Sheet grasping hand

A technology for grasping hands and sheets, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of unstable shape, difficult grasping, fluffy LWRT material structure, etc., and achieve the effect of firm grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

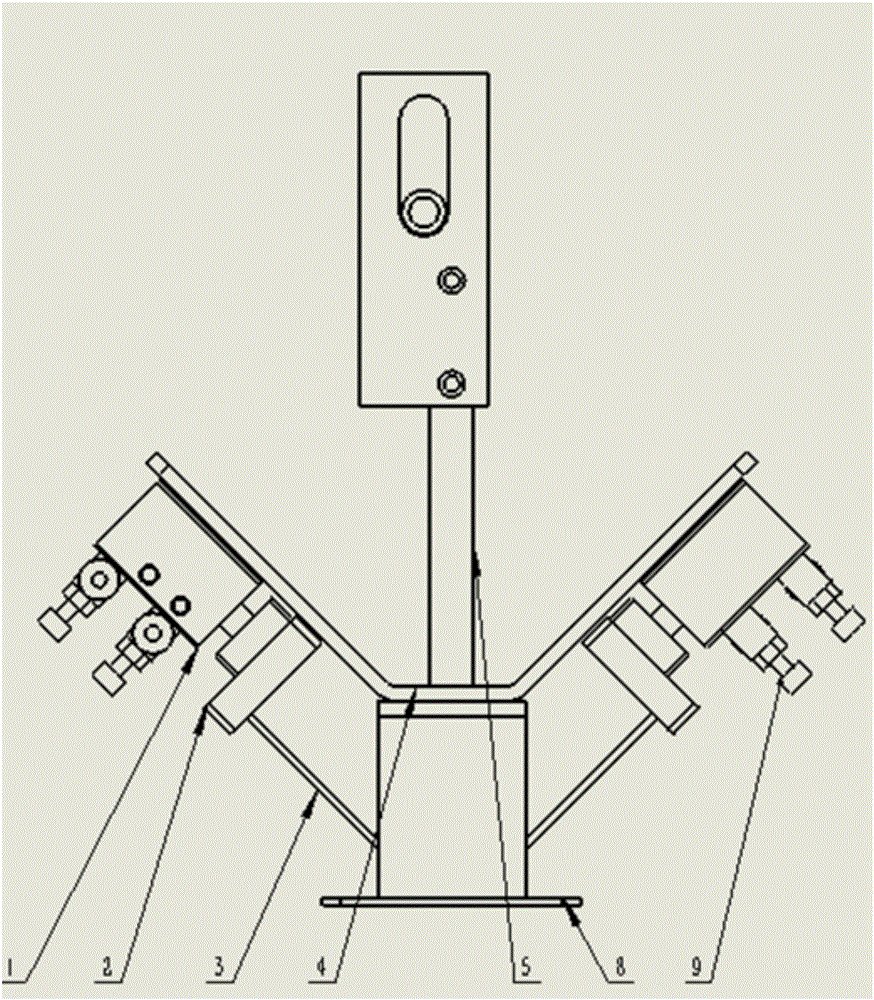

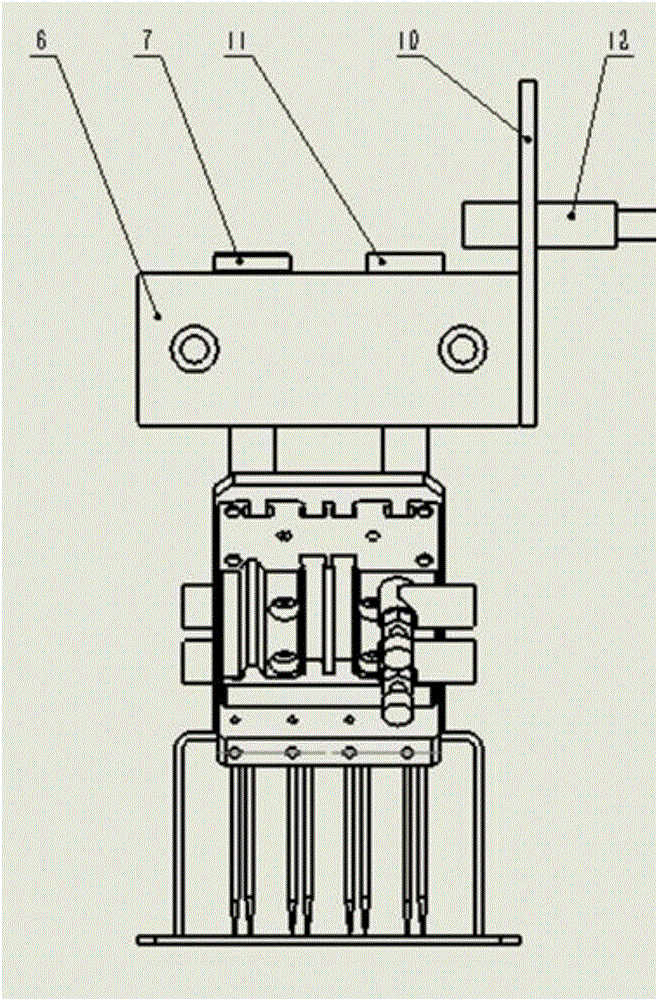

[0020] Such as figure 1 , 2 As shown, the sheet material grasping hand includes a hand grasping mounting seat 6, a floating guide rod 5 arranged on the hand grasping mounting seat, a cylinder fixing plate 4 arranged at the bottom end of the floating guide rod, and a cylinder fixing plate connected to and located at the bottom of the floating guide rod. The lower pressing plate 8 below the cylinder fixed plate; the cylinder 1 is fixed on the fixed plate of the cylinder, the piston rod of the cylinder is connected with the steel needle mounting plate 2, and the steel needle group 3 is installed on the steel needle mounting plate, so The needle head of the steel needle group faces the lower pressing plate.

[0021] When grabbing the LWRT sheet through the above-mentioned device, the traditional manipulator is used to grab the grip mounting seat, and then the manipulator drives the present invention to move downward. Descending, the device of the present invention continues to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com