Omni-directional water conservancy steel pipe mounting robot

A robot and all-round technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of difficult access of wheeled vehicles, low efficiency of handling and stacking, dangerous safety accidents, etc., and achieve high cost and convenient grabbing and stacking Fast, highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

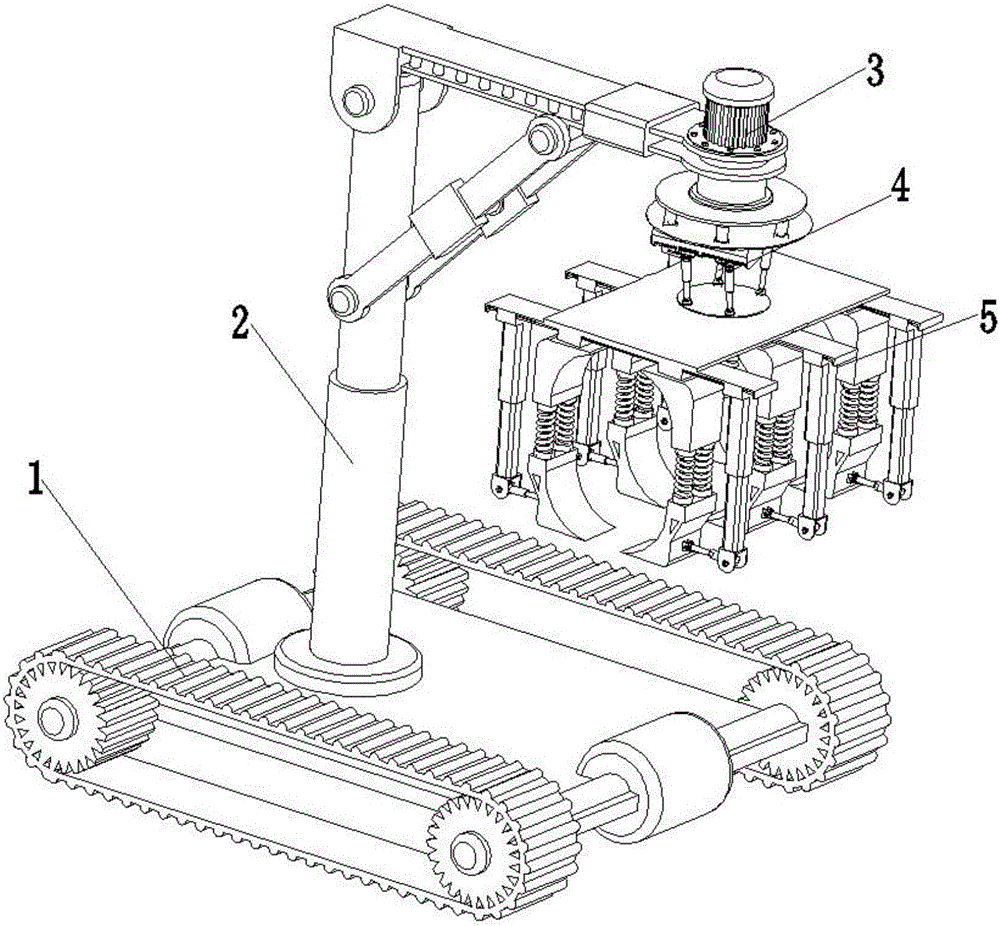

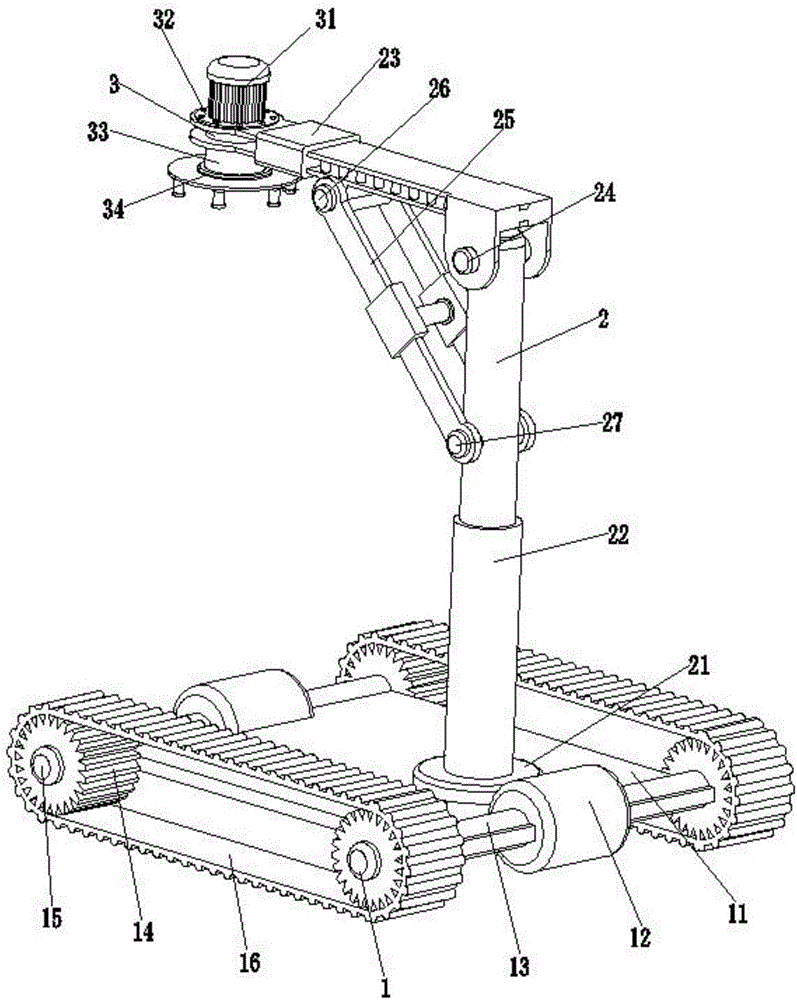

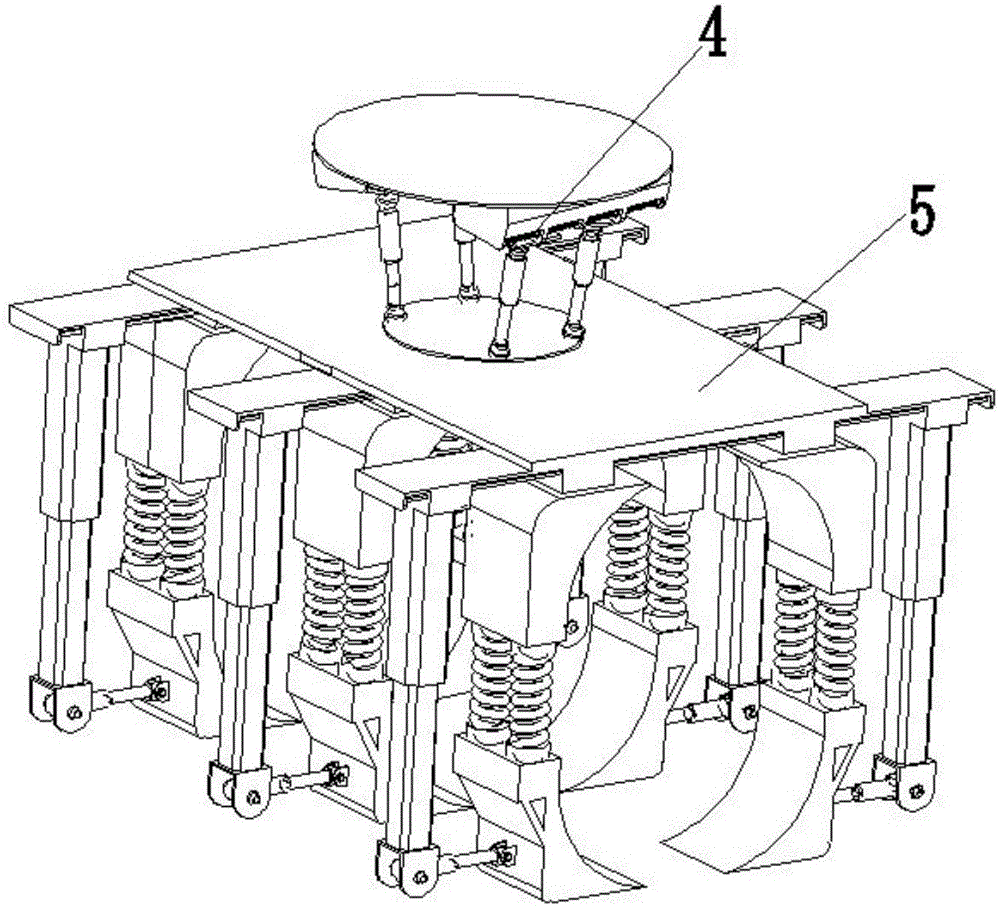

[0026] Such as Figure 1 to Figure 6 As shown, an all-round water conservancy steel pipe installation robot includes a walking device 1, an adjustable bracket 2, a rotating device 3, a hybrid mechanism 4 and a clamping device 5; The rotating device 3 is located at the front end of the adjustable bracket 2, and the rotating device 3 is fixedly connected with the adjustable bracket 2, the hybrid mechanism 4 is located between the rotating device 3 and the clamping device 5, and the upper end of the hybrid mechanism 4 is connected to the rotating device 3 The lower end of the hybrid mechanism 4 is connected with the clamping device 5 .

[0027] Such as figure 2 As shown, the walking device 1 includes a chassis 11, a drive motor 12, a drive shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com