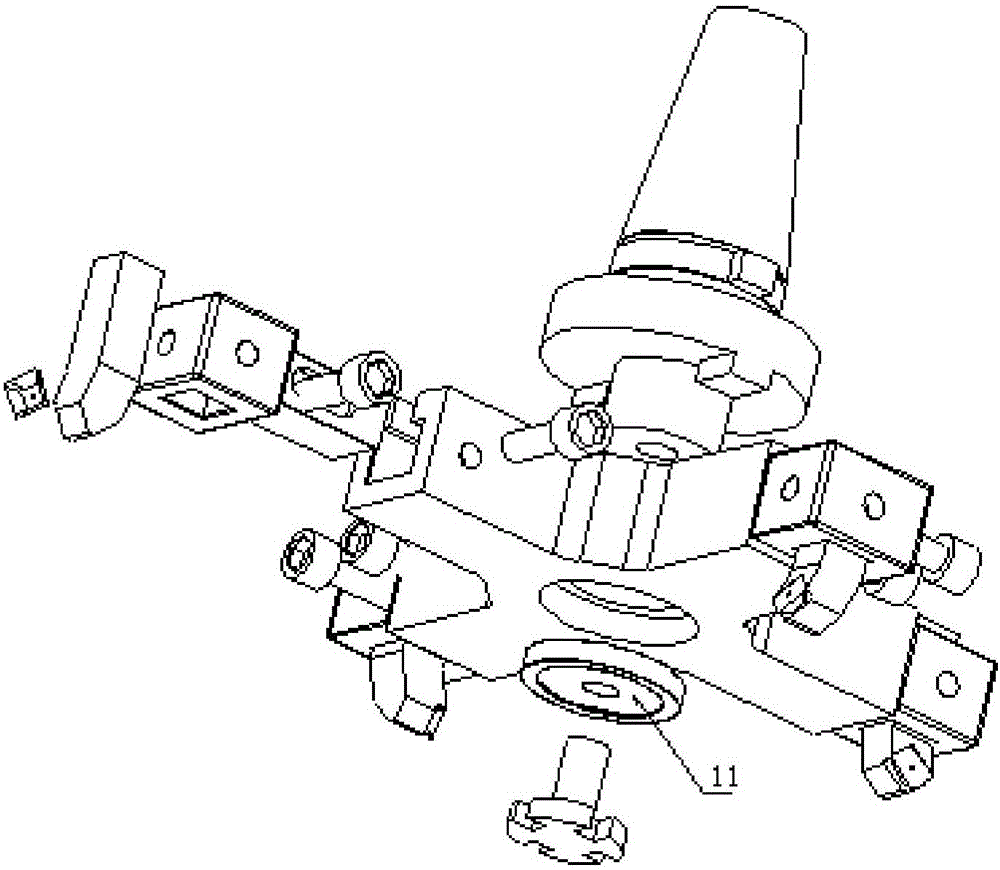

[0023] see figure 1 , figure 2 , image 3 , This embodiment is an example of installing four knives in the present invention:

[0024] In the figure, 1 is the chuck, 2 is the sliding support of the knife holder, 3 is the knife body 1, 4 is the knife holder, 5 is the blade, 6 is the fastening screw, 8 is the chuck screw, 9 is the safety screw, 11 is In the gasket, 21 is an adjustment groove, 41 is a safety groove, 22 is a safety hole, and 42 is a fastening screw hole.

[0025] The chuck 1 is tightly connected with the tool holder sliding support 2 through the gasket 11 and the chuck screw 8. The chuck 1 is connected with the machine tool spindle. The rotation of the spindle drives the chuck 1 to run at high speed, and the chuck 1 transmits the transmission through the keyway connection To the carriage sliding support 2. Each cutter body 1 has the same shape, material, and size. The cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com