An alarm device for broken rollers used in orbital kilns

An alarm device and orbital kiln technology, applied in the field of orbital kiln, can solve the problems of multiple applications of detection components and sensors, complex maintenance and management, high probability of damage, etc., and achieve the effects of avoiding the influence of human factors, increasing economic benefits, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

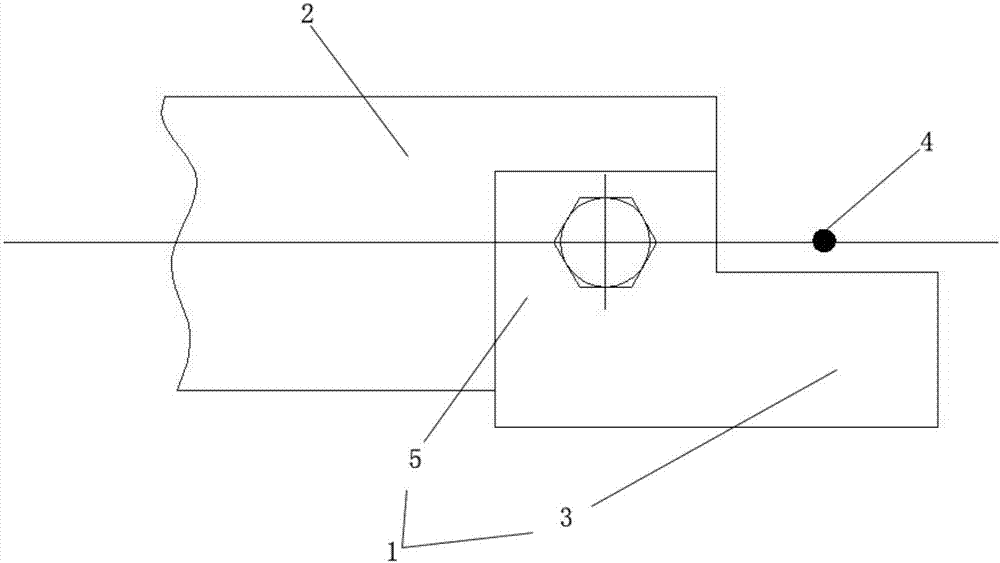

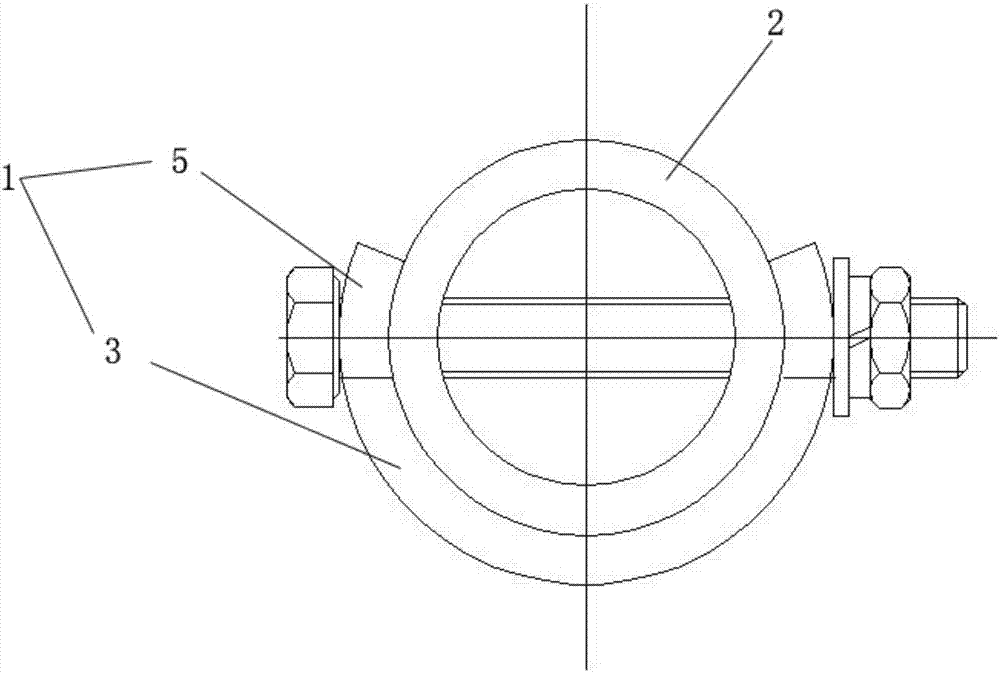

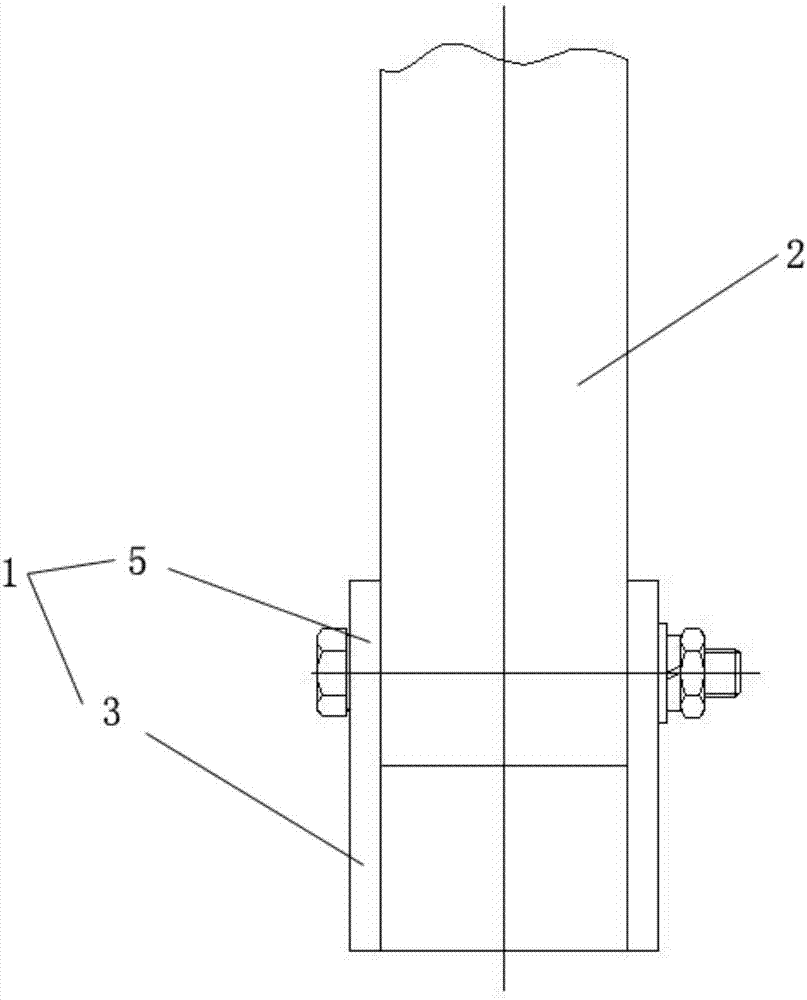

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to Figure 3 The shown invention is an alarm device for broken rollers used in orbital kilns, including a laser shield 1, a laser rangefinder and an alarm system. The laser shielding part 1 is matched with each roller bar 2 one by one and keeps coaxial rotation. The roller bar 2 is a silicon carbide structural part. The laser shielding part 1 is preferably made of stainless steel, and a fixing part can be set on the laser shielding part 1. 5. The fixed part 5 and the roller bar 2 are fixedly connected into one body. You can choose to use high-temperature glue for bonding, or use fasteners for fixed connection, or use ferrule-type or compression-type connection methods to ensure the fixed The connection structure between the part 5 and the roller bar 2 has good structural strength, good shock resistance, high temperature resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com