Tunnel grouting equipment and technology

A technology of grouting and tunneling, which is applied in the direction of tunnels, tunnel linings, mining equipment, etc., can solve the problems that are easy to cause quicksoil, quicksand, impact, collapse and instability of the tunnel top and side wall surrounding rock, and achieve relative position stability, Effect of reducing environmental pollution and maintaining permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

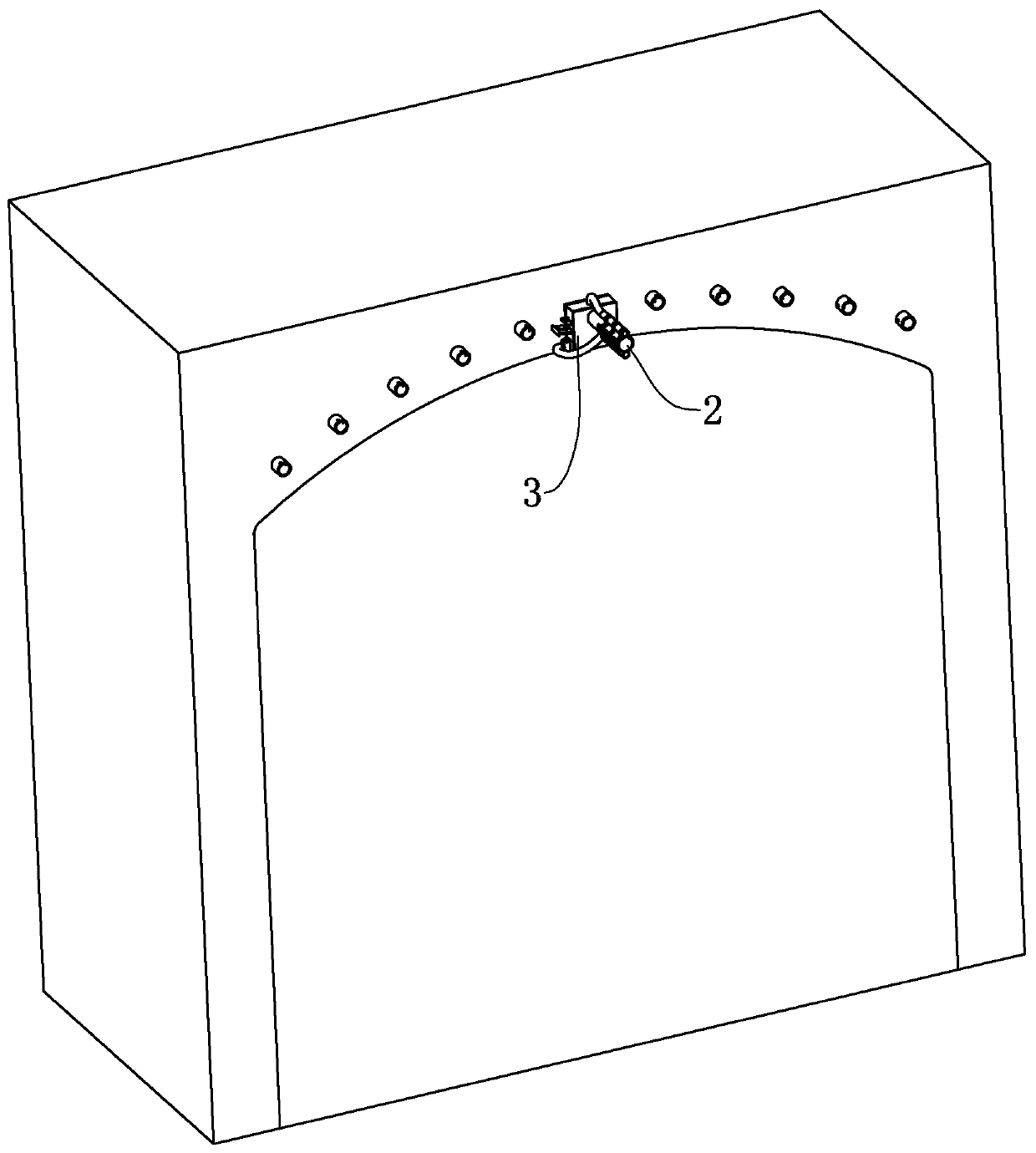

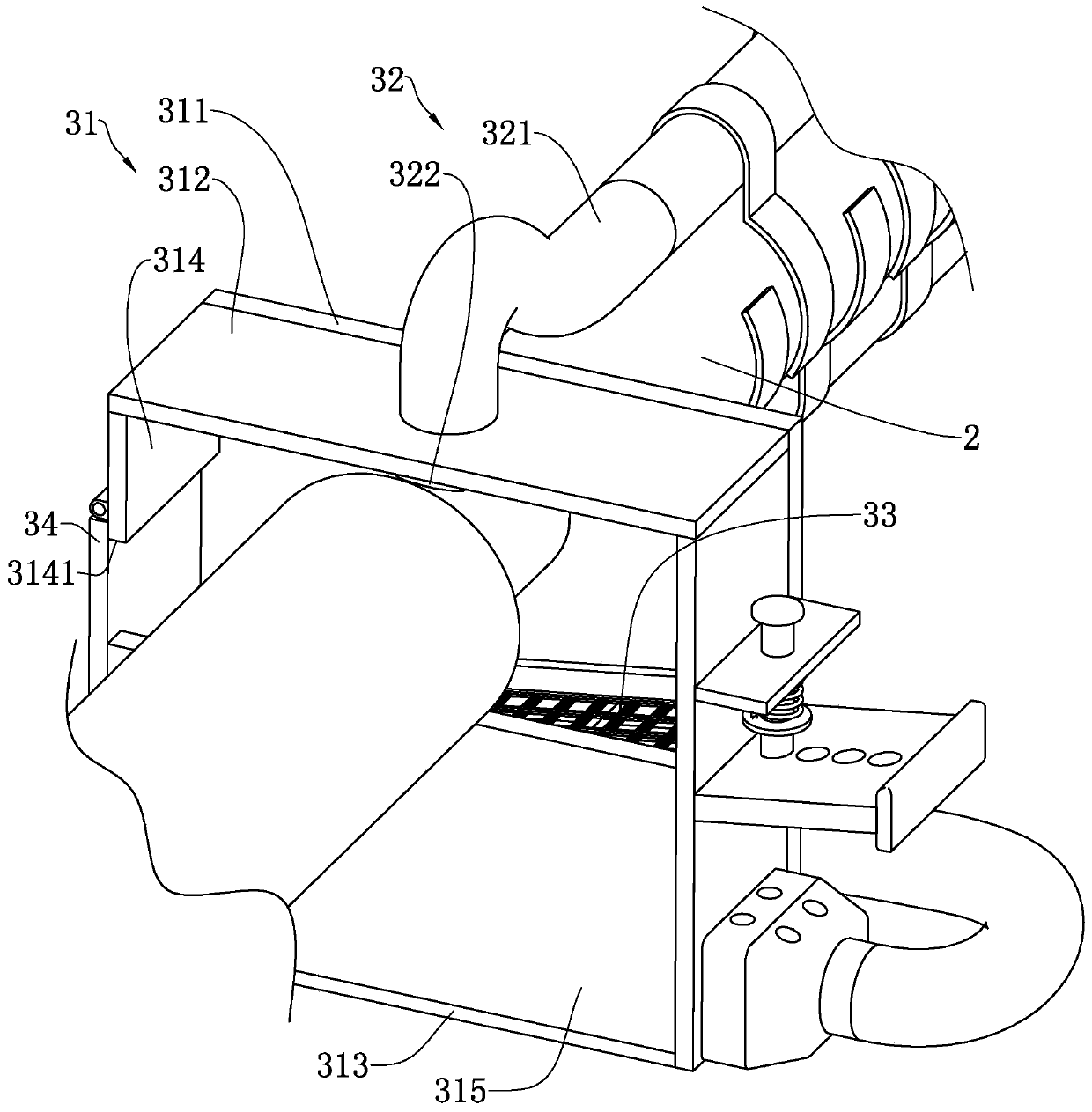

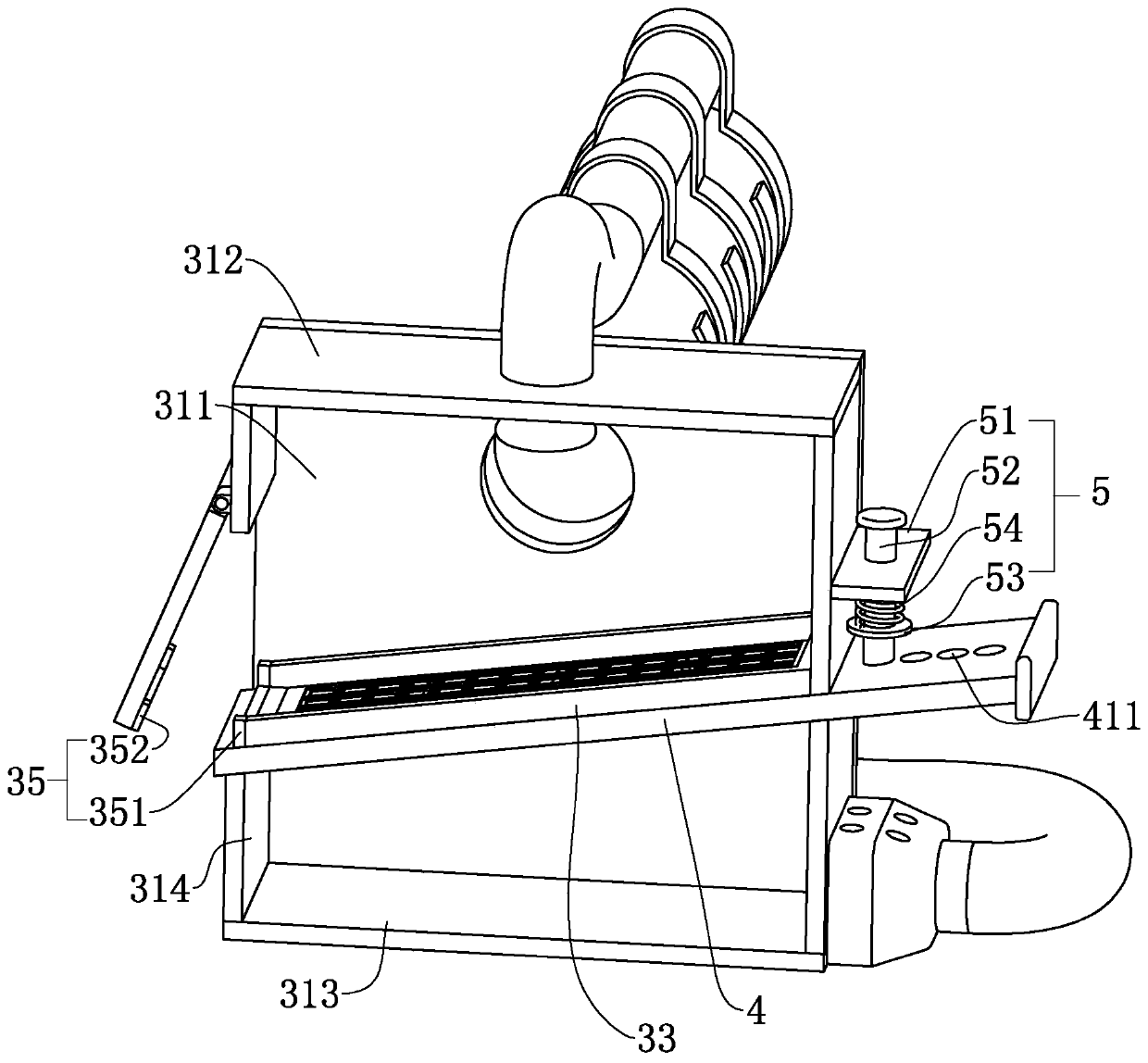

[0040] refer to figure 1 and figure 2 , discloses a tunnel grouting equipment for the present invention, including a blowpipe 2, a dust suppression mechanism 3 is arranged on the blowpipe 2, the dust suppression mechanism 3 includes a buckle cover 31 fixed on the blowpipe 2, and the opening of the buckle cover 31 faces the direction of the air outlet of the blowpipe 2 , the buckle cover 31 includes a rear plate 311, the rear plate 311 is a square plate, the upper and lower ends of the same surface of the rear plate 311 are respectively integrally formed with an upper side plate 312 and a lower side plate 313, between the upper side plate 312 and the lower side plate 313 Two vertical side plates 314 fixed on the rear plate 311 are provided, the vertical side plates 314 are fixed with the upper side plate 312 and the lower side plate 313, and the buckle cover 31 includes the vertical side plate 313 fixed on the lower side plate 313 and the vertical side plate 314. The front pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com