Bendable flexible dimming window film for changing transmittance of light

A light transmittance and flexible technology, applied in the field of dimming film, can solve the problems of inflexibility, hard texture and heavy quality of dimming glass, and achieve the effect of easy bending, soft texture and good environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

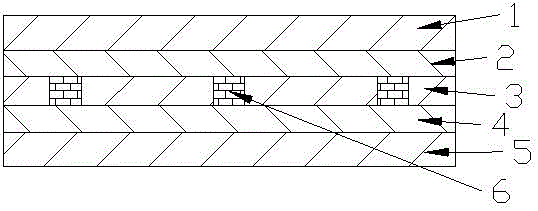

[0021] see figure 1 As shown in the bendable flexible dimming window film that changes light transmittance, the upper flexible transparent conductive film includes a flexible transparent substrate layer 1, namely a PET layer and a transparent electrode layer 2, namely an AZO layer, and the upper flexible transparent conductive film includes a flexible transparent substrate Layer 5 is the PET layer and transparent electrode layer 4 is the AZO layer. The transparent electrode layer 2 is opposite to the transparent electrode layer 4, and the gap between them is 20 μm. Between the two opposite transparent electrode layers, there is a tiny glass 6 of the same height that separates the transparent electrode layers on both sides. Between the two transparent electrode layers on the outer periphery of the glass is polyparabenamide 3. 3 is sandwiched between two transparent electrode layers 2,4. The two relatively transparent electrode layers are respectively connected to the two pole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com