A production line diversion device

A diverting device and production line technology, applied in transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of large surface friction, unsuitable separation device, small size, etc., and achieve reliable diversion, protection integrity, and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

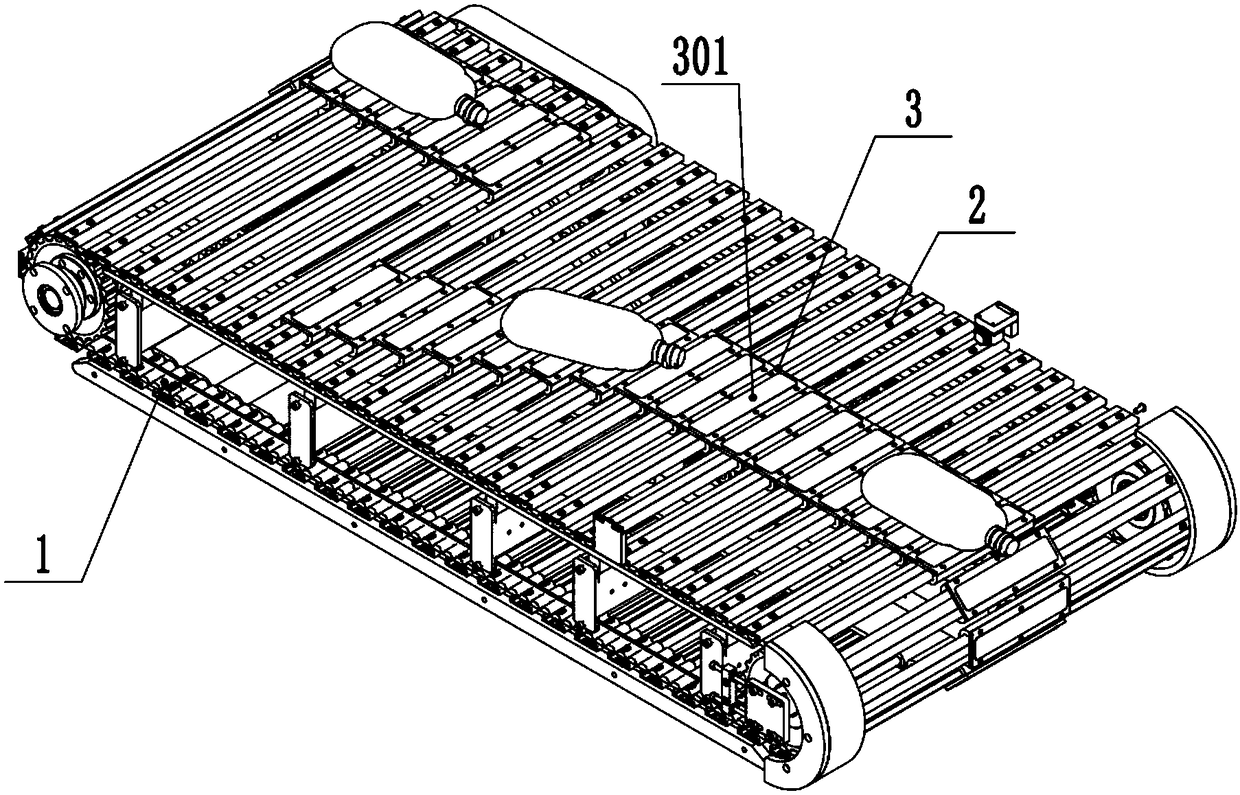

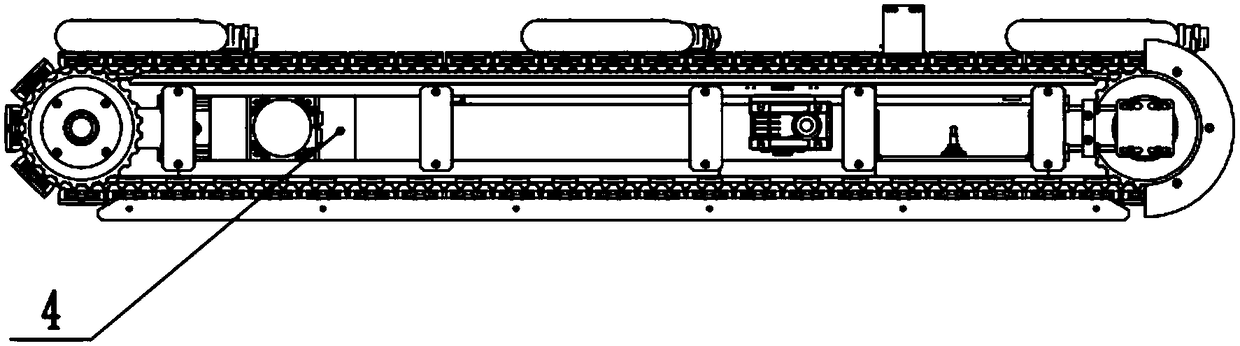

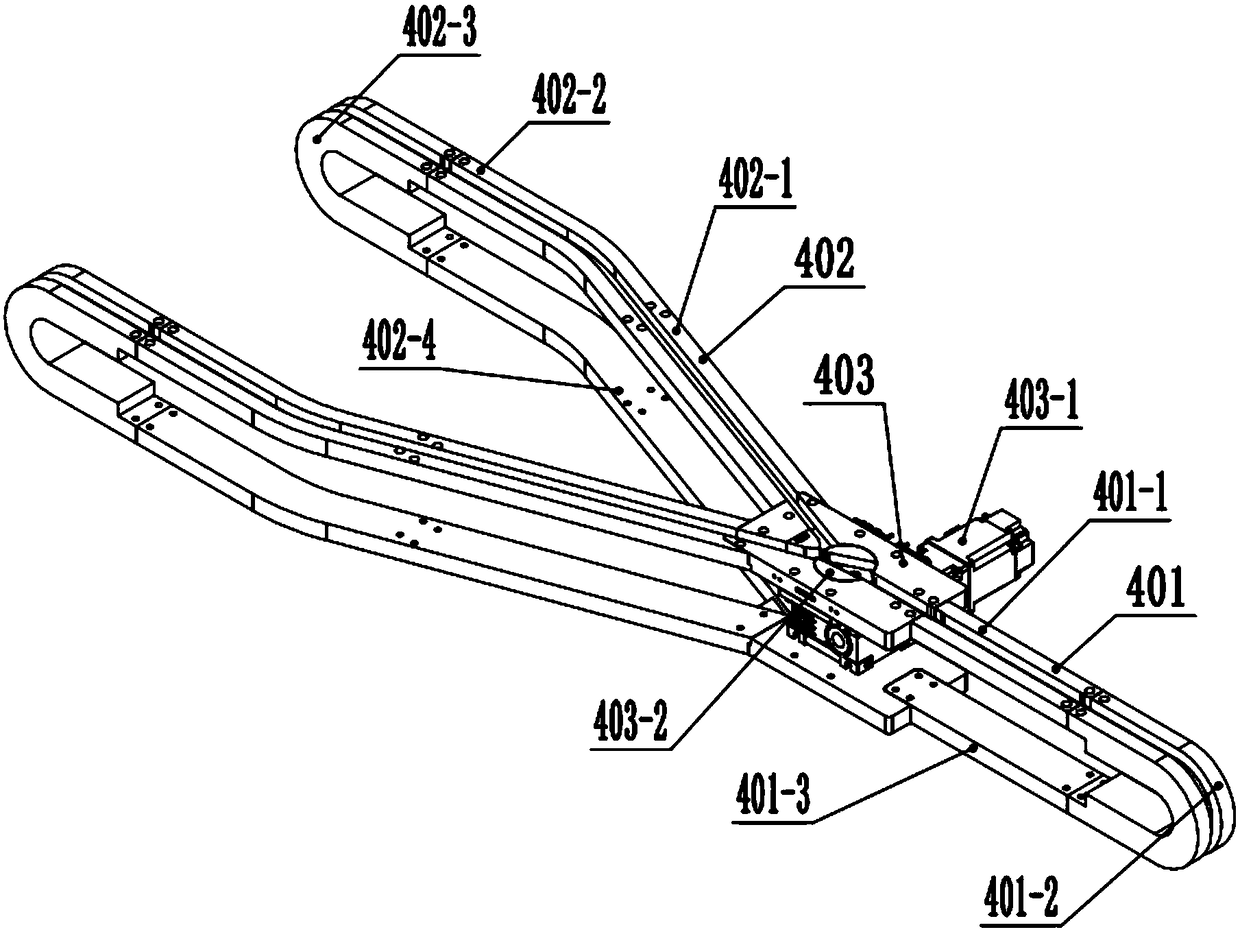

[0019] as attached figure 1 with attached figure 2 As shown, the distribution device of the production line includes two flexible circulation transmission devices 1 arranged in parallel, and the flexible circulation transmission devices 1 are belts, conveyor chains or synchronous toothed belts. A horizontal bar 2 spanning between two flexible circulating transmission devices 1 is arranged in an equidistant array around the flexible circulating transmission device 1, and a sliding block 3 is arranged on each horizontal bar 2, and each sliding block 3 are provided with a friction surface 301, the friction surface 301 is composed of a layer of rubber attached to the surface of the sliding block 3, sliding fit between the sliding block 3 and the horizontal bar 2, the sliding direction is perpendicular to the flexible The transmission direction of the transmission device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com