Vacuum device, attraction device, and conductive thin film manufacturing device

A technology of adsorption device and vacuum device, which is applied in semiconductor/solid-state device manufacturing, vacuum evaporation coating, and holding device for application of electrostatic attraction, etc. It can solve the problems that the film growth rate cannot be increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention was conceived to solve the above-mentioned disadvantages of the prior art, and aims to provide a technique capable of stably growing a conductive film on a dielectric substrate.

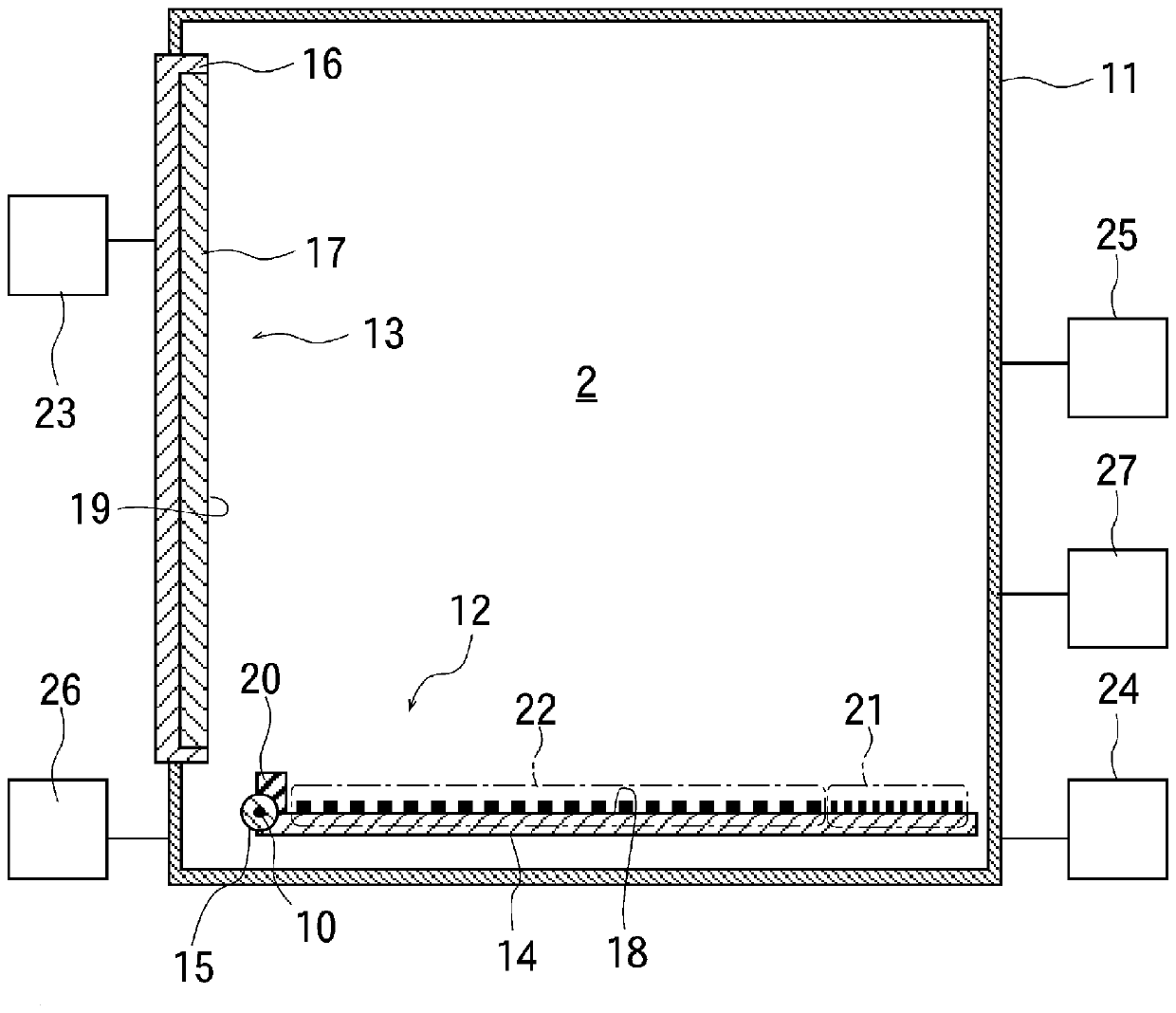

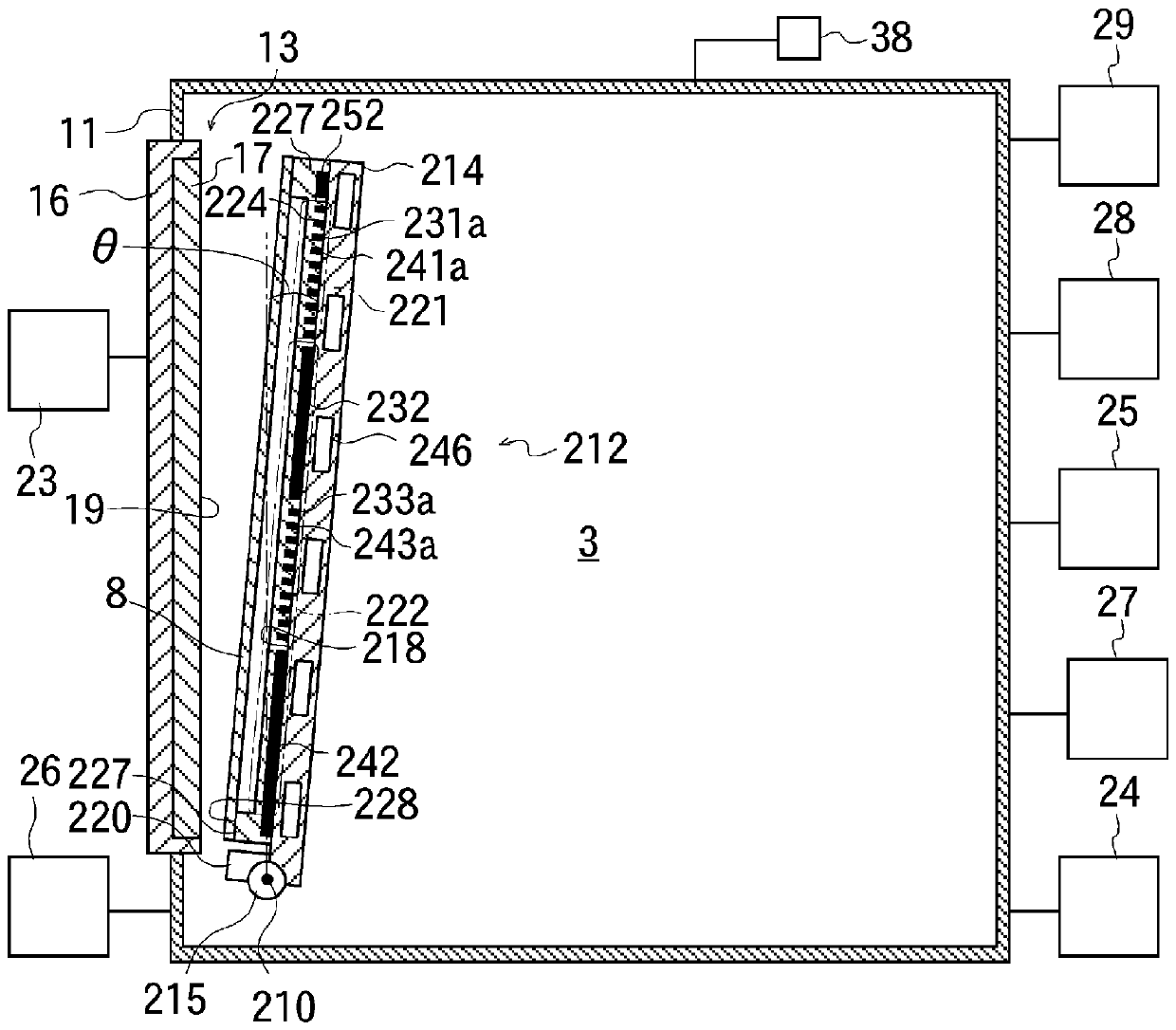

[0077] figure 1 The symbol 2 in the symbol 2 shows the vacuum device of the present invention, which has a vacuum chamber 11 , an adsorption device 12 and a target device 13 .

[0078] A rotating device 26 such as a motor and a sputtering power source 23 are disposed outside the vacuum chamber 11 .

[0079] The target device 13 has a sputtering target 17 to be sputtered and a cathode electrode 16 on which the sputtering target 17 is mounted, and the cathode electrode 16 is connected to a sputtering power supply 23 .

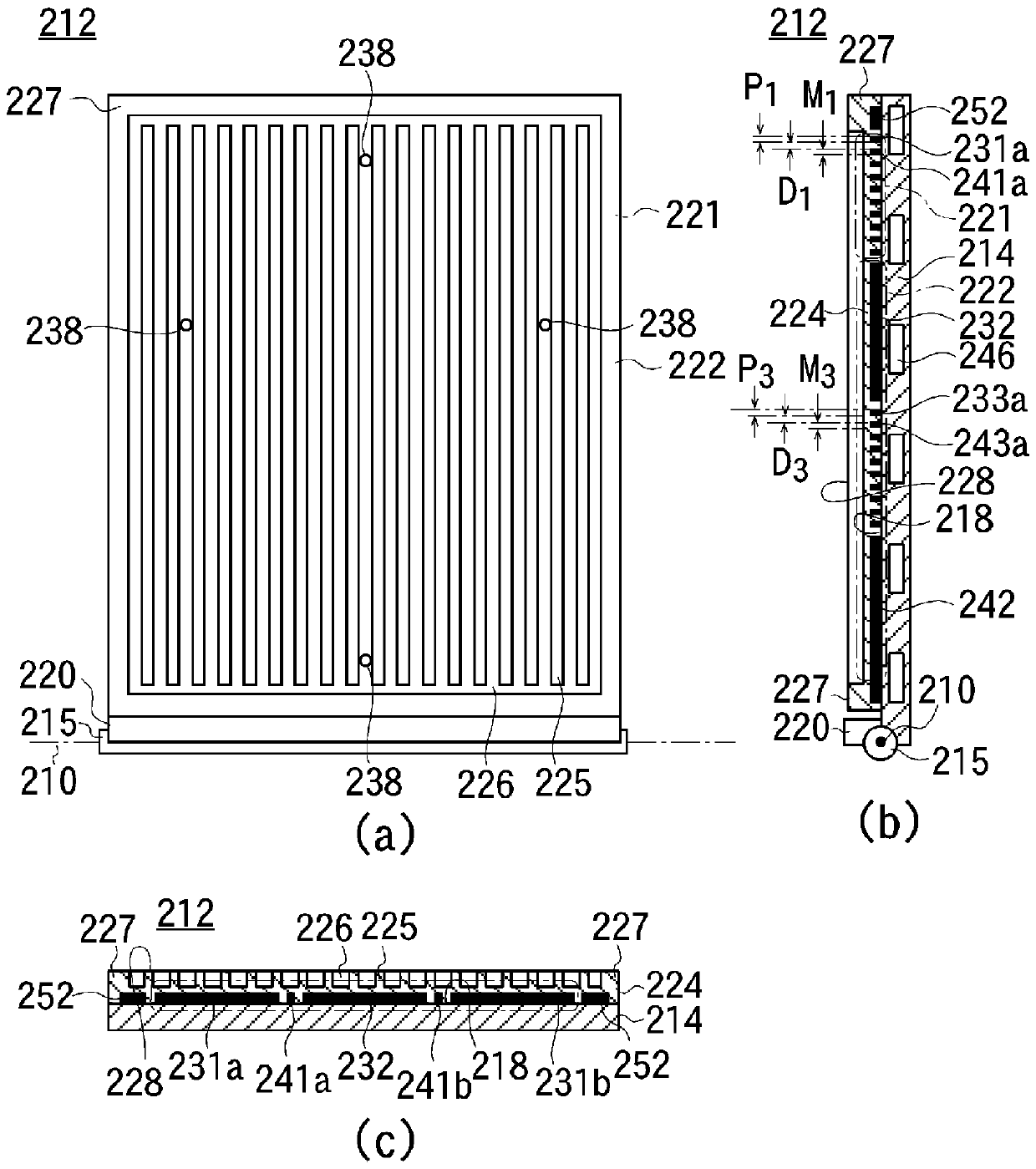

[0080] The adsorption device 12 has a rectangular or square adsorption plate 14 and a rod-shaped rotating shaft 15 arranged on one side of the adsorption plate 14. The rotating shaft 15 is connected to the rotating device 26, and the rotating shaft 15 rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com