Multi-atmosphere dynamic thermogravimetric-differential thermal analyzer and application thereof in sulfur transfer performance simulation and evaluation of flue gas

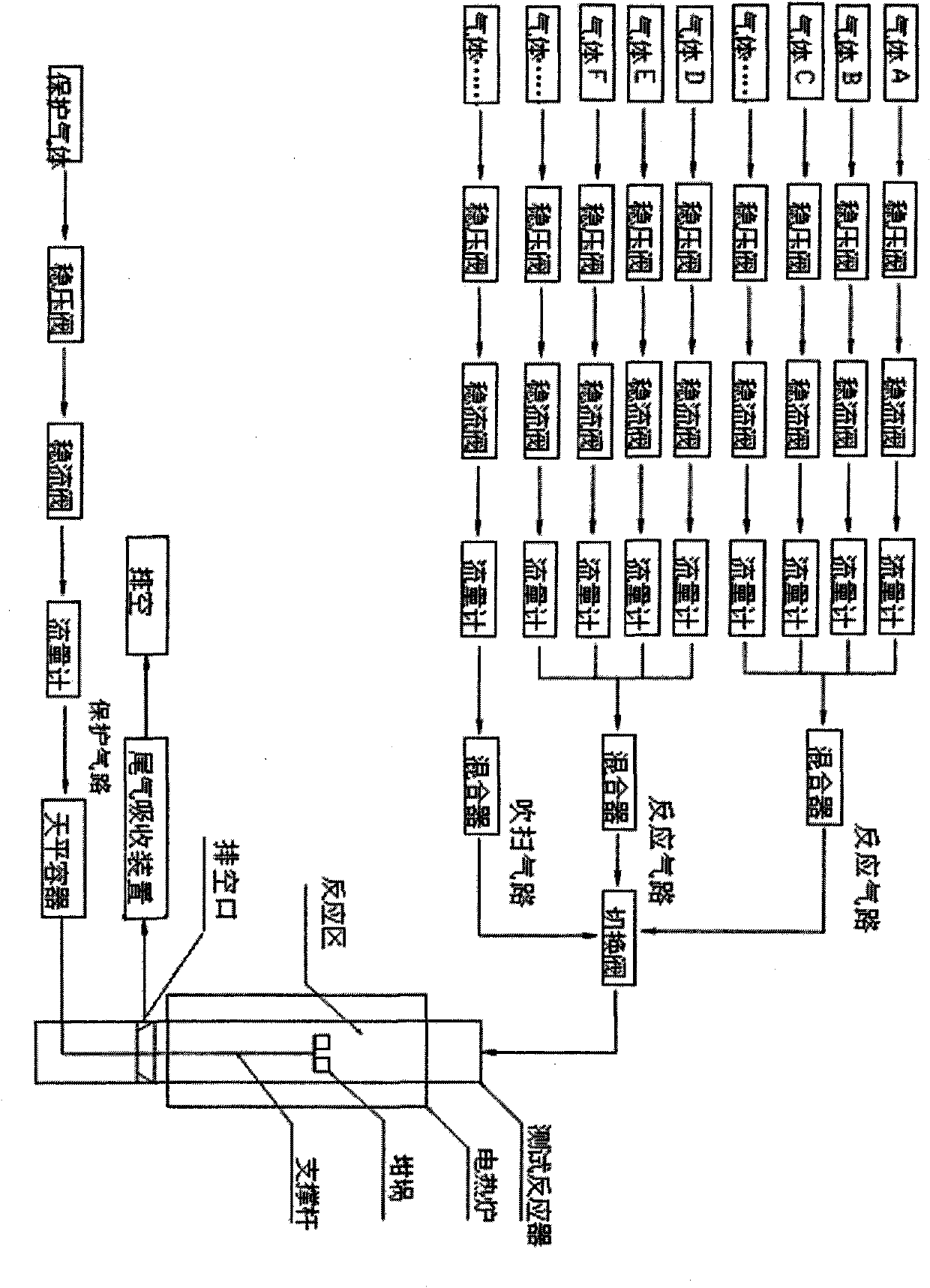

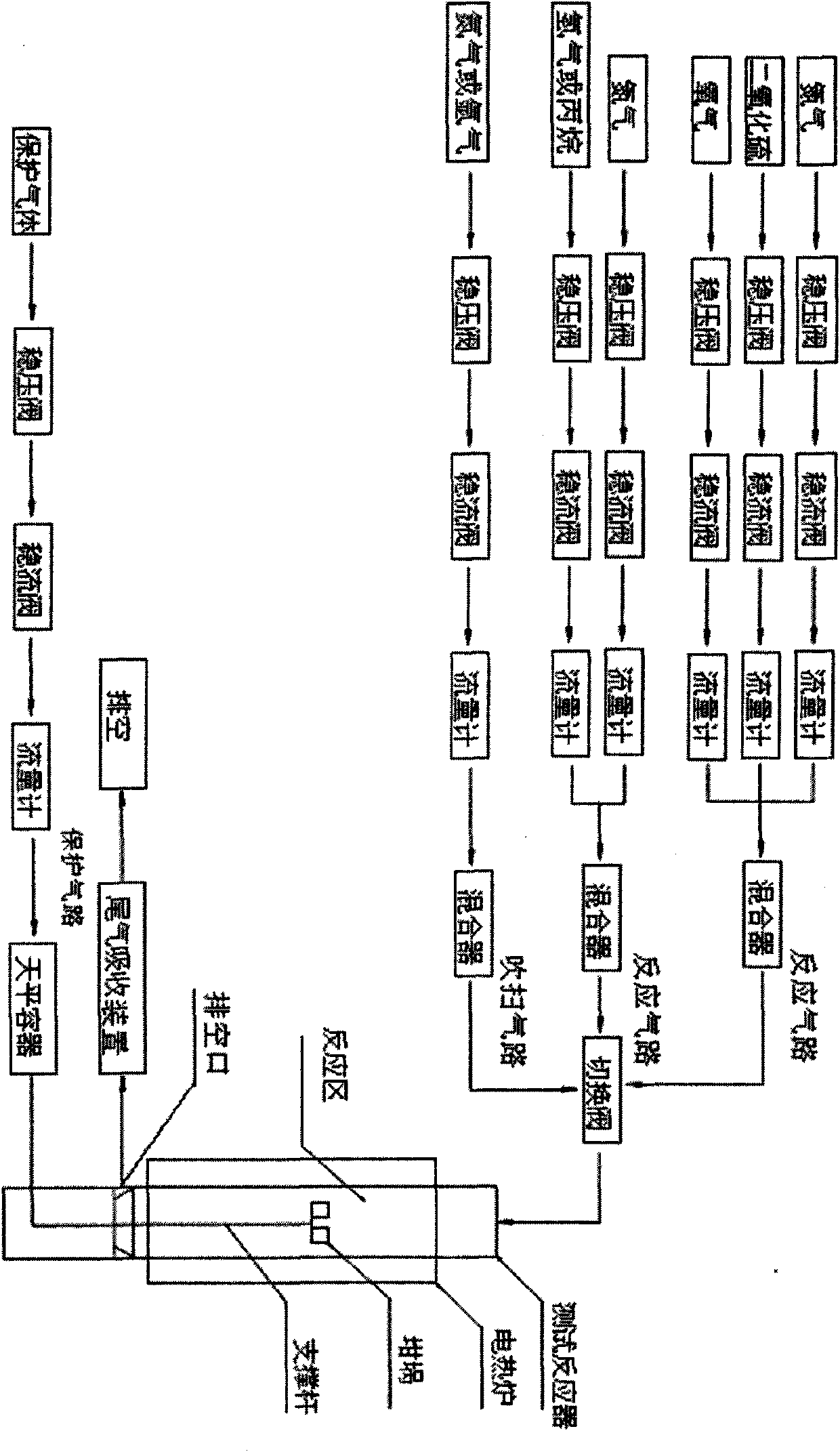

A technology of differential thermal analysis and thermogravimetry, which is applied in the field of oil refining industry, can solve the problems of simple gas path, high cost, monotonous switching mode, etc., and achieve the effect of strong simulation ability, research means and rapid evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

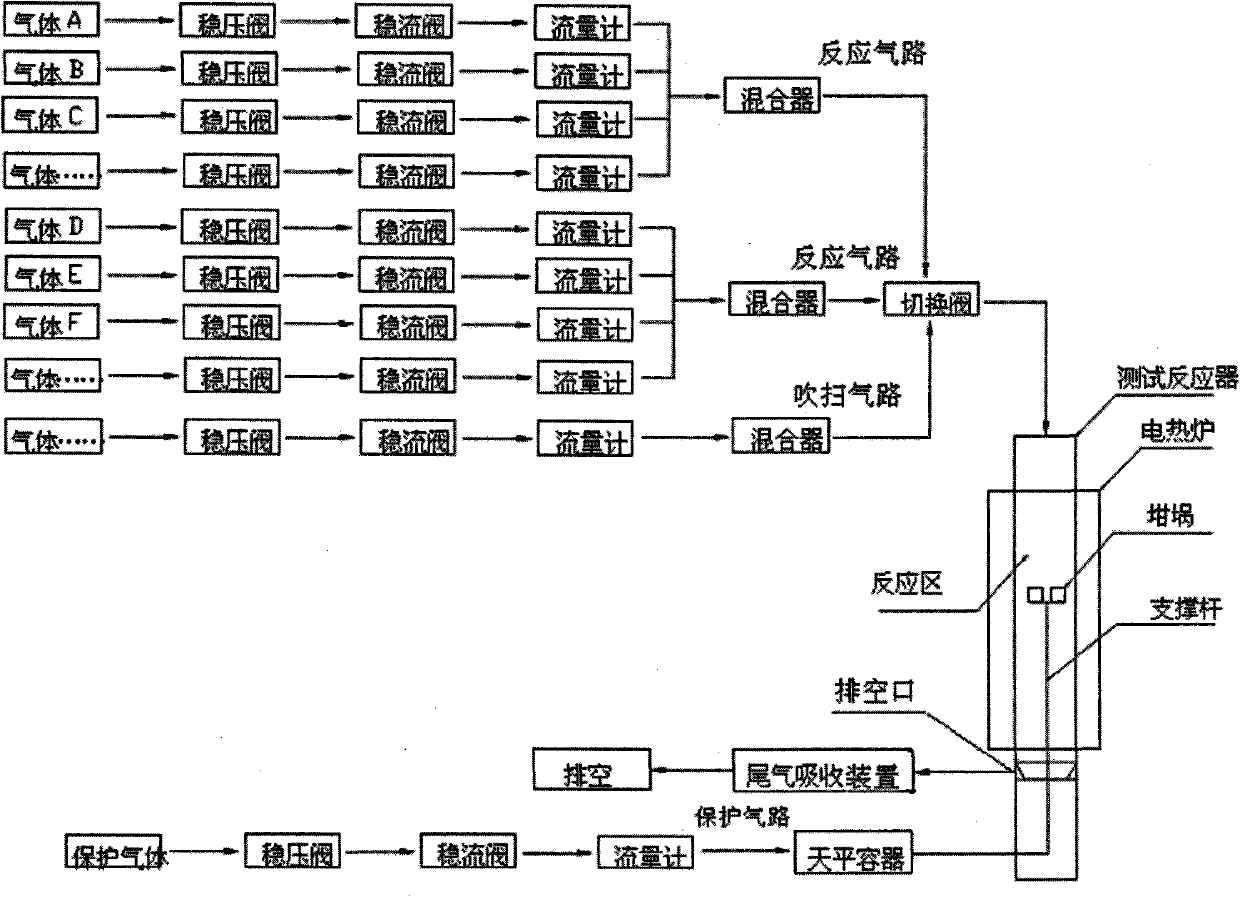

[0019] Such as figure 2 As shown, the process of sulfur dioxide being oxidatively adsorbed to form sulfate under the action of the sulfur transfer agent is simulated by using the various atmosphere dynamic thermogravimetric-differential thermal analyzers of the present invention. Put the crucible containing the sulfur transfer agent sample on the sample support rod, and put the reference crucible in place, after assembling the test reactor and all the gas circuits, pass through the pressure stabilizing valve, steady flow valve and flow meter to the balance container The protective gas nitrogen enters the test reactor from the lower end; the purge gas nitrogen is introduced from the upper end of the test reactor through the pressure stabilizing valve, steady flow valve, flow meter and mixer to replace the system air; Protective gas, the switching valve switches the purge gas path to the reaction gas path, and the reaction gases nitrogen, sulfur dioxide, and oxygen pass through...

Embodiment 2

[0021] Such as figure 2As shown, the process in which sulfur dioxide is oxidized and adsorbed by the sulfur transfer agent to form sulfate and then reduced to hydrogen sulfide is simulated by using the various atmosphere dynamic thermogravimetric-differential thermal analyzers of the present invention. Put the crucible containing the sample of sulfur transfer agent on the sample support rod, and put the reference crucible, after assembling the test reactor and all the gas circuits, pass the pressure regulator valve, the steady flow valve and the flow meter to the balance container. The protective gas argon enters the test reactor from the lower end; the purge gas argon is introduced from the upper end of the test reactor through the pressure stabilizing valve, steady flow valve, flow meter and mixer to replace the system air; after the replacement is clean, keep constant The protective gas and purge gas of the flow rate, the electric furnace is programmed to heat up to the te...

Embodiment 3

[0023] Such as figure 2 As shown, the process in which sulfur dioxide is oxidized and adsorbed by the sulfur transfer agent to form sulfate and then reduced to hydrogen sulfide is simulated by using the various atmosphere dynamic thermogravimetric-differential thermal analyzers of the present invention. Put the crucible containing the sample of sulfur transfer agent on the sample support rod, and put the reference crucible, after assembling the test reactor and all the gas circuits, pass the pressure regulator valve, the steady flow valve and the flow meter to the balance container. The protective gas nitrogen enters the test reactor from the lower end; the purge gas argon is introduced from the upper end of the test reactor through the pressure stabilizing valve, steady flow valve, flow meter and mixer to replace the system air; after the replacement is clean, a constant flow rate is maintained The protective gas and purge gas are used, the electric furnace is programmed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com