A device and method for reducing evaporator frosting

An evaporator and frosting technology is applied in the field of devices for reducing the frosting of the evaporator, which can solve the problems of deteriorating the heat exchange effect of the evaporator, and achieve the effects of improving the cooling effect, simple and convenient operation, and prolonging the defrosting interval.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

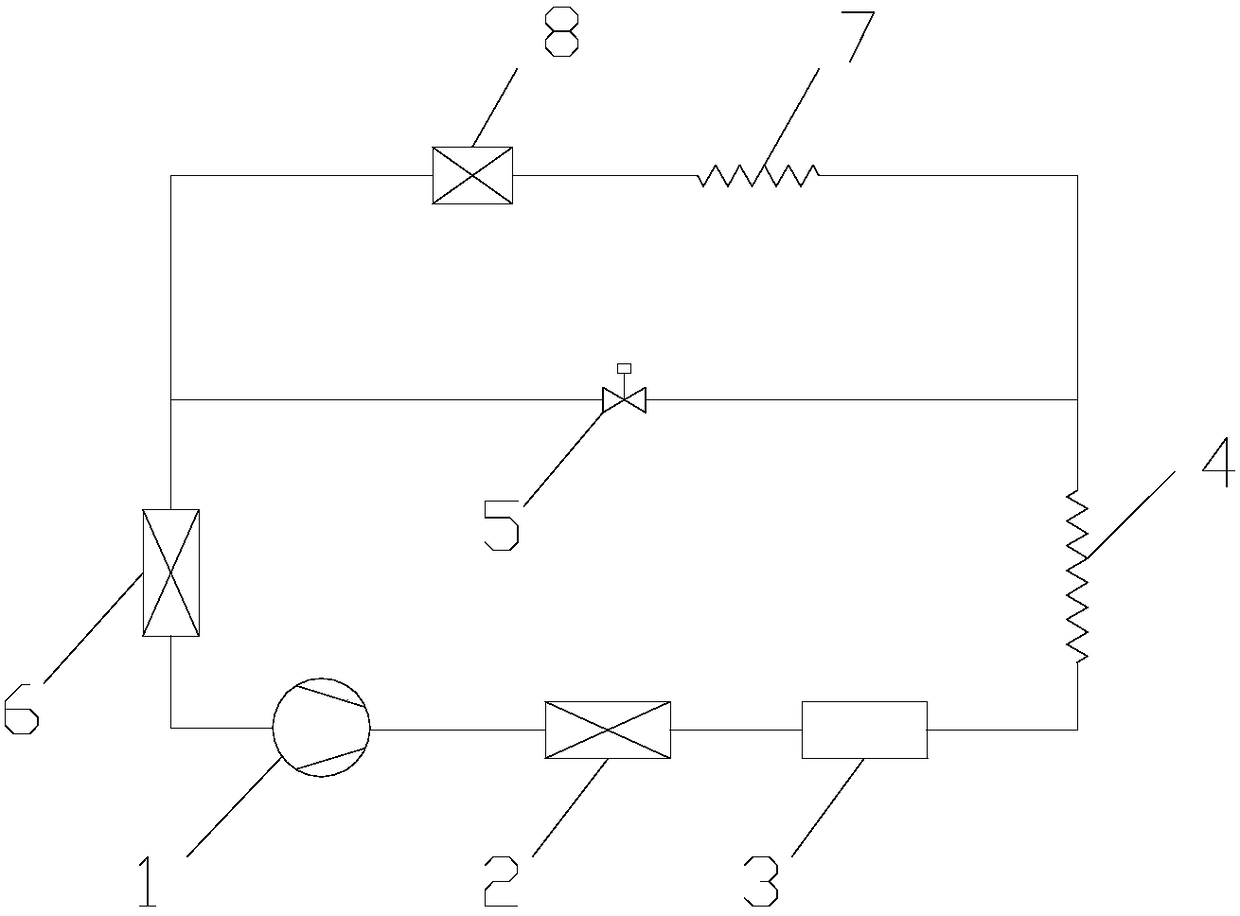

[0028] see figure 1 , this embodiment discloses a device for reducing frosting on the evaporator 6, which includes a compressor 1, a condenser 2, a dry filter 3, a capillary tube 4 and an evaporator 6 connected in sequence to form a refrigeration circuit, and the outlet end of the capillary tube 4 passes through Two parallel branch pipelines are connected to the inlet end of the evaporator 6, and the two parallel branch pipelines are respectively branch pipeline one and branch pipeline two. An auxiliary capillary 7 and a froster 8 are arranged in sequence along the refrigerant flow direction.

[0029] The froster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com