A method for selectively separating and recovering tellurium from tellurium-containing materials

A technology of separation recovery and selectivity, which is applied in the field of metallurgy, can solve the problems of long recovery period, long process flow, lengthy and complicated process, etc., and achieve the effect of high selectivity, good separation effect and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

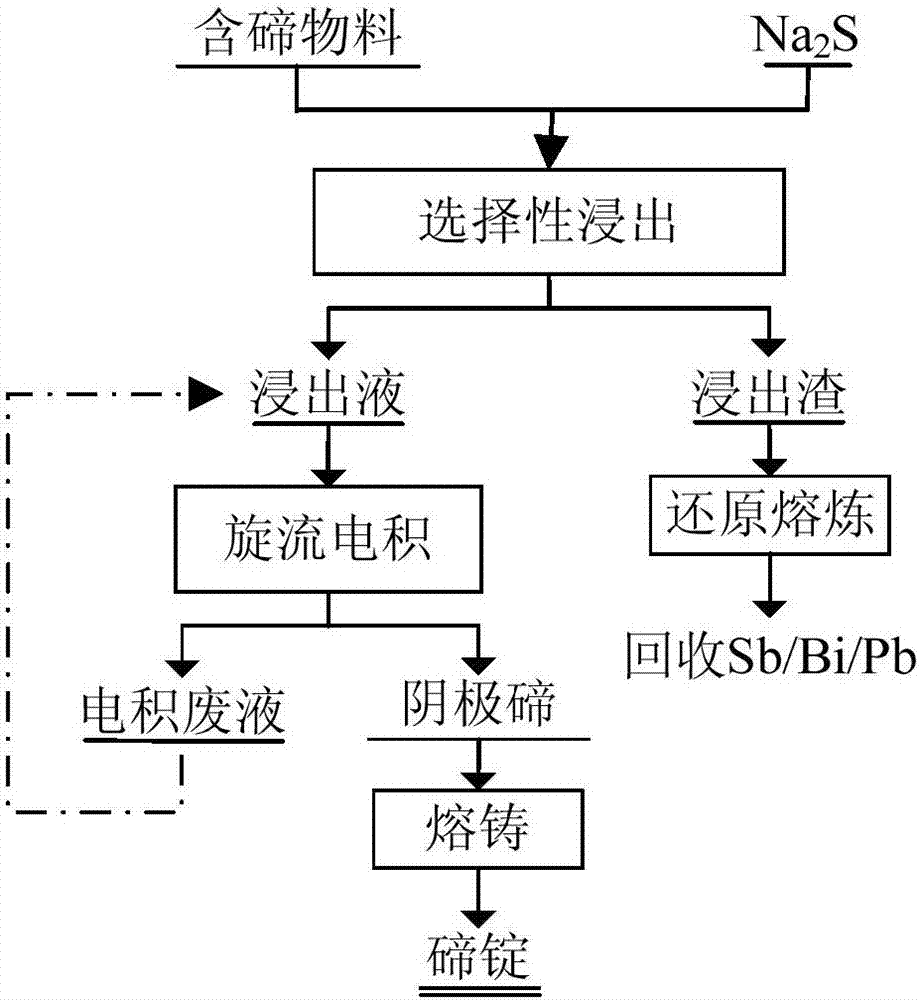

[0041] A method for selective separation and recovery of tellurium of the present invention, its process flow diagram is as follows figure 2 shown, including the following steps:

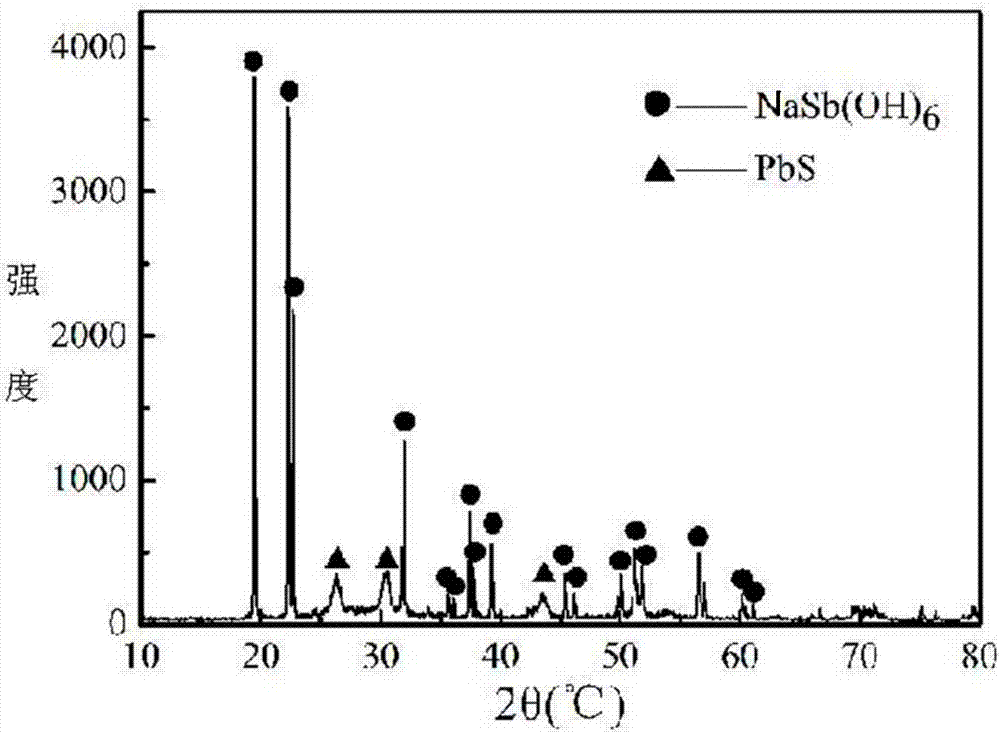

[0042](1) Grinding the tellurium-containing material with the chemical composition shown in Table 1 to 100% through a sieve with a pore size of 75um to 150um, then adding the sieved tellurium-containing material into the prepared 50g / L sodium sulfide solution (sulfurization The volume of the sodium solution and the mass ratio of the tellurium-containing material are 8L / Kg), stirring and leaching, the temperature during the leaching process is 30 ° C, and the leaching time is 4 hours. Slag (see its XRD pattern image 3 ), the leach slag is recovered by traditional reduction smelting to recover antimony, bismuth and lead;

[0043] (2) Add the leaching solution after step (1) into the circulating electrolytic cell for swirl electrolysis, control the circulating flow rate to 300L / h, and the current d...

Embodiment 2

[0047] A method for selective separation and recovery of tellurium of the present invention, its process flow diagram is as follows figure 2 shown, including the following steps:

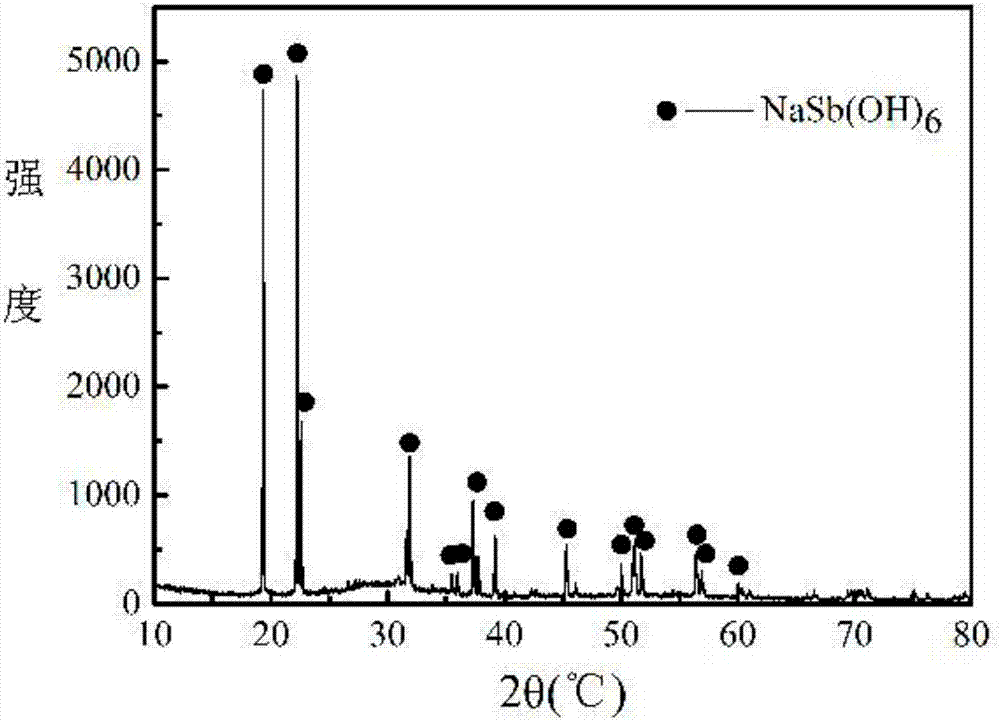

[0048] (1) Grinding the tellurium-containing material with the chemical composition as shown in Table 1 to 100% through a sieve with a pore size of 75um to 150um, and then adding the sieved tellurium-containing material into the prepared 30g / L sodium sulfide solution (sulfurization The volume of the sodium solution and the mass ratio of the tellurium-containing material are 5L / Kg), stirring and leaching, the temperature during the leaching process is 60 ° C, and the leaching time is 3 hours. Slag, leaching slag using traditional reduction smelting to recover antimony, bismuth and lead;

[0049] (2) Add the leaching solution after step (1) into the circulating electrolytic cell for swirl electrolysis, control the circulating flow rate to 400L / h, and the current density to 40A / m 2 ; During the elec...

Embodiment 3

[0053] A method for selective separation and recovery of tellurium of the present invention, its process flow diagram is as follows figure 2 shown, including the following steps:

[0054] (1) Grinding the tellurium-containing material with the chemical composition shown in Table 1 to 100% through a sieve with a pore size of 75um to 150um, and then adding the sieved tellurium-containing material into the prepared 20g / L sodium sulfide solution (sulfurization The volume of the sodium solution and the mass ratio of the tellurium-containing material are 3.5L / Kg), stirring and leaching, the temperature in the leaching process is 70°C, and the leaching time is 1h. After the leaching is completed, vacuum filtration is used to separate the liquid from the solid, and the leachate and Leaching slag, using traditional reduction smelting to recover antimony, bismuth and lead;

[0055] (2) Add the leaching solution after step (1) into the circulating electrolytic cell for swirl electrolys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com