Complete equipment of welding robot and welding jig

A welding robot, welding fixture technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of good mobility, high repeat positioning accuracy, and fast welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

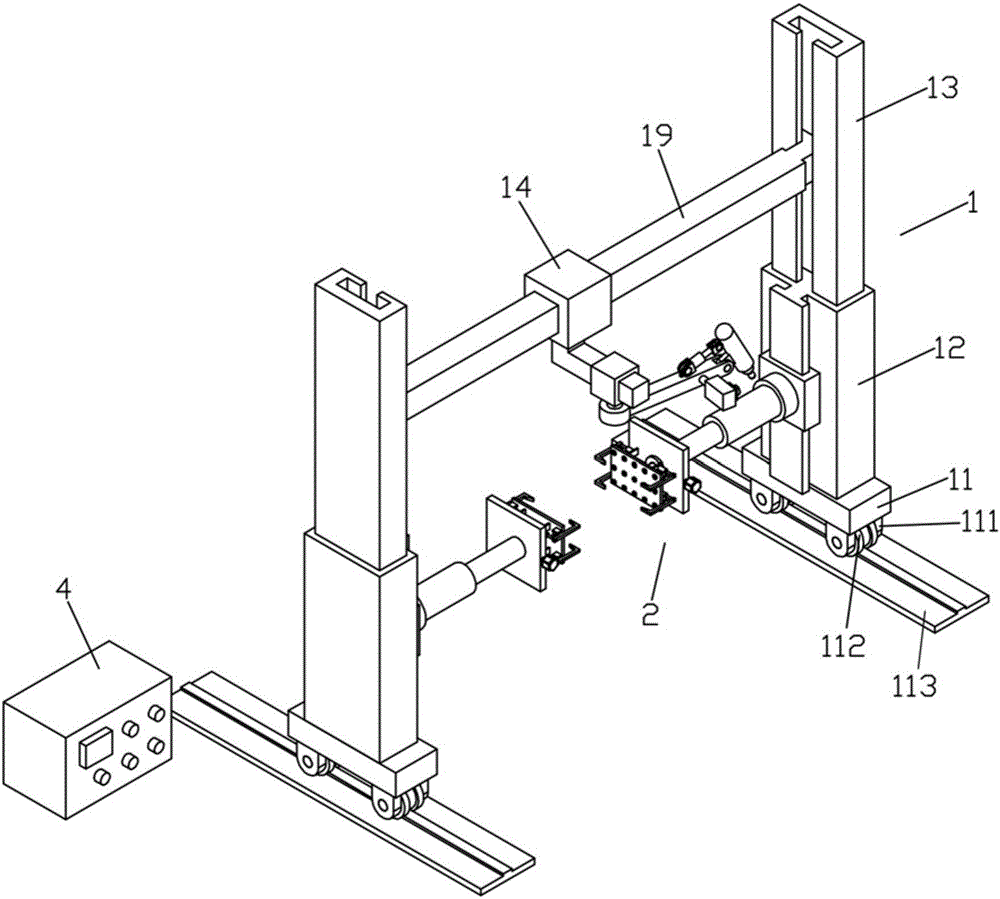

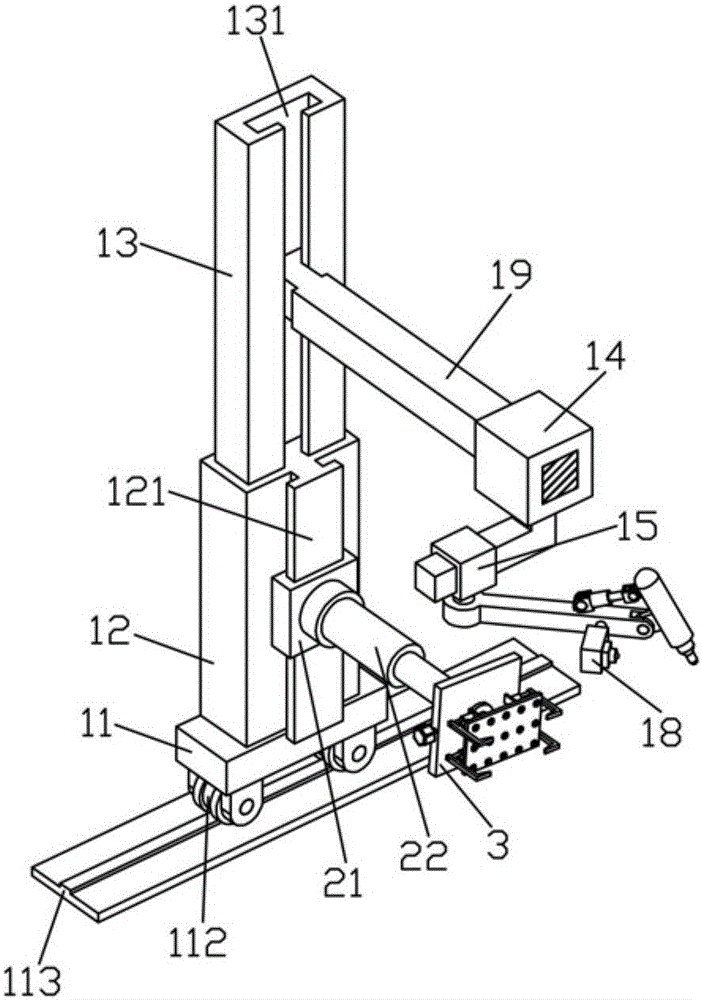

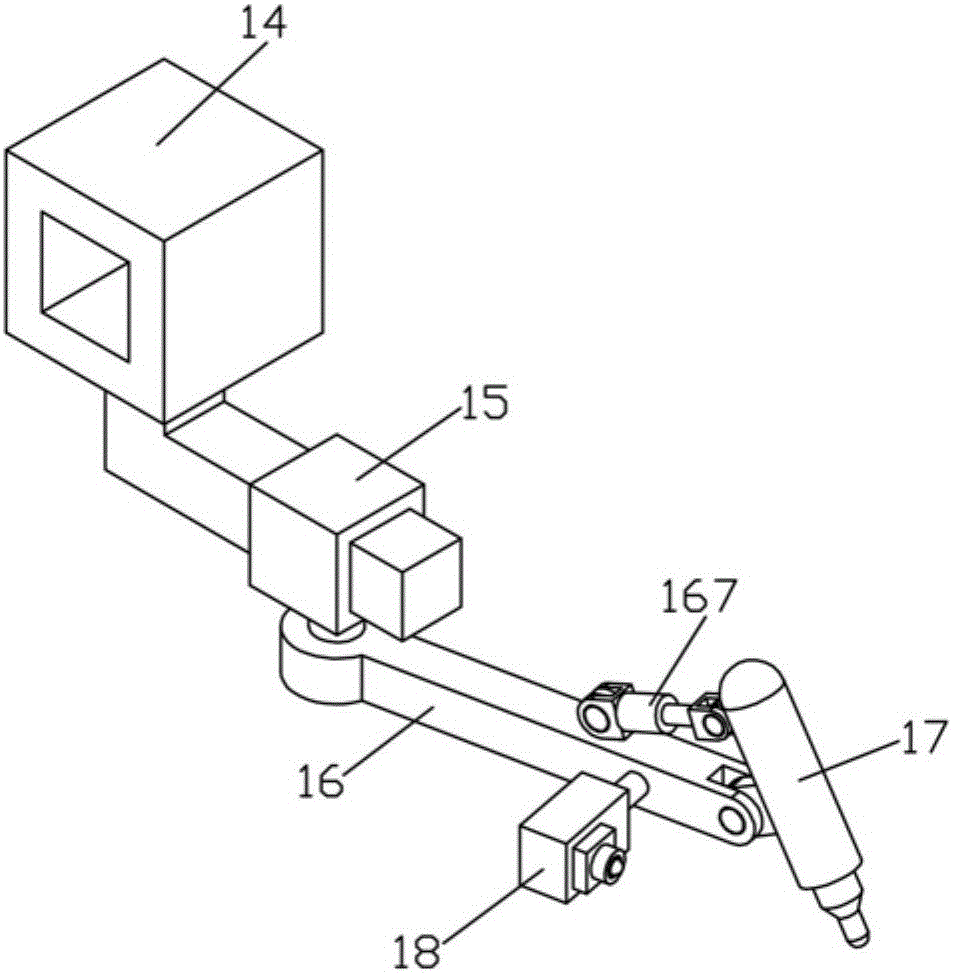

[0020] Such as figure 1 As shown, the welding robot and welding fixture complete set of equipment 1 includes a multi-degree-of-freedom welding manipulator assembly, a CCD camera 18, a welding fixture 2, and a control box 4. Electrical connection, the control box 4 is located on the side of the welding fixture, the multi-degree-of-freedom welding manipulator assembly is located in the middle above the welding fixture, the CCD camera 18 is located on the multi-degree-of-freedom welding manipulator assembly, the control box 4 includes a host computer and a PLC controller, and the PLC control The device constantly controls the action of the multi-degree-of-freedom welding manipulator assembly and the welding fixture 2. During the welding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com