Cyclic cutting fluid regeneration and supplementation system

A replenishment system and liquid circulation technology, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problem that the quality of cutting fluid and the amount of liquid injection can not be well guaranteed, and it is easy to be subject to subjective factors of operators Influence, low degree of automation and other issues, to achieve the effect of simple structure, improved service life, and strong degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

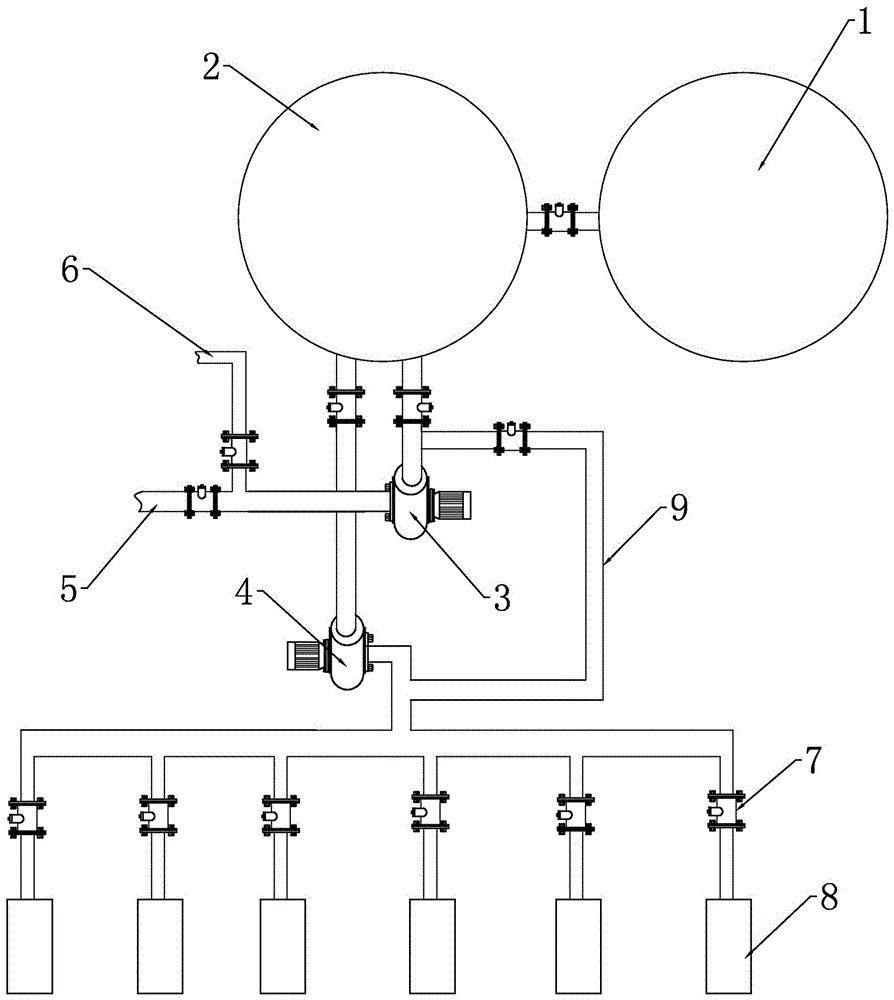

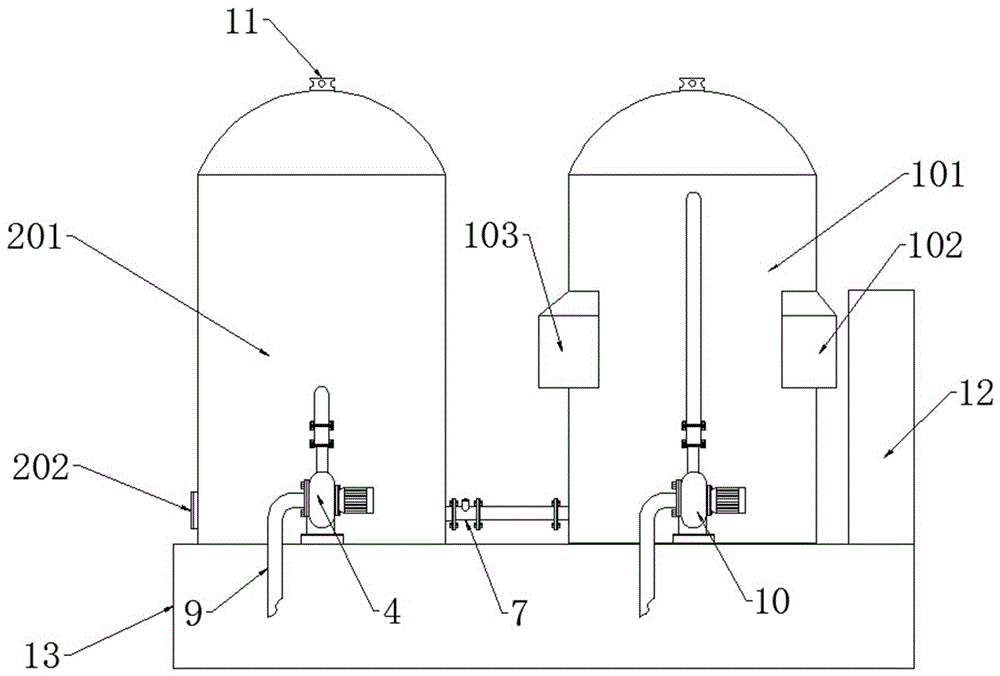

[0039] A kind of cutting fluid circulation regeneration replenishment system, refer to the attached Figure 1-11 : comprising a waste liquid regeneration device 1 and an automatic replenishment device connected by a drain pipe 9,

[0040] The waste liquid regeneration device 1 includes a reaction kettle 101, an inner tank 104, a viscous adsorption collection device 109, a metal adsorption collection device 108, a reflux device, and a pump body. The cavity is sequentially provided with a metal adsorption collection device 108, a sticky matter adsorption collection device 109 and a reflux device;

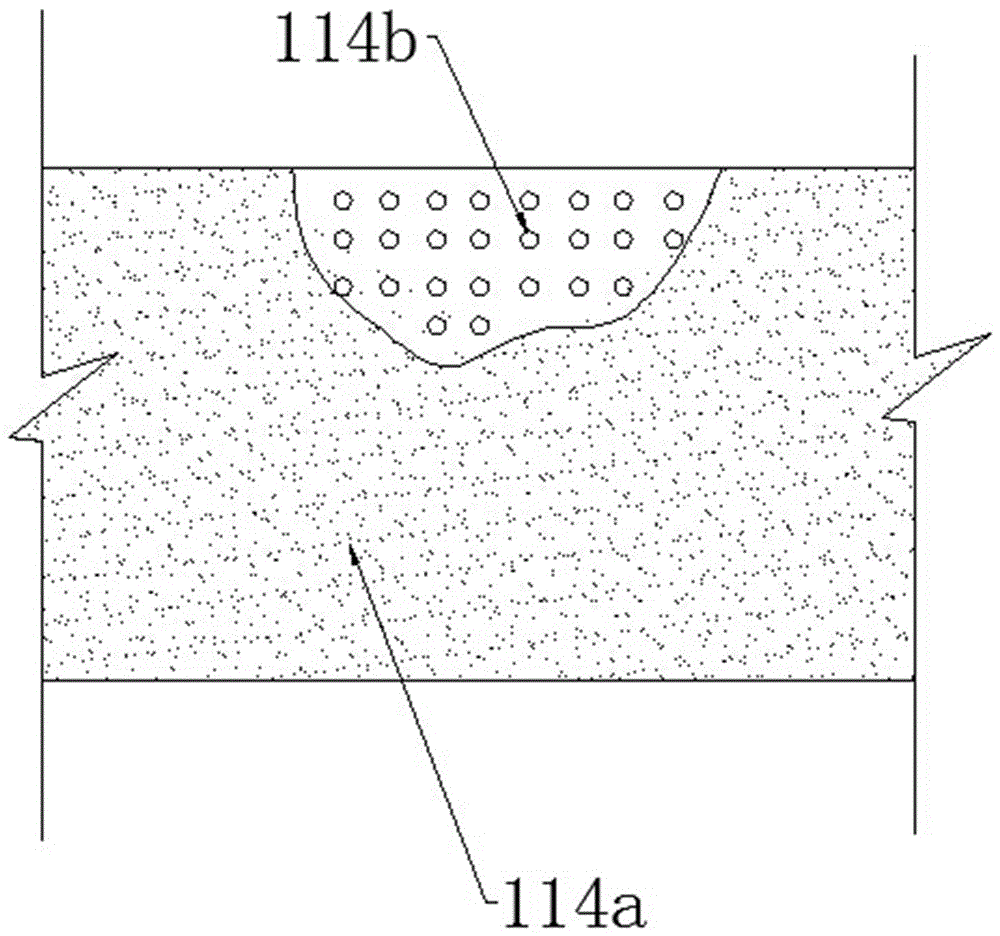

[0041] The metal adsorption collecting device 108 comprises a metal adsorption conveying device and a scraper 107, two supporting rollers 113 corresponding to each other are installed in cooperation with a magnetic conveying belt 112 to form a metal adsorbing conveying device, and the magnetic conveying belt 112 is provided with filter holes; one of the supporting rollers 113 Corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com