Cutting fluid waste liquid filtration sterilization deodorization regeneration equipment

A technology for cutting fluid and waste fluid, applied in filtration treatment, sterilization/microdynamic water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as complicated procedures, high cost, and increased production cost, and achieve High adsorption efficiency, improved service life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

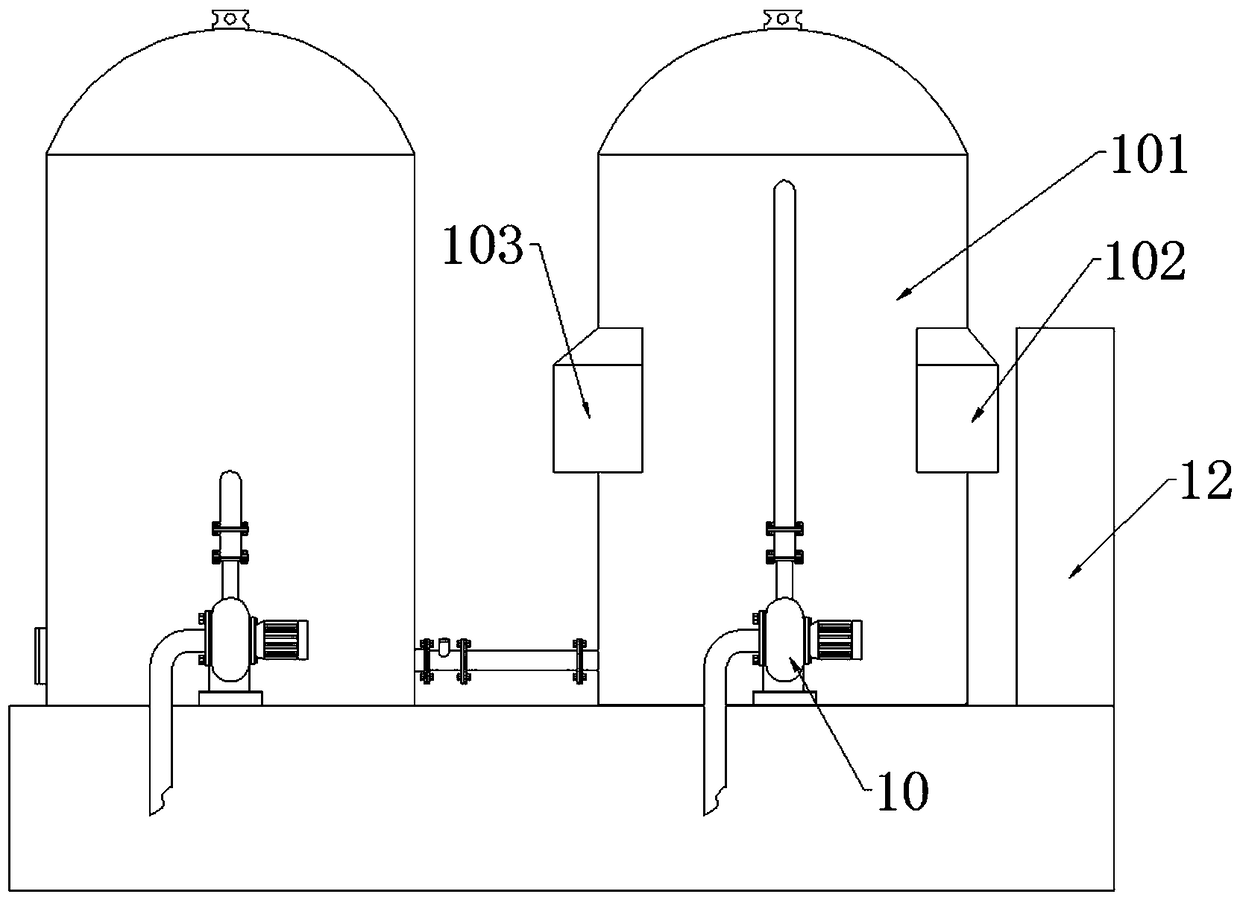

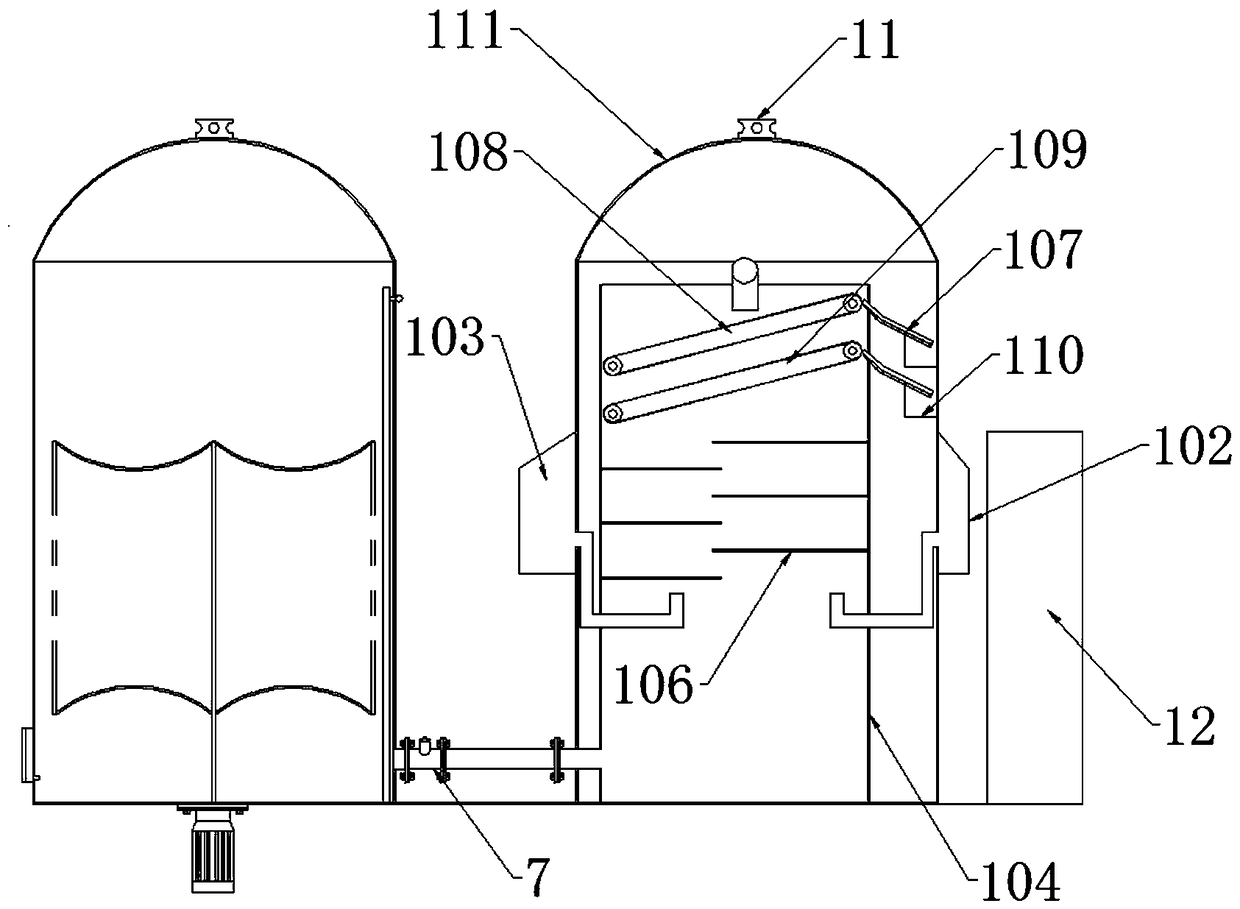

[0025] A cutting fluid waste liquid filtration sterilization deodorization regeneration equipment, see Figure 1-10 : comprising reaction kettle 101, inner tank 104, viscous adsorption collection device, metal adsorption collection device 108, reflux device, pump body, it is characterized in that: reaction kettle 101 inner cavity is provided with inner tank 104, and inner tank 104 inner cavity is from From top to bottom, a metal adsorption collection device 108, a sticky matter adsorption collection device 109 and a reflux device are arranged in sequence;

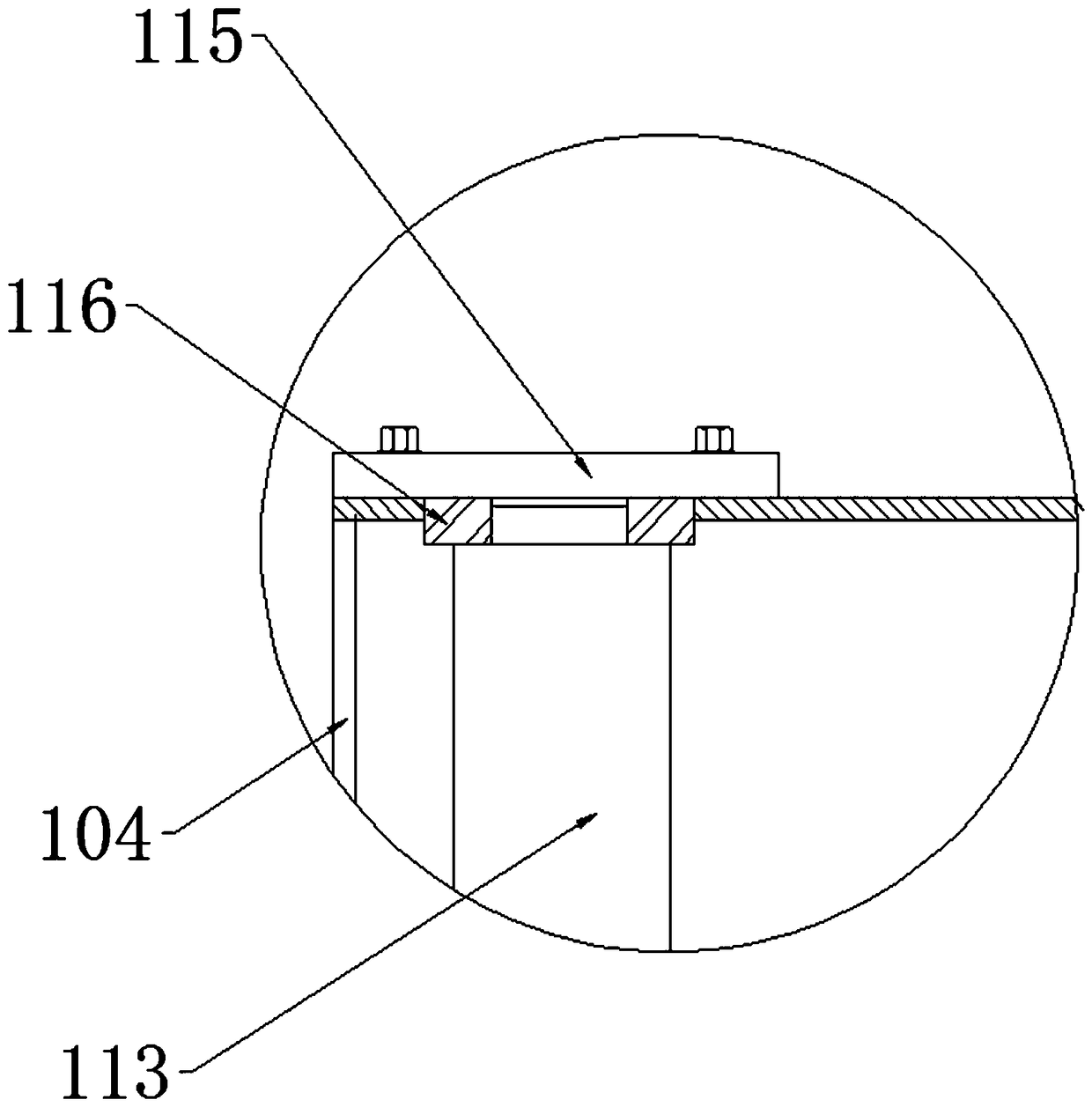

[0026] The metal adsorption collecting device 108 comprises a metal adsorption conveying device and a scraper 107, two supporting rollers 113 corresponding to each other are installed in cooperation with a magnetic conveying belt 112 to form a metal adsorbing conveying device, and the magnetic conveying belt 112 is provided with filter holes; one of the supporting rollers 113 Correspondingly connected to the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com