Component for metal belt of continuously variable transmission

A continuously variable transmission and component technology, applied in the direction of V-belt, belt/chain/gear, mechanical equipment, etc., can solve problems such as high stress, reduce torque loss, improve repetitive fatigue strength, and improve power transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, the present invention will be described in further detail through the embodiments shown in the drawings.

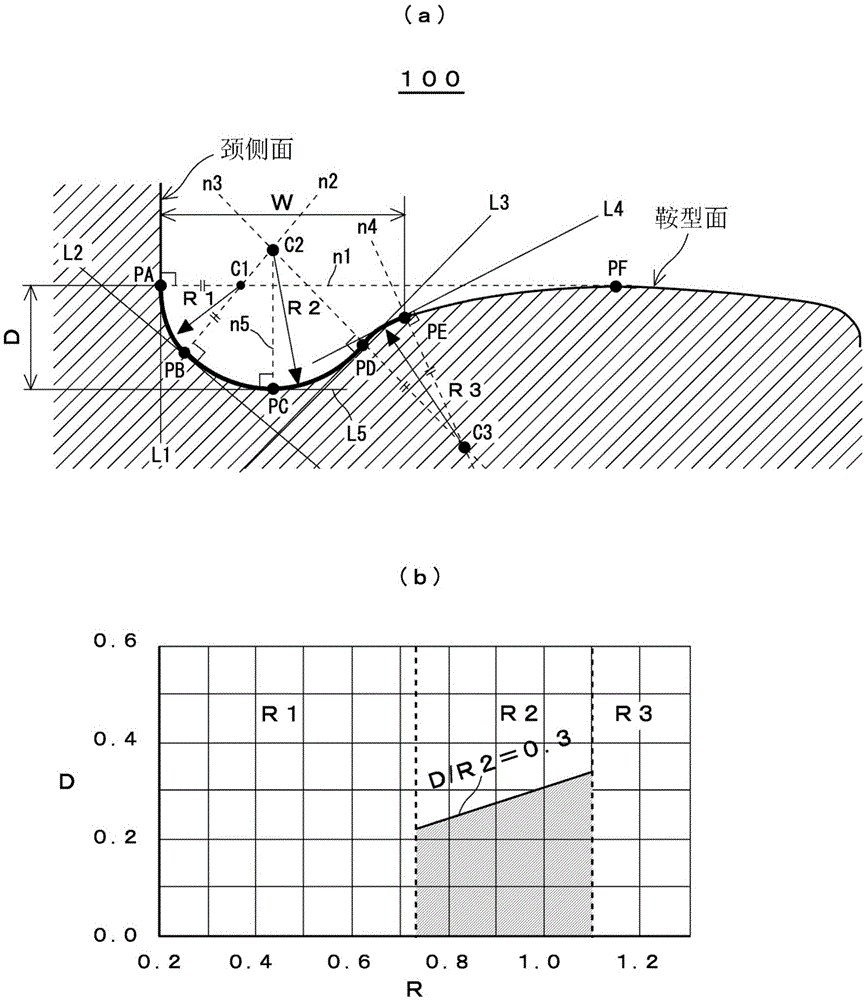

[0042] figure 1 It is an explanatory cross-sectional view of main parts showing the base of the neck of a metal belt element (hereinafter referred to as "element") 100 of the continuously variable transmission of the present invention. in addition, figure 1 (b) is a graph showing the correlation between each curvature radius R and depth D. In addition, the symbol D is the depth (distance) from the end of the saddle surface to the deepest part (point) PC, and the symbol W is the distance from the neck side to the R start point PE of the saddle surface.

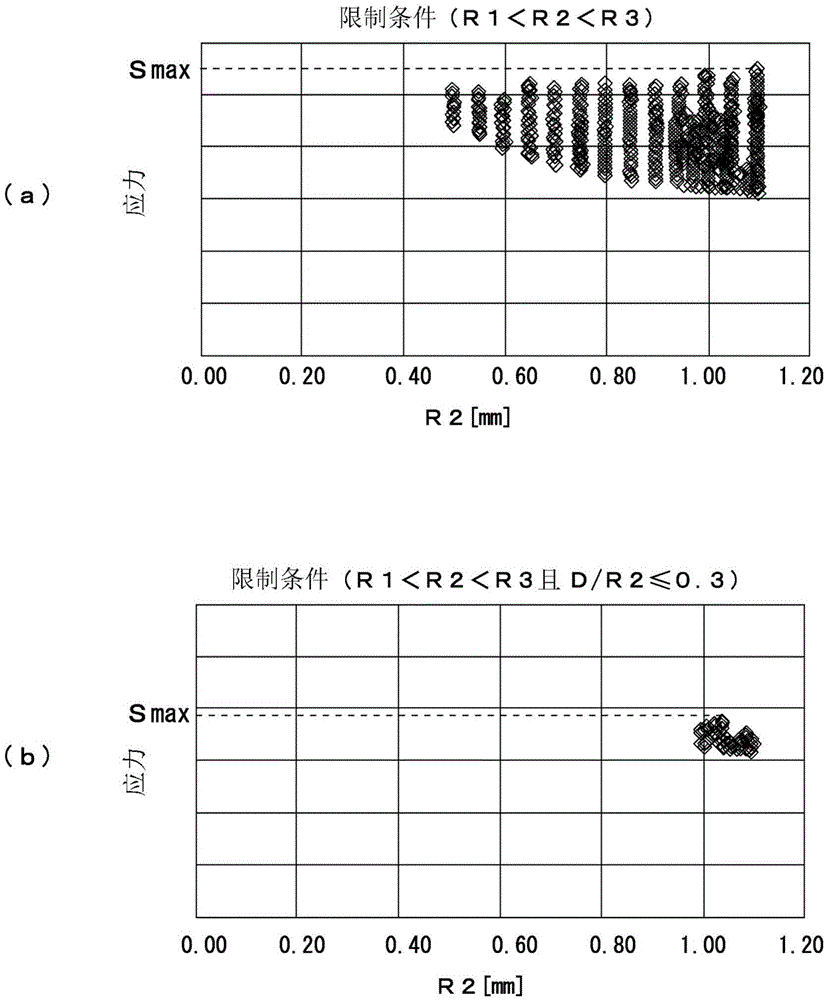

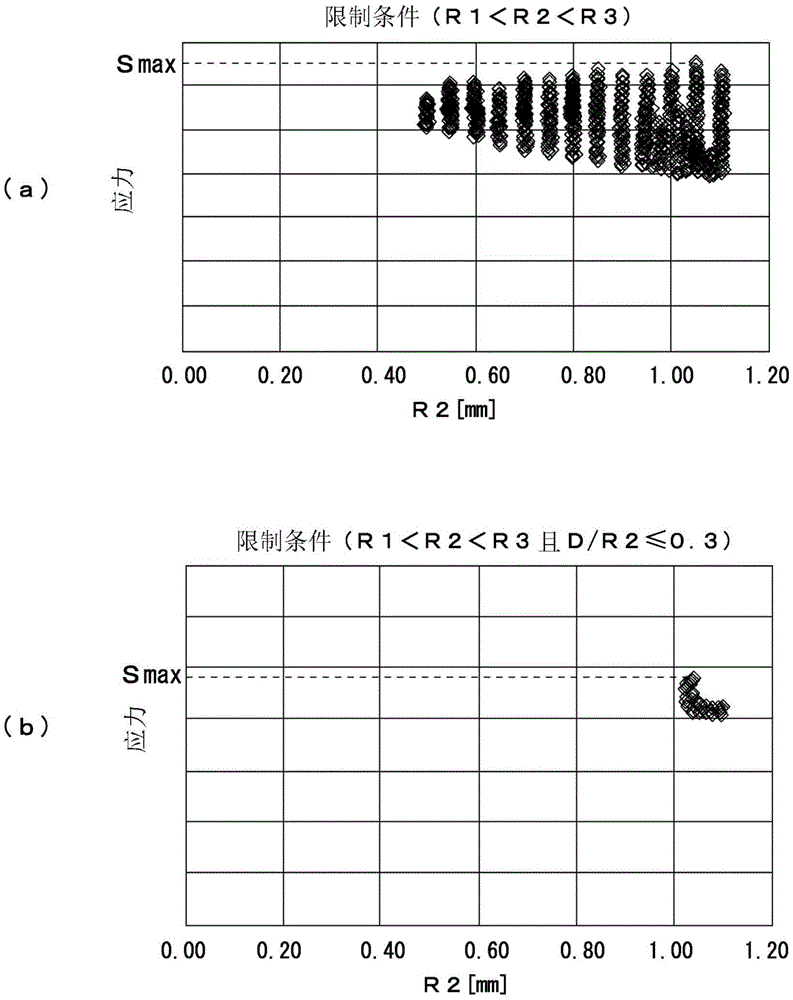

[0043] In this element 100, the connecting surface at the base of the neck that smoothly connects the saddle surface and the neck side is gradually increased from the neck side to the saddle surface, and the curvature radius R2 of the bottom surface depends on the curvature radius from the saddle su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com