Transferring stitching device

A suture device and coil transfer technology, applied in textiles, papermaking, knitting, etc., can solve the problems of complicated procedures and many structural parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

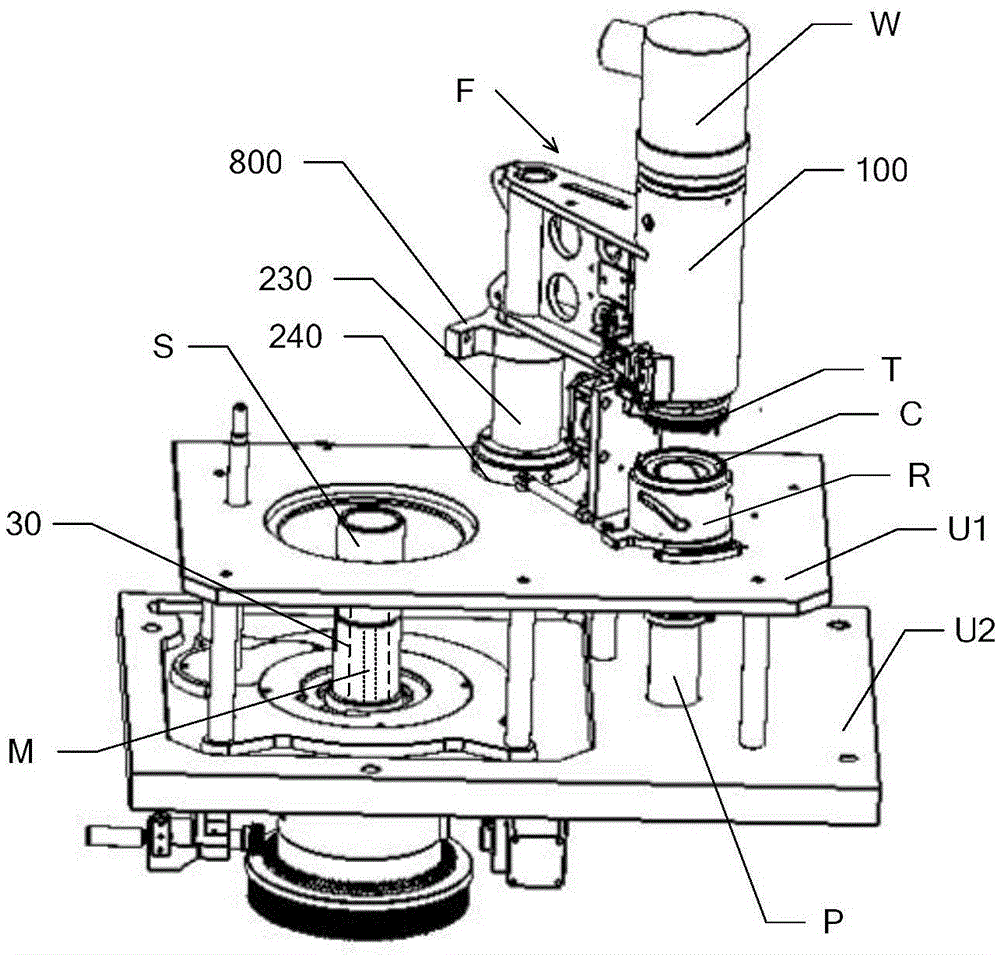

[0122]Step 800 includes: moving up the sock turning member M in the needle cylinder S to transfer the hosiery loop from the sock needle to the functional teeth and turning the sock, and then resetting the sock turning member M.

[0123] In this way, the hosiery loop can be transferred from the sock needle to the functional tooth and the sock can be turned over simply by moving up the sock turning member M, which greatly simplifies the process and structure. The structure of the sock member M is not limited, for example, it can be a solid rod member, a hollow pipe member and the like. However, in the process of transferring the socks from the needle cylinder S in the traditional method, a complex grabbing piece assembly must be used, wherein the grabbing piece is inserted on the sock line between the sock needles, so as to realize the transfer of the socks.

Embodiment 2

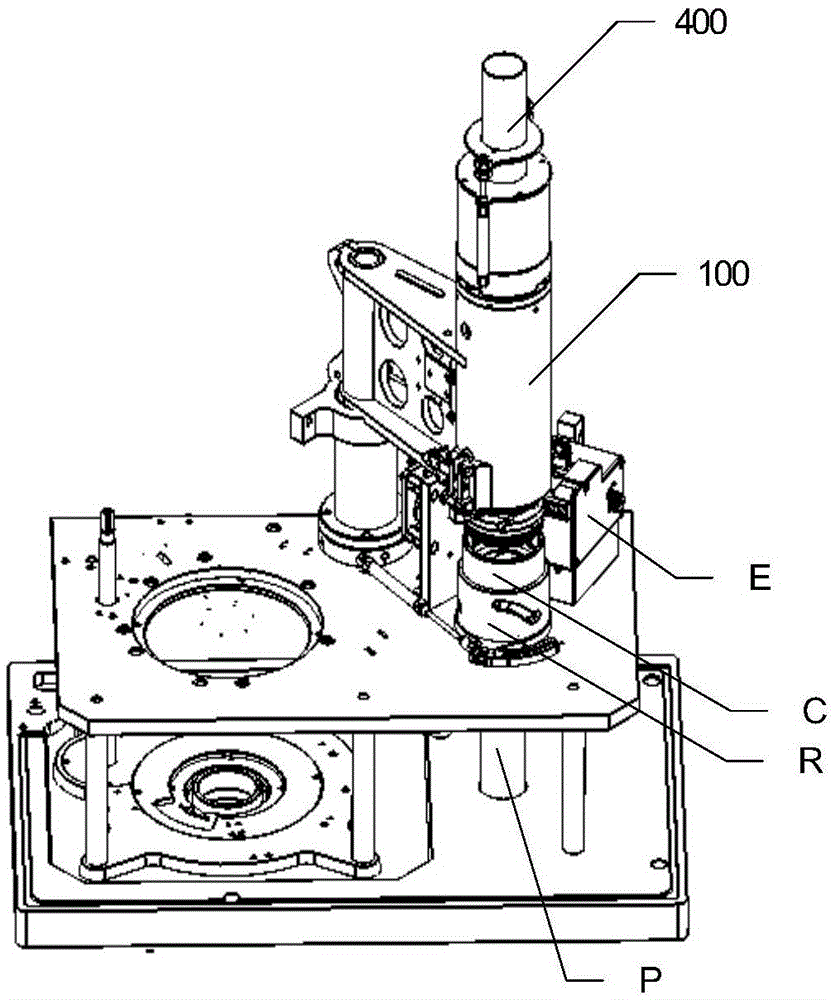

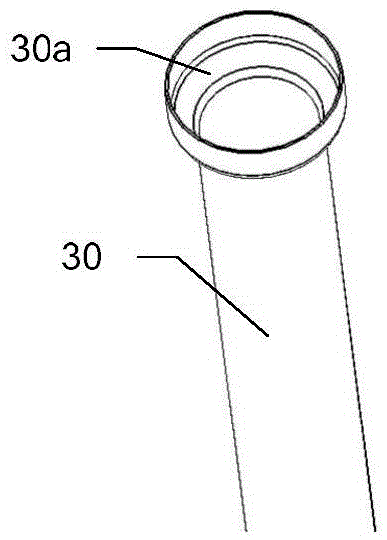

[0125] The transfer sewing device F can include an upper hosiery ring 400, a top hosiery tube 30 is provided in the syringe S, the lower end of the upper hosiery ring 400 or the upper end of the top hosiery tube 30 has a platform, and a sock turning part is arranged in the top hosiery tube 30 M.

[0126] Step 800 includes:

[0127] Step 810, move the upper sock part 400 downward and / or move the top sock tube 30 up so that the upper sock part 400 is in contact with the top sock tube 30, and then the upper sock part 400 moves up together with the top sock tube 30 to The hosiery loop is transferred from the hosiery needle to the functional teeth;

[0128] Step 820, reset the top sock tube 30, move up the sock turning part M in the needle cylinder S to turn the socks, and then reset the sock turning part M.

[0129] Because in step 810, the upper sock ring 400 moves upward together with the top sock tube 30 to complete the stitch transfer, it will be positioned above the stitche...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap