Effect Evaluation Method of Electroplating Copper Potion

An evaluation method and technology of electroplating copper, applied in the direction of electrochemical variables of materials, etc., can solve the problems of measurement accuracy affecting the reliability of conclusions, large workload, long test cycle, etc., to achieve rapid evaluation, short evaluation cycle, and small workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Bath solution to be tested: SkyPlate Cu627 from Tiancheng Chemical Co., Ltd., whose initial components before preparation are shown in Table 1, named Cu627 VMS (virgin make up solution).

[0036] Table 1

[0037] Element

concentration

CuSO 4 ·5H 2 o

85g / L

50%H 2 SO 4

440g / L

NaCl

90.5mg / L

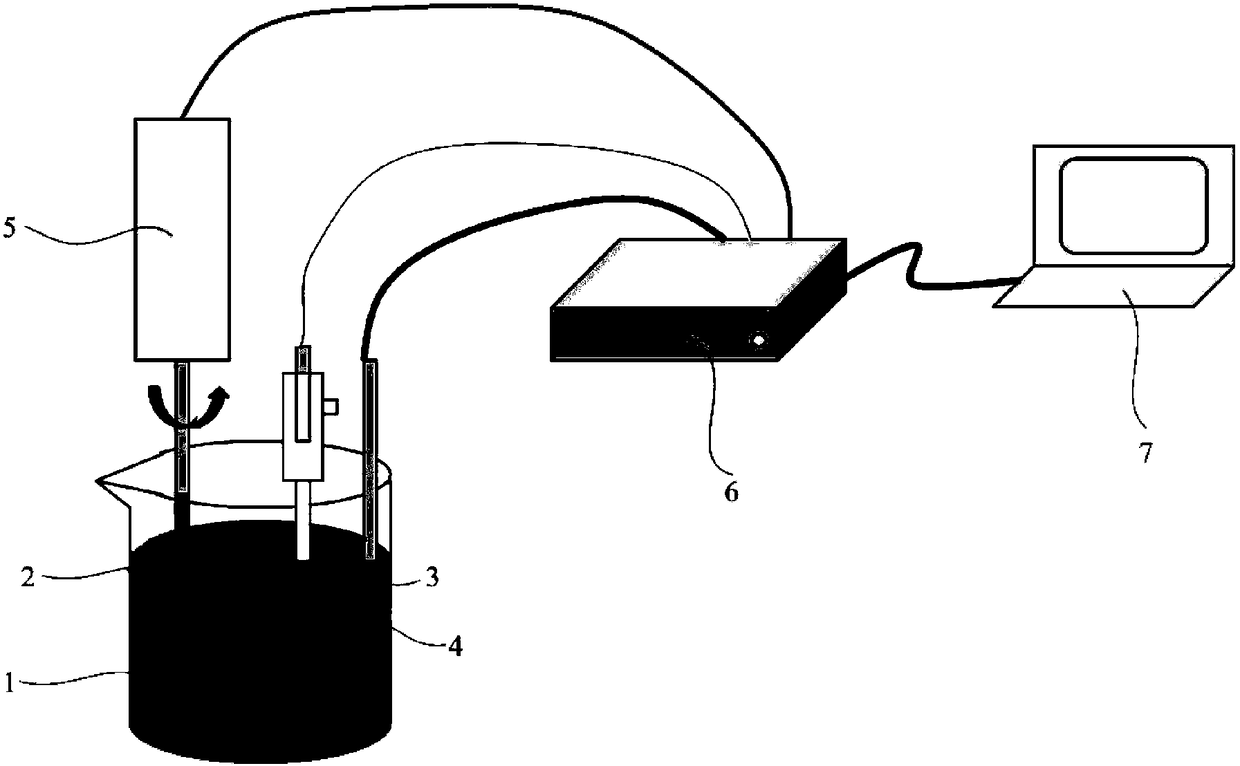

[0038] Analytical device: such as figure 1 As shown, the analysis device includes an analysis cup 1 and a working electrode 2 inserted into the analysis cup 1, a reference electrode 3 and an auxiliary electrode 4, the upper end of the working electrode 2 is provided with a rotating electrode device 5, the working electrode 2, the reference electrode 3 and the The auxiliary electrodes 4 are electrically connected to the electrochemical workstation 6 respectively, the reference electrode 3 is connected to the copper electroplating solution in the analysis cup 1 through the salt bridge, and the electrochemical workstation 6 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com