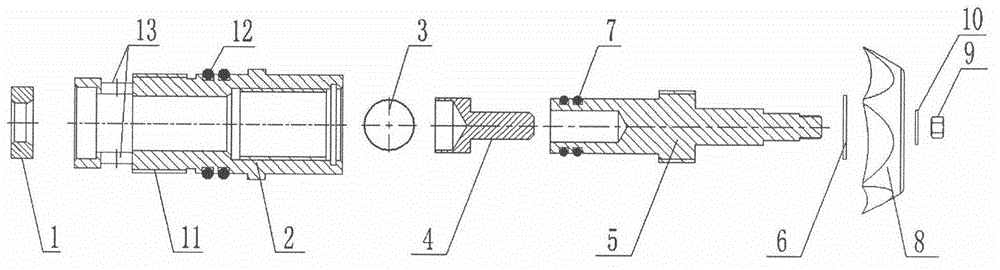

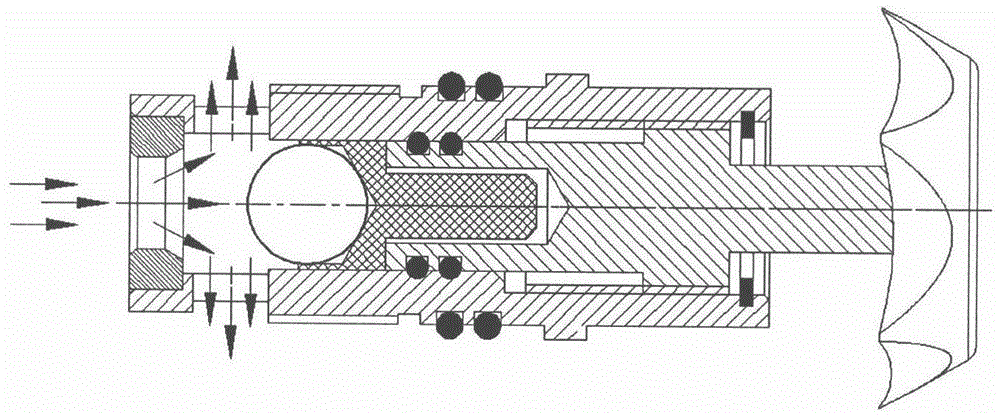

High-pressure exhaust valve for high-pressure airless sprayer

A high-pressure airless, exhaust valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of the machine not working normally, the high-pressure impact damage of the sphere and the soft sealing surface, etc., to achieve clever design and withstand high pressure. Strong, long-life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] When working, turn the handwheel 8 counterclockwise, and the handwheel 8 will drive the discharge valve screw 5 to rotate in the opposite direction to the discharge valve body 11, that is, the high-pressure discharge valve is opened, and the high-pressure material passes through the center hole of the base 1, pushing the ceramic ball 3 and fixing the ceramic ball The rod 4 is pushed away from the base 1, and air or other substances will be discharged from the machine body through the side hole 13 of the discharge valve body 11. After the air or other substances are exhausted, turn the hand wheel 8 clockwise to drive the discharge valve screw 5 to rotate in, and the discharge valve screw 5 pushes the ceramic ball fixing rod 4 and the ceramic ball 3 to move to the base 1 until the ceramic ball 3 is in contact with the base 1 The arc surfaces of the valves match and press tightly, that is, the discharge valve is closed. The circlip 6 controls the loosening distance of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com